IntelliGear PlusTM Variable Speed MD Gearmotors

MCIM15107E • Form 9708E • Printed in USA 3

Contents

1 General Information................................................................................................................................................ 4

1.1 General operating principle....................................................................................................................................... 4

1.2 Product name............................................................................................................................................................ 4

1.3 Environmental characteristics ................................................................................................................................... 4

1.4 Radio-frequency interference.................................................................................................................................... 5

1.4.1 General ..................................................................................................................................................................... 5

1.4.2 Standards (Emissions).............................................................................................................................................. 5

1.4.3 Standards (Immunity)................................................................................................................................................ 5

1.5 Description of cables and protection devices (Customer Supplied).......................................................................... 5

1.6 UL conformity ............................................................................................................................................................ 5

1.6.1 Specied mains supply ............................................................................................................................................. 5

1.6.2 Cables....................................................................................................................................................................... 5

1.6.3 Fuses ........................................................................................................................................................................ 5

1.8 Dimensions ............................................................................................................................................................... 6

2 Installation ............................................................................................................................................................... 7

2.1 General ..................................................................................................................................................................... 7

3 Connections ............................................................................................................................................................ 7

3.1 Control Terminal Blocks ............................................................................................................................................ 7

3.2 Power terminal blocks............................................................................................................................................... 7

3.2.1 Terminal block for power supply PB1 ( marked L & N )............................................................................................. 7

3.3 Wiring diagram based on standard conguration ..................................................................................................... 8

3.4 Terminal Block Assignments and MD Functionality .................................................................................................. 9

4 Commissioning ....................................................................................................................................................... 9

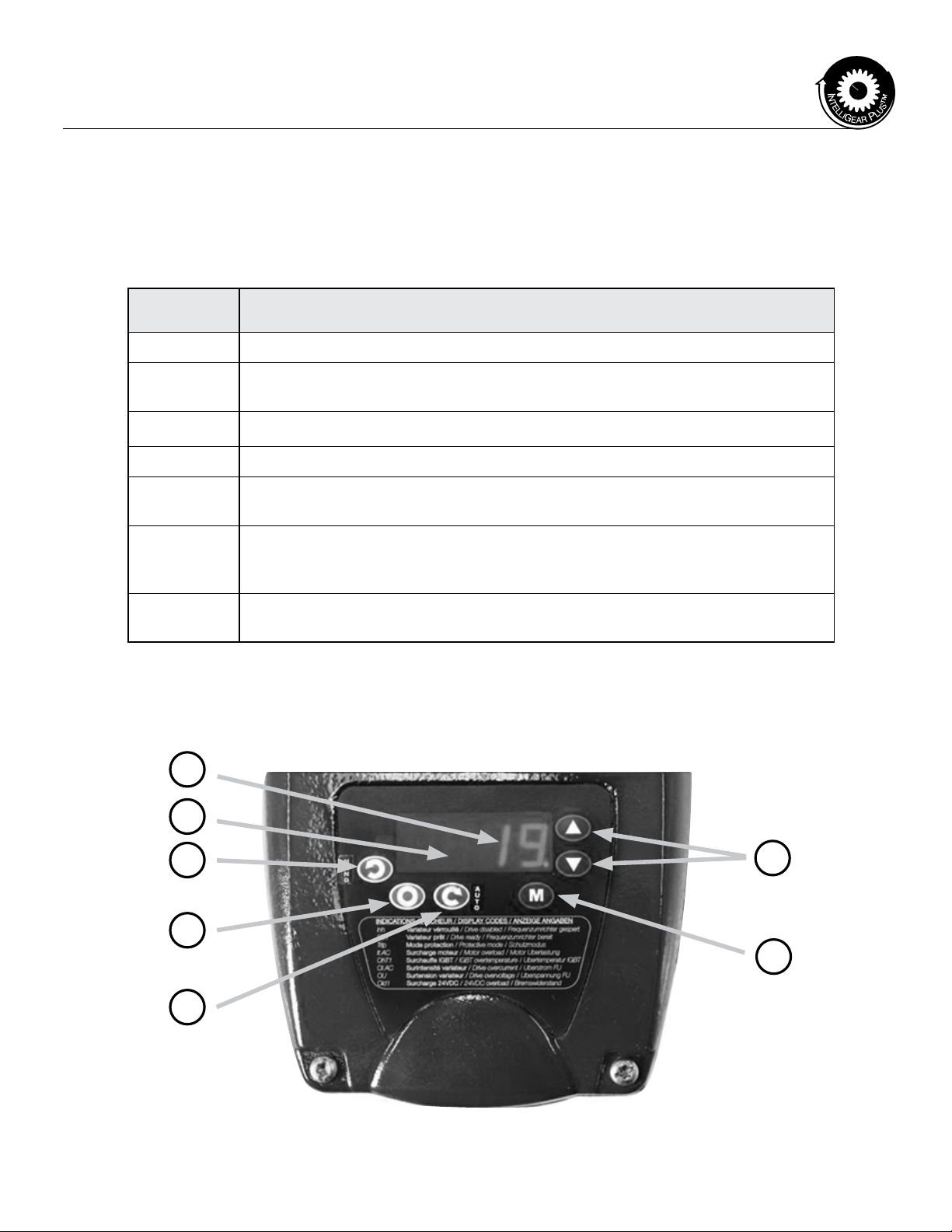

5 Operator Pad ......................................................................................................................................................... 10

5.1 Troubleshooting Guide.............................................................................................................................................11

5.2 Additional Troubleshooting.......................................................................................................................................11

5.3 Field Modications of Parameters........................................................................................................................... 12

6 Gear Lubrication ................................................................................................................................................... 13

7 Gear Parts List ...................................................................................................................................................... 14

8 Motor Parts List..................................................................................................................................................... 15