Introduction

CSE SOL G SRS1 T-E HDO Solar Pump Station is tted with a solar pump of the latest generation

that permits ow control either internally by selecting a suitable mode or externally through PWM

signal. The complicated setting of the right ow rate is not needed when the PWM signal is used, the

pump station keeps adjusting it automatically, depending on the actual solar radiation. This means

that the solar thermal system always works with the maximum possible eciency.

Thanks to a direct connection of the heating element into the special socket in the pump station, a

long power cable for the pump station and a cable ready to connect to a solar sensor, the installation

is easy and fast, no qualied electrician is needed.

2. Pump Station Description

Main Features

Application

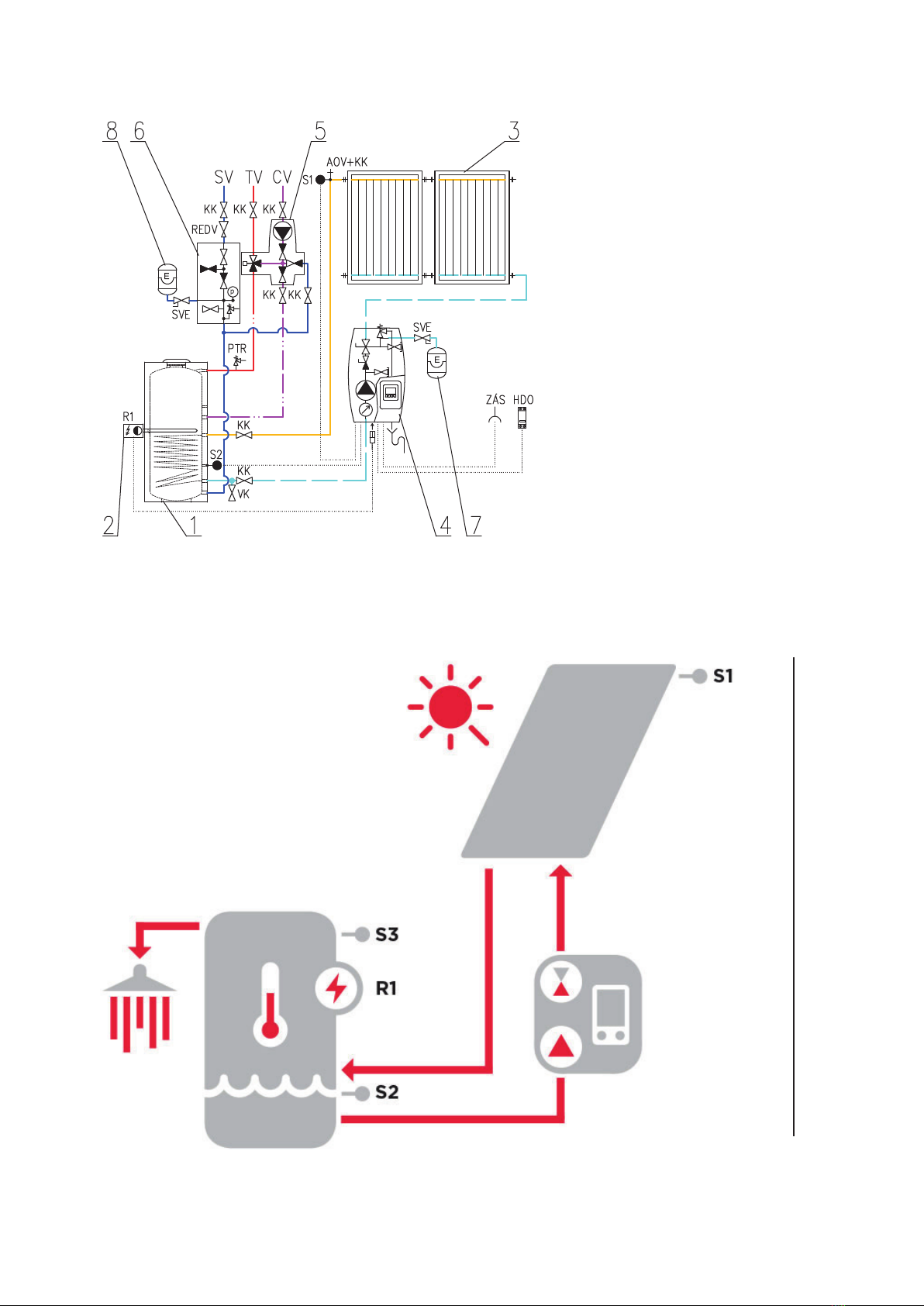

This solar pump station contains all components necessary for current and

ecient operation incl. complete electrical wiring. It is necessary to connect

only the collector temperature sensor and power cable for a heating ele-

ment via Ripple control contactor (see the following text).

An electric heating element of up to 3 kW output can be connected to the

pump station. The pump station is equipped with a special socket for this

purpose.

The heating element is powered through a separate cable that is included

in the pump station. This cable connects to the power input switched by

Ripple control. The Ripple control contactor which blocks this input during

high tari periods shall be sized to exceed safely the power output of the

installed heating element.

Neither a heating element nor a Ripple control contactor are included in

supply.

Description

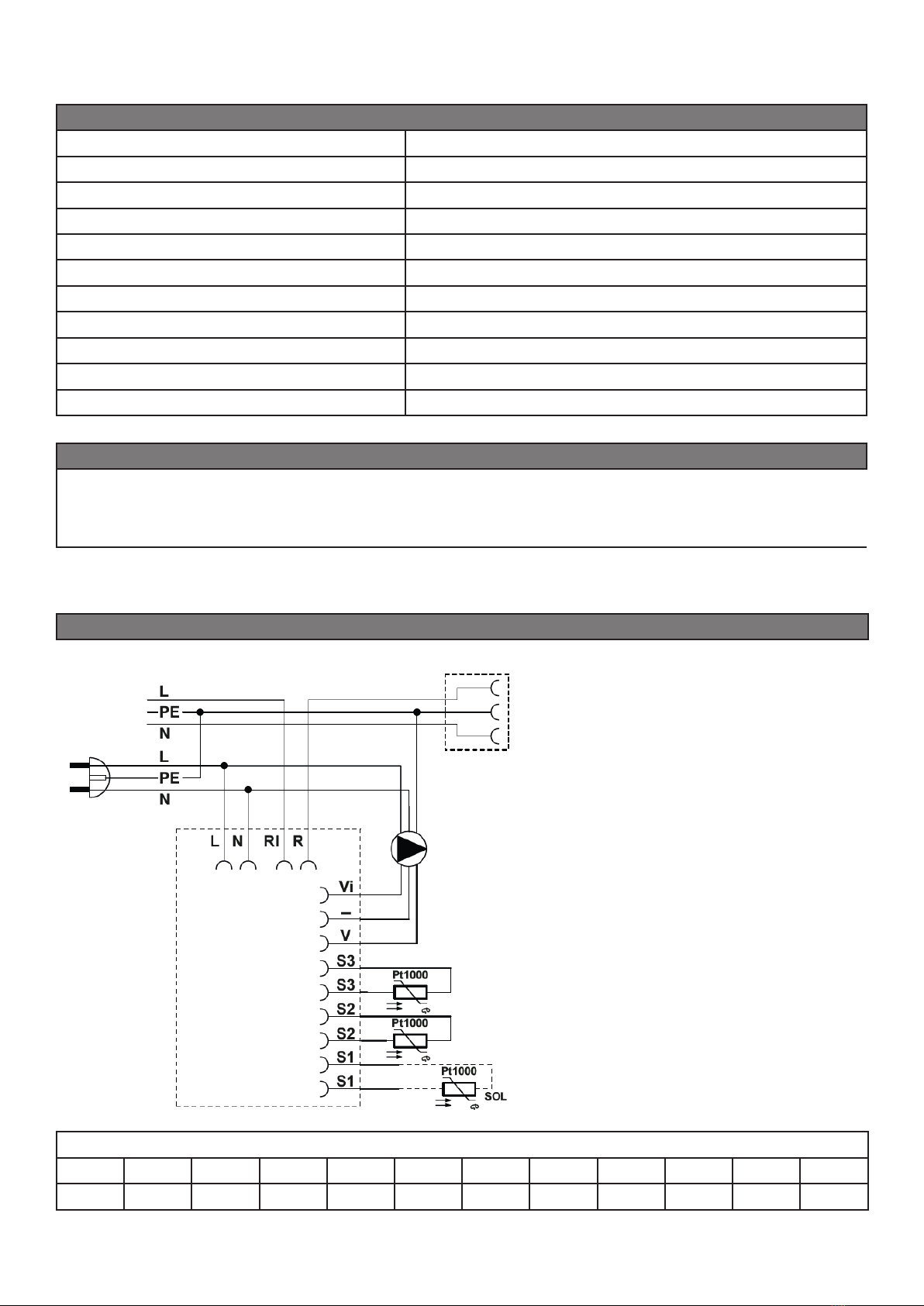

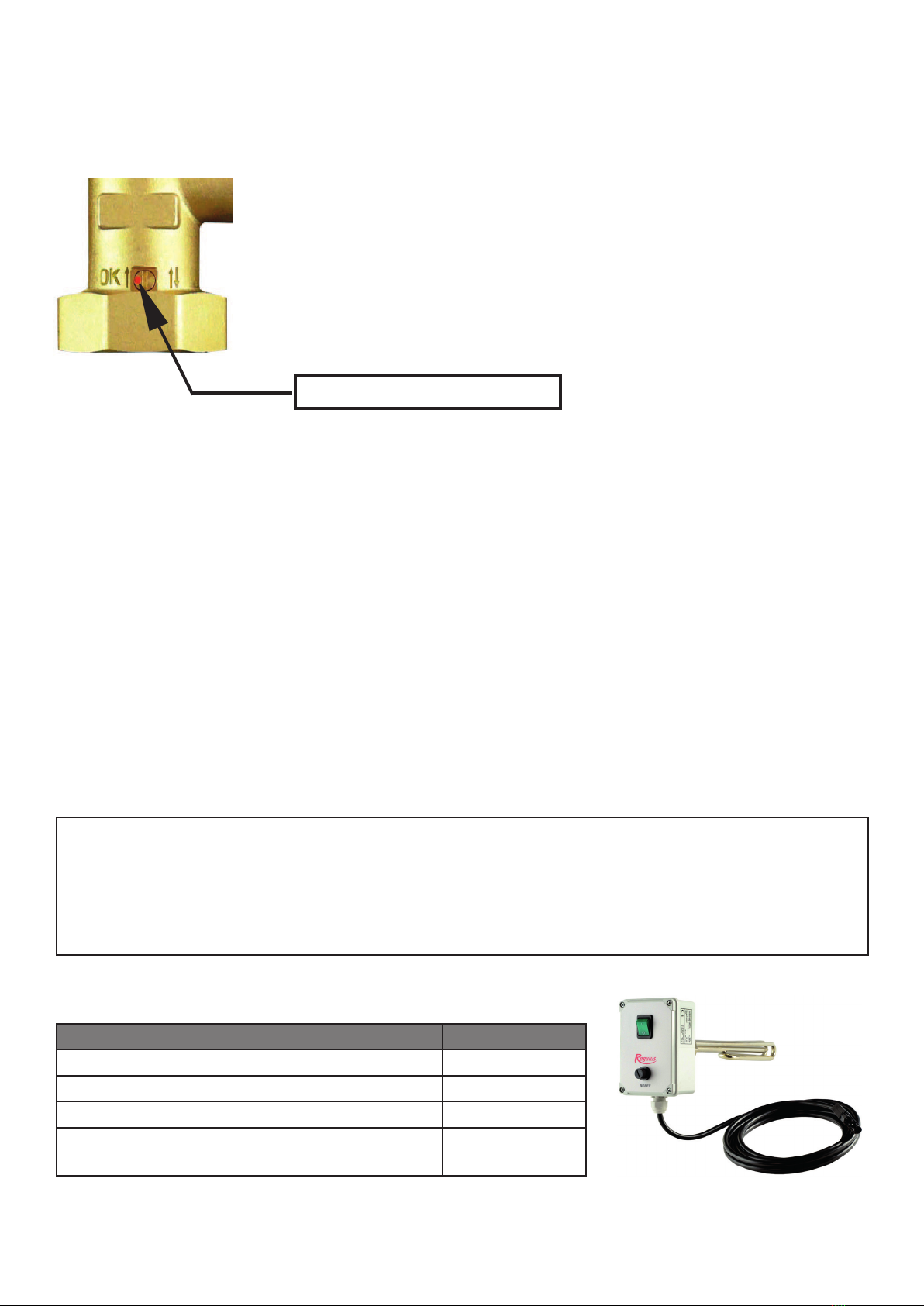

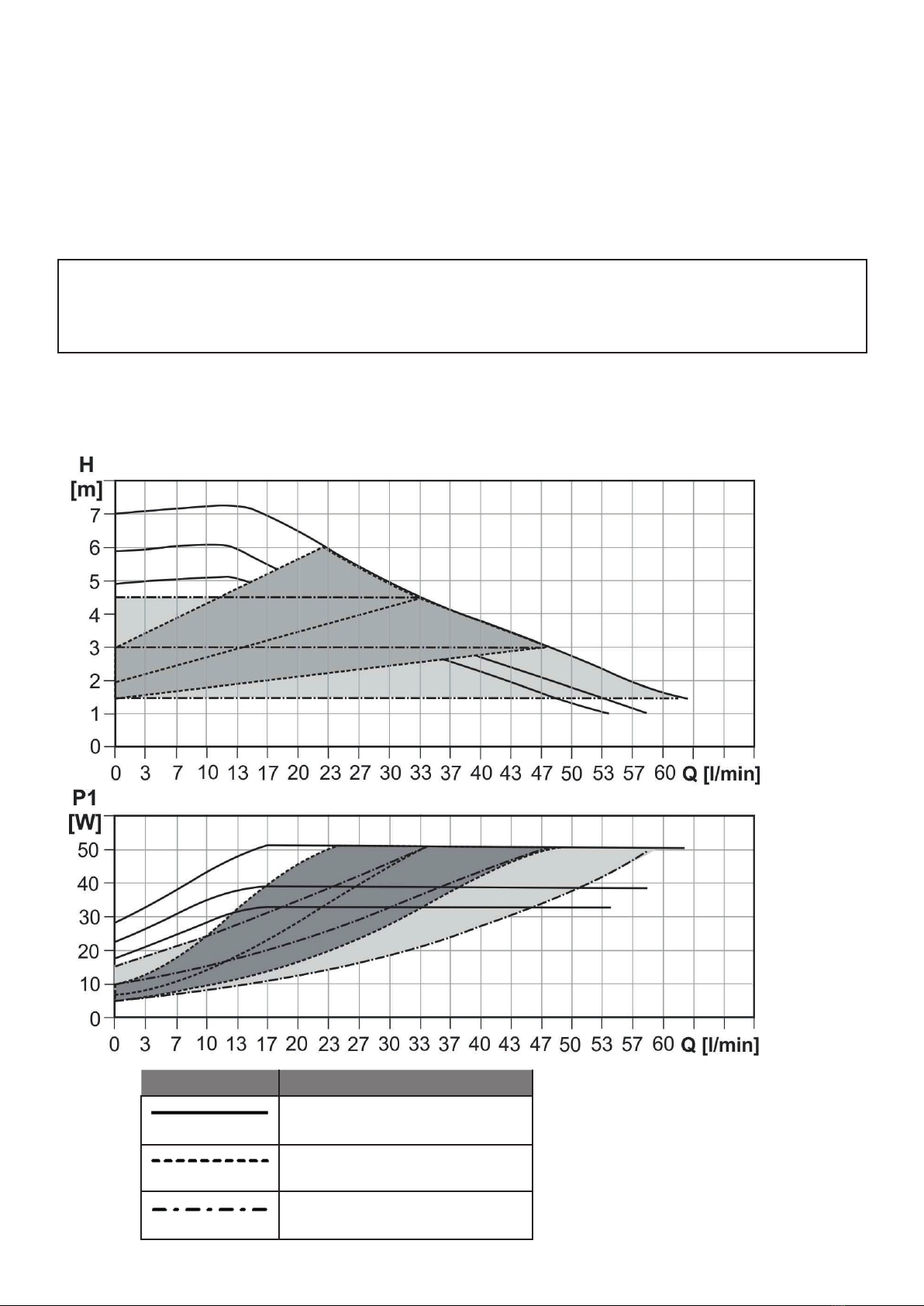

The pump station consist of a UPM3 Hybrid 25-70 pump, SRS1 T controller,

check and safety valves, 2 ball valves, pressure gauge, thermometer, el. wiring,

insulation and installation kit.

The pump station further involves:

● connection point for an expansion vessel

● safety valve outlet, incl. extension piping terminating under the pump station

for easier connection

● ball valves for lling, draining and topping up a solar thermal system

● special socket to connect a heating element of max. output of 3 KW / 230V

● two connected temperature sensors for solar consumer (4m cable)

● solar temperature sensor (2m cable, silicone insulation)

● cable for the power input switched by Ripple control (3m long, 3x1.5 mm2

cross section, black)

● 230V power cable w. el. plug (3m cable, PVC insulation)

Installation on a tank or wall

Working uid water-glycol mixture (max. 1:1)

Codes corresponding to connection sizes

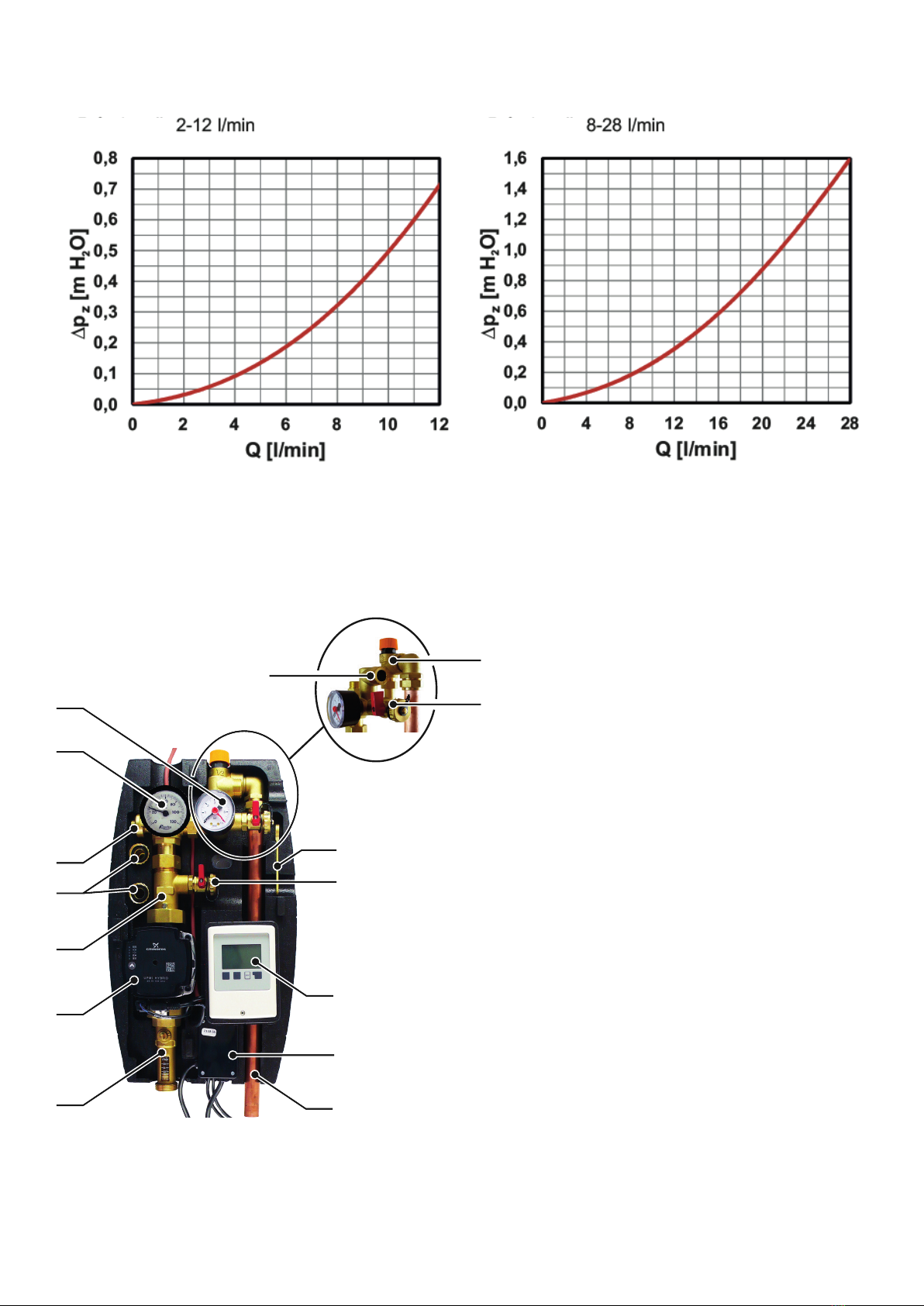

Connection G 3/4“ M G 1“ M

Flow measurement range 2-12 l/min 8-28 l/min

Code 18968 18964