Validity

This information is valid globally.

Check for the latest version

For safety and the correct use of our products, please

check the latest version of our technical information.

To get information on the latest version please contact

REHAU or visit www.REHAU.com/ti.

Navigation

At the beginning of this manual you will find a detailed

table of contents with titles to the related pages.

Pictograms and logos

Safety information

Legal information

Important information

Benefits

Information online

Colour varies

Colour black

Colour grey

Colour white

Stainless steel

Anodised aluminium

Package quantities

Seal with silicone

Soft face mallet (non-rebound)

Distribution of information

Please make sure that your customers (e.g. end

consumers) are informed about the correct use and

maintenance of this product. The use and maintenance

information needs to be made available to the end

consumer by you or your customer.

Correct application

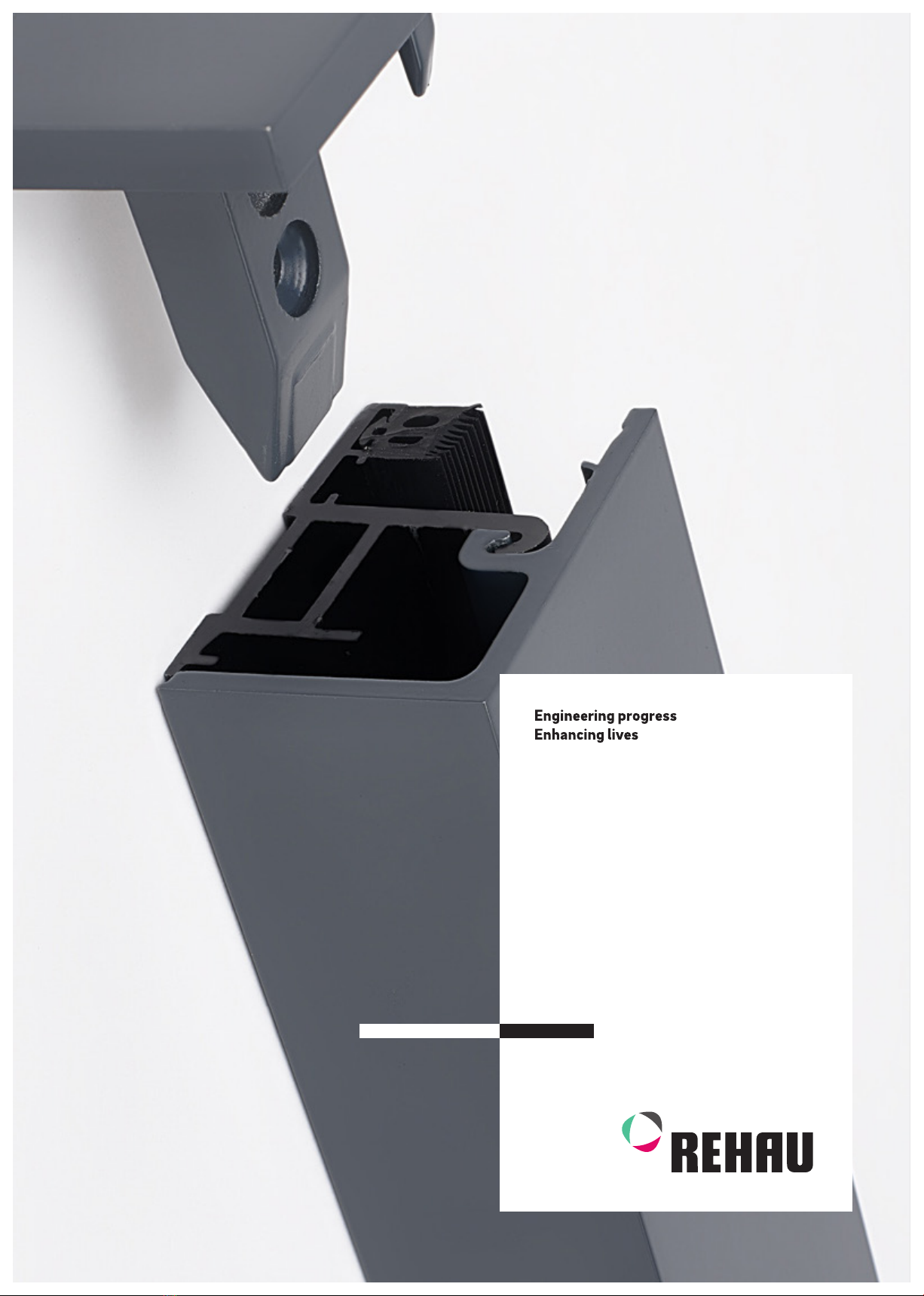

The SKYFORCE Juliet balcony system can only be

specified, fabricated and installed as directed in this

technical documentation. Any deviation is prohibited.

Suitability of materials

The current technical documentation needs to be

followed for fabrication, installation and use of

SKYFORCE. Our technical documentation is based on

testing and experience at the time of print. The transfer

of this document does not entail any warranty of

properties for the listed products. No warranty can be

derived from this document. The information contained

within this document does not exonerate any user/buyer

from checking the suitability of the product for the

specific application in question.

Maintenance and care

In order to ensure the functionality of SKYFORCE over

an extended period of time it is necessary to maintain it

regularly. SKYFORCE is also used as fall protection,

because of this all components need to be kept in proper

condition. Any occurring damages need to be assessed

by the installation company or the fabricator and

replaced if necessary.

Therefore the following maintenance should be carried

out at least once a year:

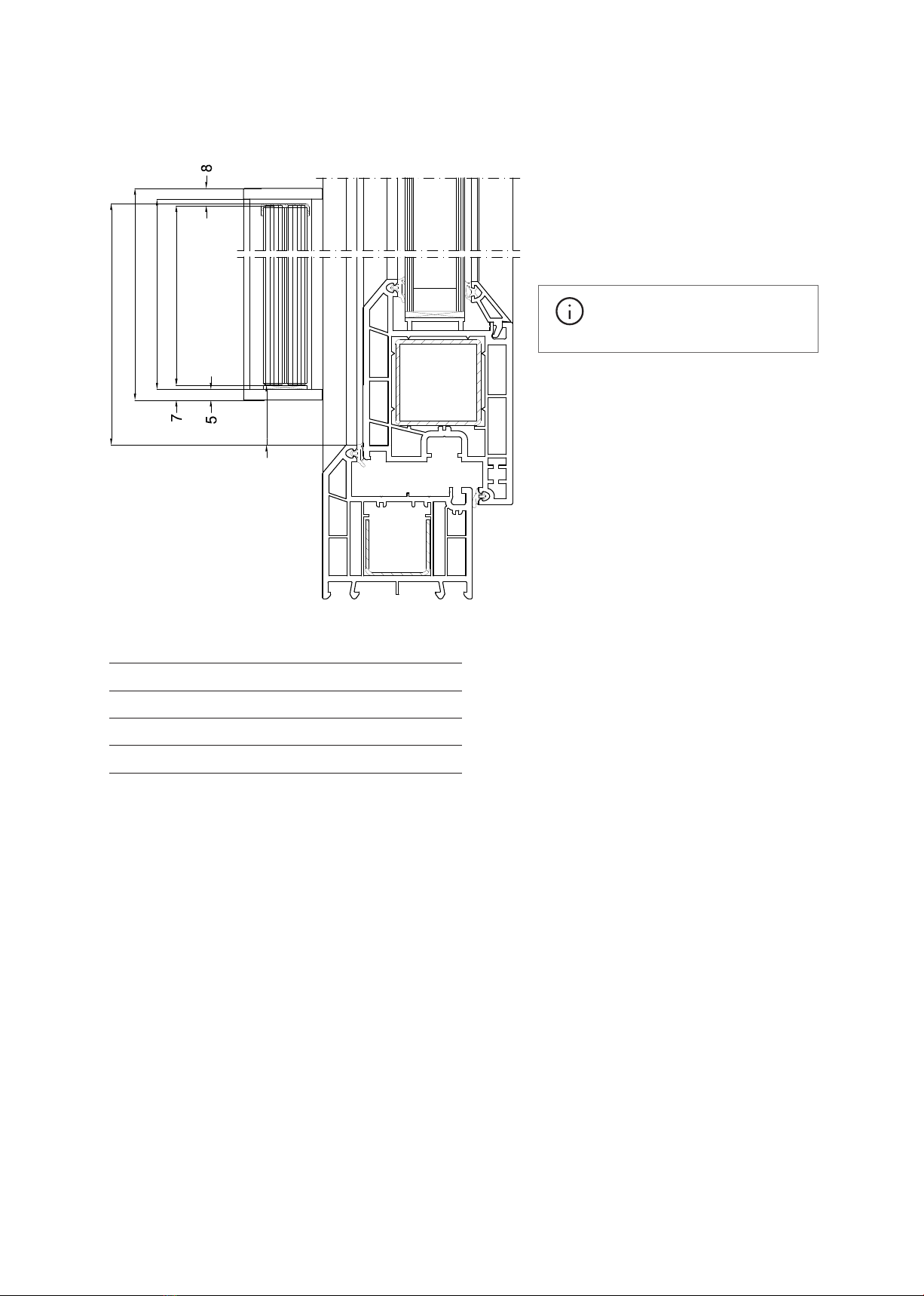

• Check whether there are visible or noticeable

damages to any of the gaskets, profiles, windows or

fasteners of the french balcony or window.

• If there is damage to the glass, a replacement is

necessary.

• Check the surface and clean if necessary.

For these reasons REHAU recommends to share this

information about maintenance and care with the end

consumer.

01 General and safety information

3

Information / Safety Instructions