Table of contents

2 / 44 TARAtec 9/10

Table of contents

1Information about these operating instructions..................................4

1.1 Symbols and displays ................................................................4

1.2 Associated documents...............................................................5

2Information on this product..................................................................6

2.1 Product description ....................................................................6

2.2 Scope of supply.........................................................................8

2.3 Product overview .......................................................................9

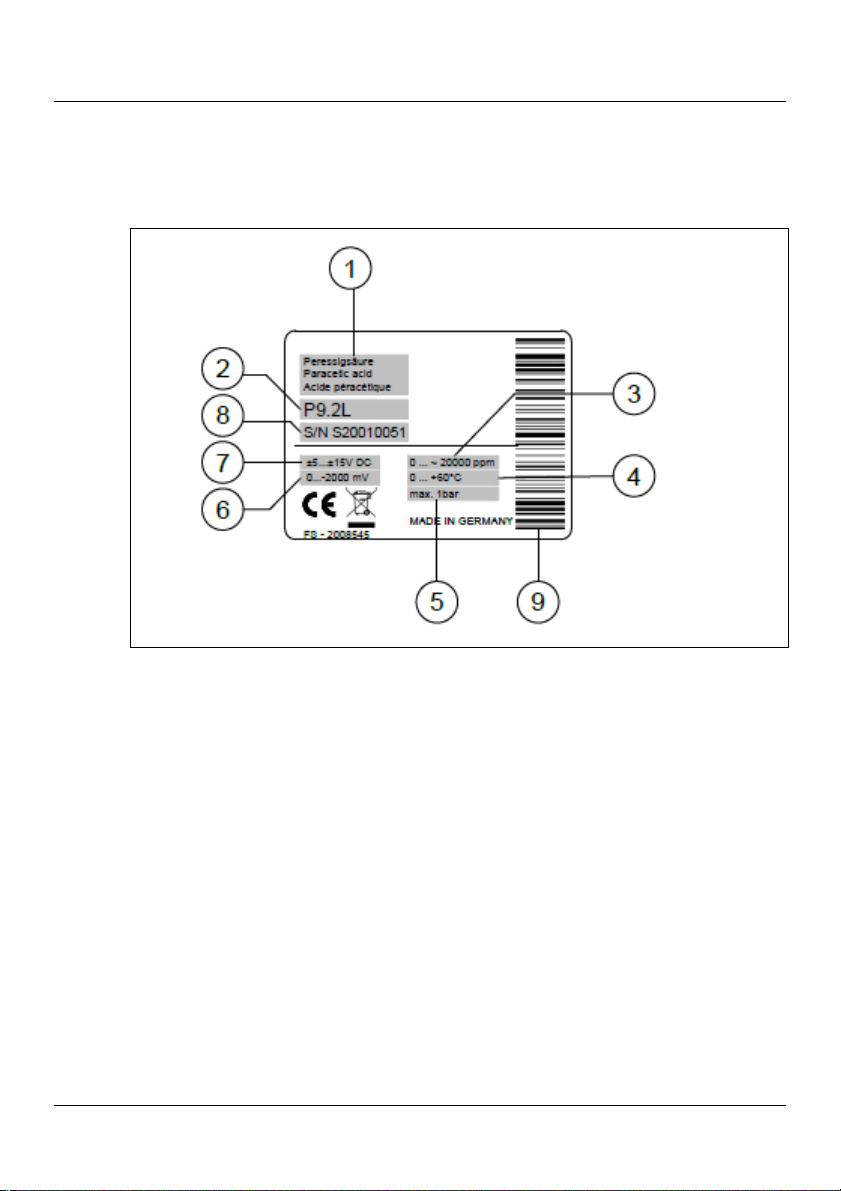

2.4 Name plate..............................................................................10

3Safety ..................................................................................................11

3.1 Use for the intended purpose...................................................11

3.2 Use other than for the intended purpose...................................11

3.3 Personal qualifications .............................................................12

3.4 Rebuilding and modifications....................................................12

3.5 Residual risks ..........................................................................12

4Commissioning...................................................................................16

4.1 Installation requirements..........................................................16

4.2 Preparation of the sensors.......................................................16

4.3 Insertion into the flow chamber.................................................19

4.4 Electrical connection................................................................20

4.5 Initial calibration.......................................................................22

5Calibration...........................................................................................23

6Removal ..............................................................................................25