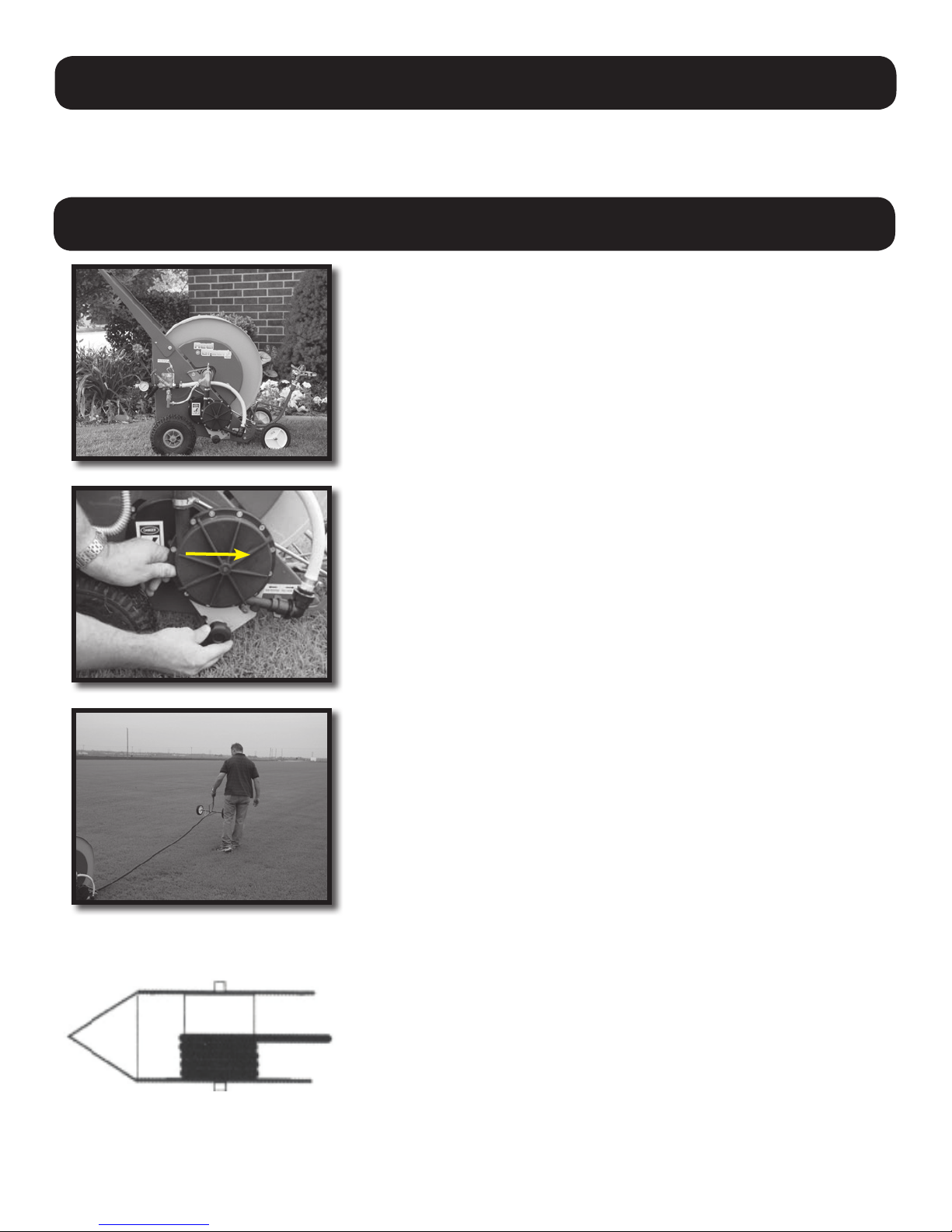

5) Re-engage the turbine assembly by loosening the black knob

again and sliding the turbine bracket back into place as shown

by white arrow, so that the drive gears mesh. Tighten the black

lock knob again to hold the turbine in place.

IMPORTANT: Before proceeding, try turning the drum by hand

to make sure it is locked in gear. It should be locked and will

not turn.

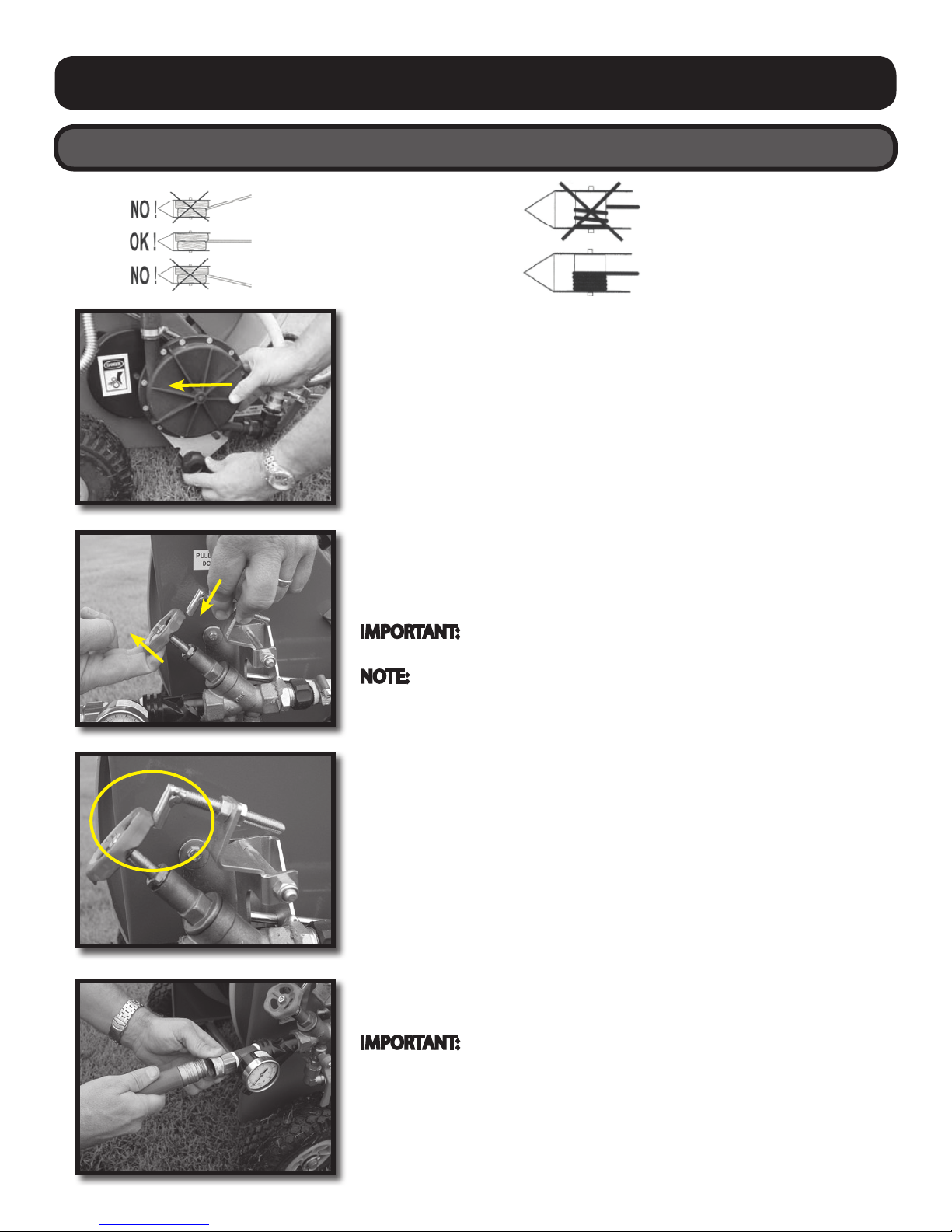

6) Open shut o valve by pulling the valve handle and latching

into the open position by swinging the valve latch down and into

position to hold valve open as shown.

IMPORTANT: PULL VALVE, DO NOT TURN!

NOTE: DO NOT PULL VALVE OPEN UNDER PRESSURE.

OPENING UNDER PRESSURE WILL DAMAGE VALVE!

VALVE SHOWN IN OPEN, LATCHED POSITION

7) Attach supply hose provided to the inlet of the machine and

lock into place as shown

IMPORTANT: MAKE SURE SUPPLY HOSE IS CLEAN

AND FREE OF FOREIGN OBJECTS THAT WOULD PLUG

THE TURBINE SYSTEM OR SHUT OFF VALVE! INLET

CONNECTION IS FITTED WITH A DEBRIS STRAINER THAT

MAY NEED TO BE CHECKED FROM TIME TO TIME AND

CLEANED IF FOREIGN OBJECTS OR MATERIAL ARE

PRESENT IN INCOMING WATER.

**Important: Always pull cart out straight and tighten loose wraps before start up!

ALWAYS PULL TUBE

OUT STRAIGHT! KEEP WRAPS TIGHT!

Start-Up Procedure/Operation Continued