10 of 24 ISSUED:11-09-07 SHEET#:202-9252-1

Español

Visite el sitio Web de Peerless en www.peerlessmounts.com Para el Servicio al cliente llame al 1-800-729-0307 ó 708-865-8870

Contenido

Lista de piezas ........................................................................................................................................................................................ 11

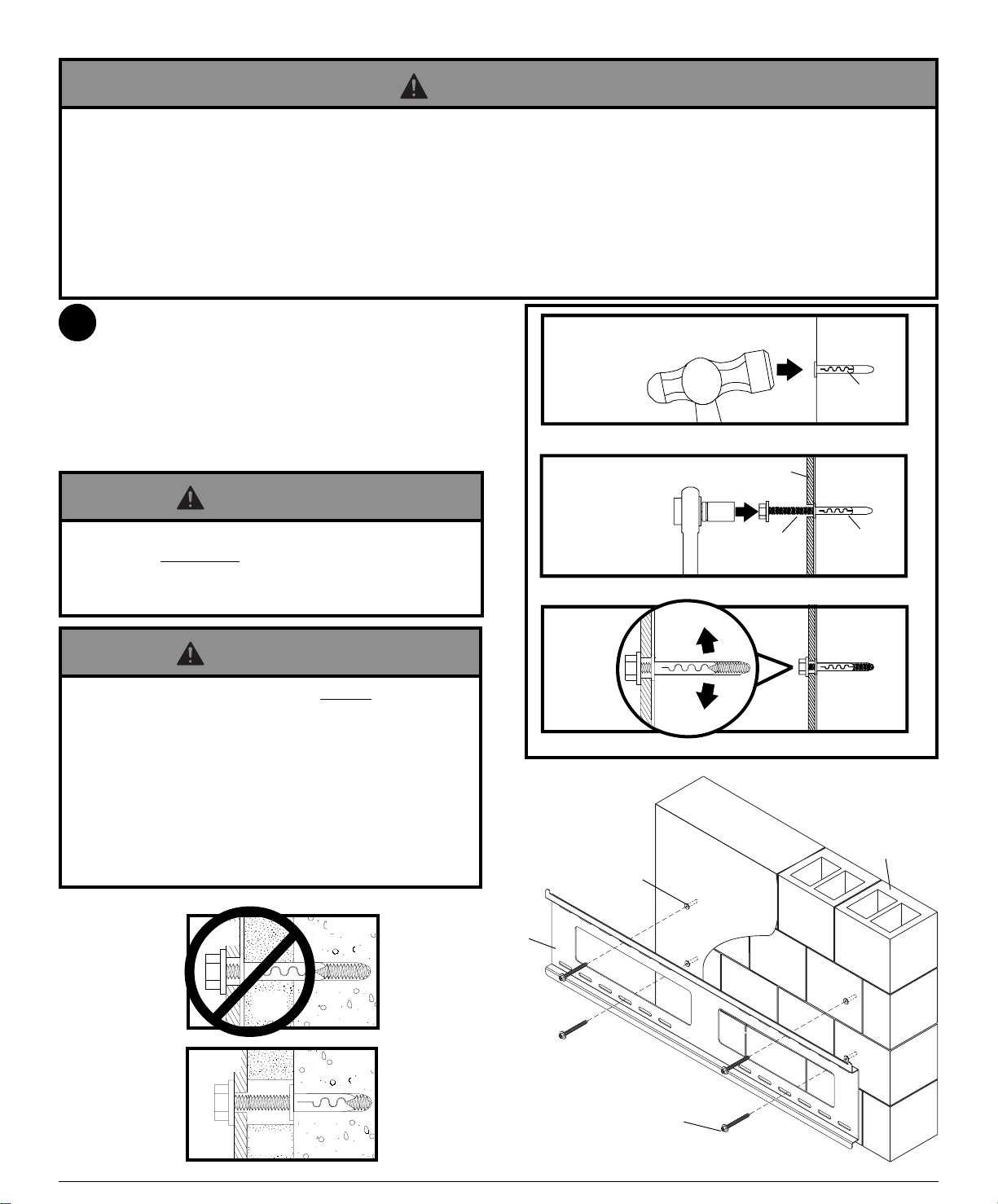

Instalación en una pared con montantes de madera dobles .............................................................................................................. 12

Instalación en una pared de concreto macizo o de bloques de hormigón de escorias .................................................................... 13

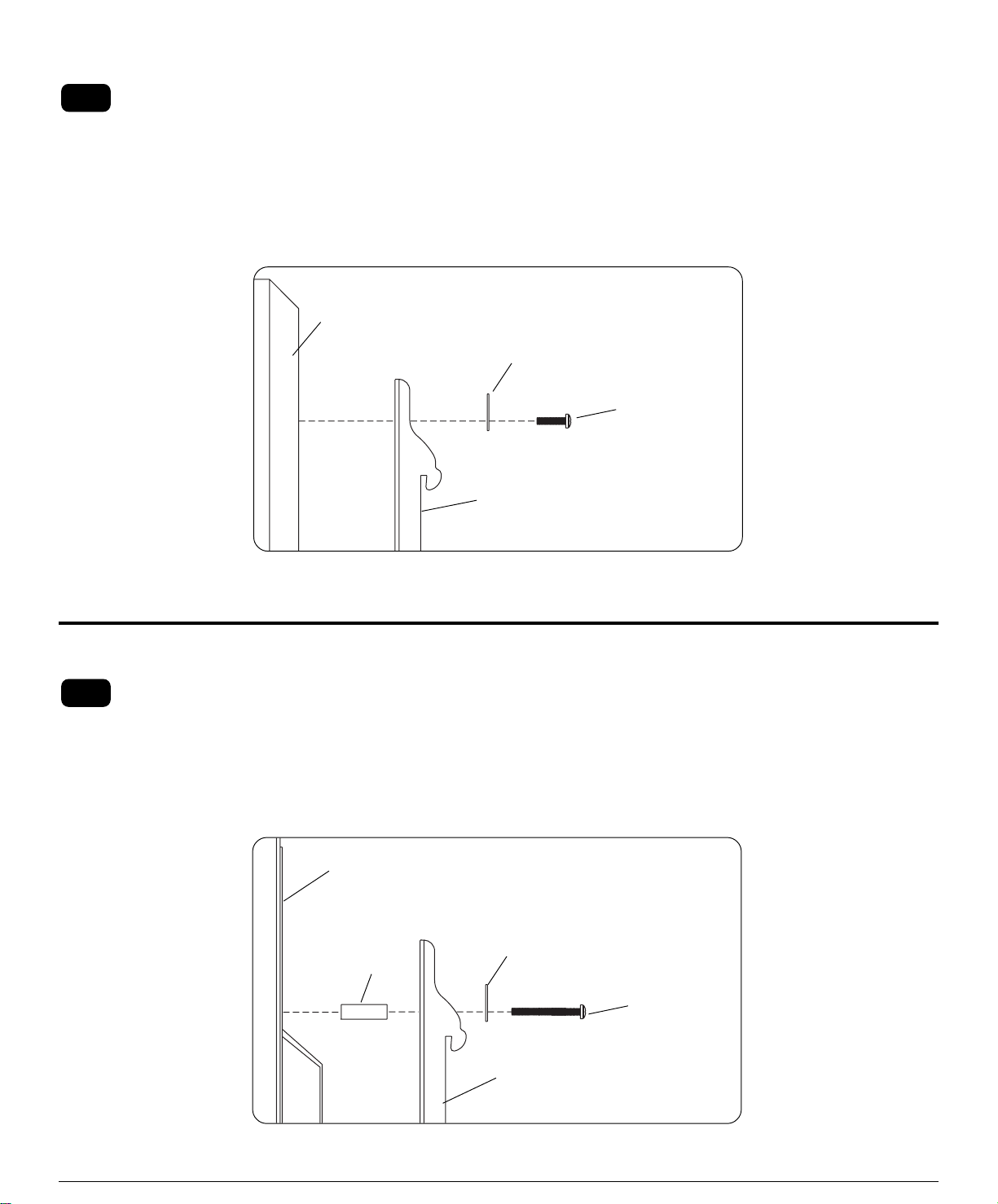

Instalación de los soportes adaptadores ............................................................................................................................................. 14

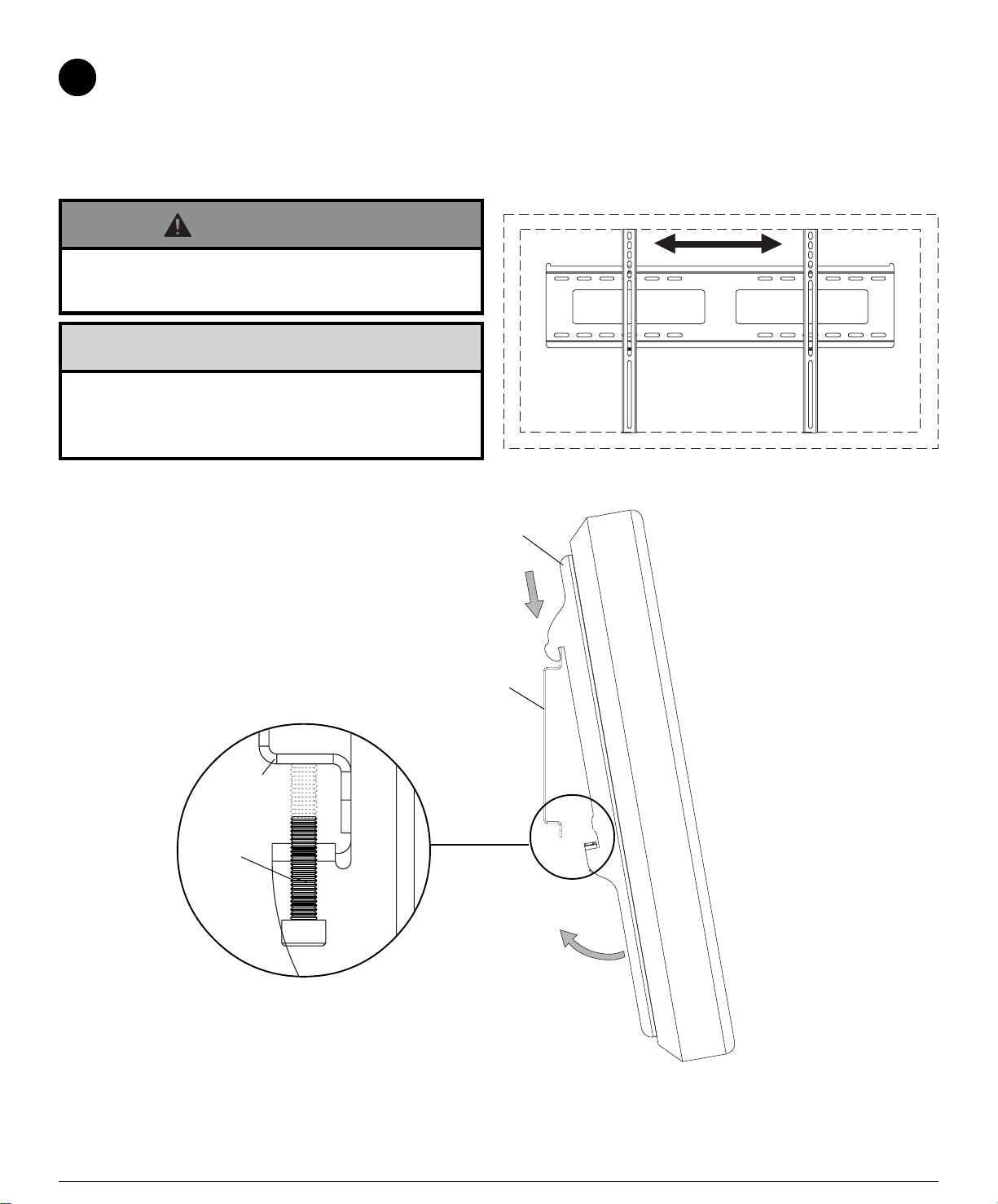

Instalación de la pantalla plana en la placa de apoyo ......................................................................................................................... 16

Para atención al cliente, llame al (800) 729-0307 ó (708) 865-8870.

Accessories

•Repisa ParamountTM - PCS200 para

componentes de A/V

•Juego de accesorios de piezas para la fijación en

montantes de metal - ACC415 (El montante de

metal no ha sido evaluado por UL)

Herramientas necesarias para el montaje

•localizador de montantes (se recomienda usar el de “borde a borde”)

•destornillador phillips

•taladro

•broca de 1/4" para pared de concreto y de bloques de hormigón de

escorias

•broca de 1/2" para pared con montantes de metal

•broca de 5/32" para pared con montantes de metal o madera

•nivel

• No comience a instalar su producto de Peerless hasta haber leído y entendido las instrucciones y las advertencias

contenidas en la Hoja de Instalación. Si tiene alguna pregunta acerca de cualquiera de las instrucciones o las

advertencias,porfavor,llameaServicio al ClientedePeerlessal1-800-865-2112.

• Esteproductosólodebeserinstaladoporunapersonaquetengauna aptitud mecánica, que tenga experiencia en

construcción básica de edificios y que entienda estas instrucciones en su totalidad.

• Asegúrese de que la superficie de apoyo sostendrá, con seguridad, la carga combinada del equipo y todos los

fijadoresycomponentes.

• Nuncasobrepaselacapacidad máxima desoportarcarga aceptada porUnderwritersLaboratories.(Vea lapágina9).

• Si va a instalar el producto en una pared con montantes de madera, asegúrese de que los tornillos de montaje estén

anclados en el centro de los montantes. Se recomienda utilizar un localizador de montantes de “borde a borde”.

• Siempre cuente con la ayuda de un asistente o utilice un equipo mecánico de izar para levantar y colocar el equipo

conmásseguridad.

• Apriete los tornillos con firmeza, pero no en exceso.Apretarlos en exceso puede dañar los artículos y puede

disminuirsignificativamentesufuerzade fijación.

• Este producto fue diseñado con la intención de que se instale en las superficies de apoyo marcadas abajo con los

accesorios de instalación incluidos en este producto como se especifica en la hoja de instalación. Para instalar este

productoenotrasuperficiedeapoyo,llame a Servicio al ClientedePeerlessal1-800-865-2112.

• Esteproductofuediseñadoparaserinstaladoenparedesconlasiguienteconstrucciónsolamente:

CONSTRUCCIÓNDELAPARED ACCESORIOSADICIONALES NECESARIOS

xMontantedemadera Ninguno

xVigademadera Ninguno

xConcretomacizo Ninguno

xBloquedehormigóndeescorias Ninguno

Montantedemetal No lo instale excepto con el juego de accesorios de Peerless para

montantes de metal.

Llame a Servicio al Cliente para pedir el juego de accesorios de

Peerless para montantes de metal.

Ladrillo ComuníqueseconServicioal Cliente.

¿Otrasuperficieonoestáseguro? Comuníquesecon Servicio alCliente.

ADVERTENCIA

Nota: Lea la hoja de instrucciones completa antes de comenzar la instalación y el ensamblaje.