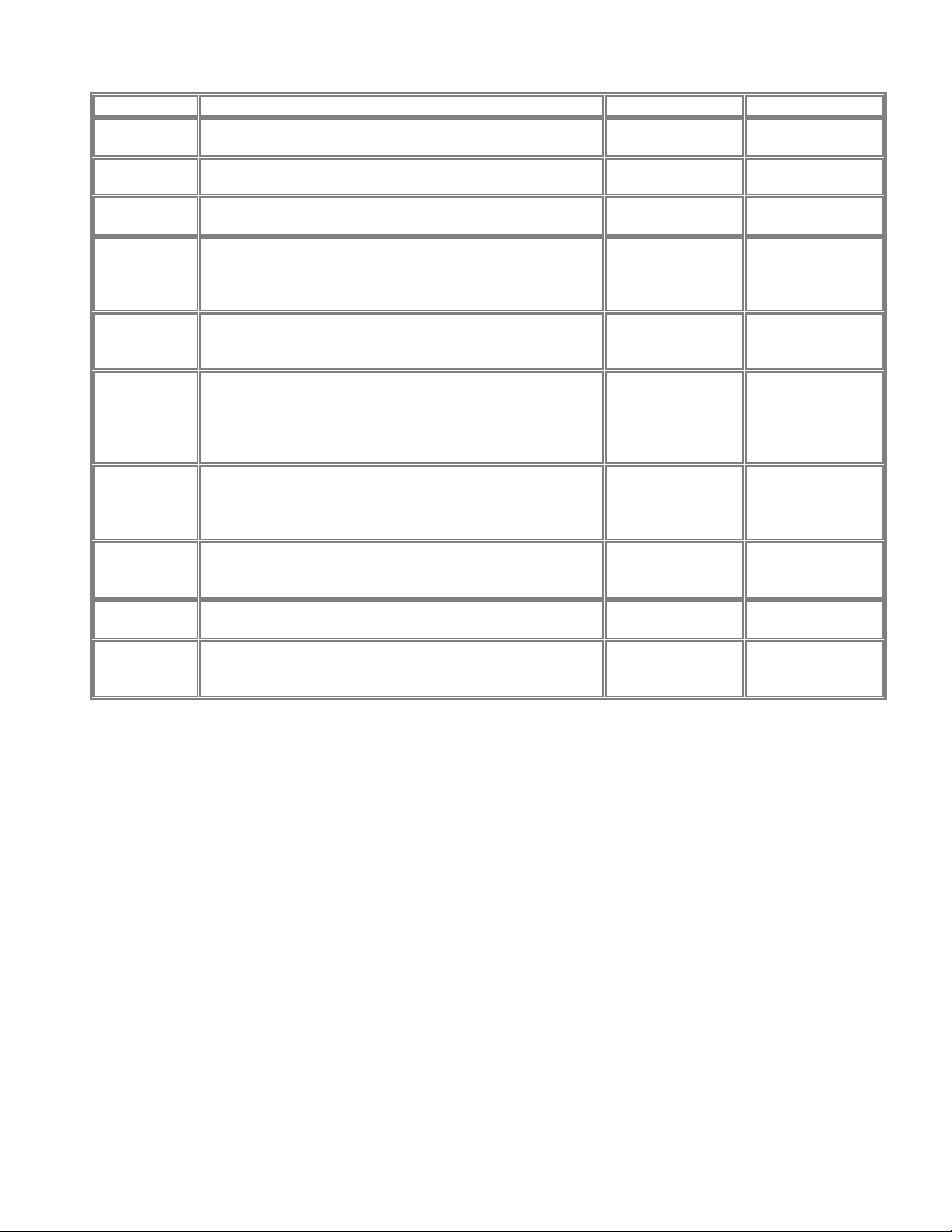

Start Temperature

Speed of acceleration/deceleration

Pump start point

Fuel start ramp

From these parameters, the readings of the engine and the position of the throttle control , the FADEC

fits the power of the pump in the following way:

First, the FADEC verifies that the pulse of control of the transmitter is correct, that is to say, is between

the limits fit by the user. If the impulse is not correct, or if impulses are not received during 0,5 seconds,

the system assumes that there is a trouble with the radio and stop the engine. During this time of delay,

the system assumes that the throttle is at idle and decelerates the engine to this power.

Once verified that the impulse is correct, the relative position of the throttle stick from the limits

programmed by the user is calculated. This calculation gives a value between 0 and 100% that can be

read in the terminal of data or the PC. This value is transformed into a value of equivalent rpm from the

values of full power pressure and idle rpm programmed by the user. If we programmed a Full power

160000 rpm, this rpm will be reached with the throttle control at 100%. With the throttle at 50%, the

equivalent pressure will be 80000 rpm. The calculated equivalent rpm is compared with the read of the

engine and the power of the pump is corrected until reaching the equality.

In case that the read rpm is superior to the required, the system lowers the power of the pump until

reaching the balance. The speed of slope is a parameter programmable by the user. In case that it is

had to raise the power of the pump, the system considers the exhaust temperature, reducing the

acceleration if the temperature approaches the maximum programmed. In case of arriving at this, the

system reduces the fuel flow until restoring the motor within its limits of operation, being able to stop it if

it can`t lower the temperature. With this system it is guaranteed that the engine accelerates in the

minimum time possible without exceeding the max. temperature, adapting itself to the variations of the

engine, room temperature, pump, etc. that could have.

Since the relation rpm/thrust in a gas turbine is quite linear, with this system the delivery of thrust of the

engine tracks linearly with the position of the throttle control, independently of the type of pump,

batteries or engine. This benefit is very useful in multiengine airplanes, since the push of the engines is

always in balance.

Aside from the protections by excess of rpm, temperature or failure of radio, the system also

incorporates two additional protections. One is the shutdown of the pump in case that the temperature

of the exhaust is lower than the minimum, protecting to the engine of flooding itself of nonburned fuel in

case of extinguishing the flame or of failure of the thermocouple. The other is the shutdown by

minimum rpm. The system stops the pump in case that the rpm reaches an inferior value than the

programmed minimum. This protection prevents to run the engine in the case of reaching an inferior

speed to the minimum.

Semi auto:

The semi-automatic start-up sequence helps you in this critical phase of the engine operation,

controlling the fuel flow and the exhaust temperature, and allow you to know and control the pump

drive power very closely.

In order to start, the user must raise the trim of the radio and let stick in idle position.

The LED of the FADEC illuminates itself, indicating the state of " ready ". Once in this position, the

operator must turn the engine with the starter motor, open the start gas, and ignite it. When the FADEC

registers a exhaust temperature higher than the programmed

start/minimum temperature, the LED begins to blink and the system begins to pump