TABLE OF CONTENTS

OVERVIEW..................................................................................... 3

INSTALLATION TIPS...................................................................... 3

Tuning Note.................................................................................. 4

TOOLS ............................................................................................ 4

INCLUDED PARTS ......................................................................... 5

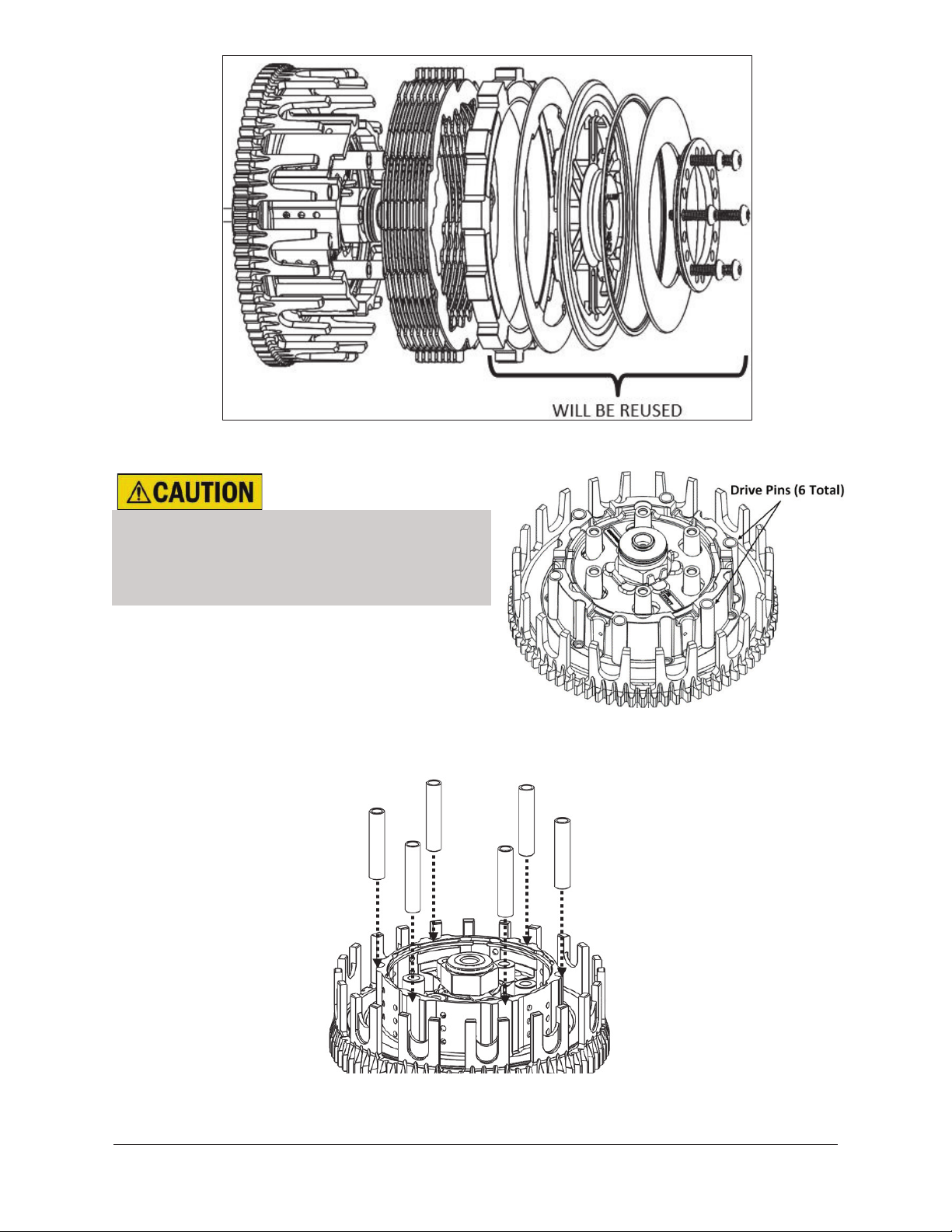

DISASSEMBLE THE CLUTCH ....................................................... 6

INSPECT THE DAMPERS.............................................................. 8

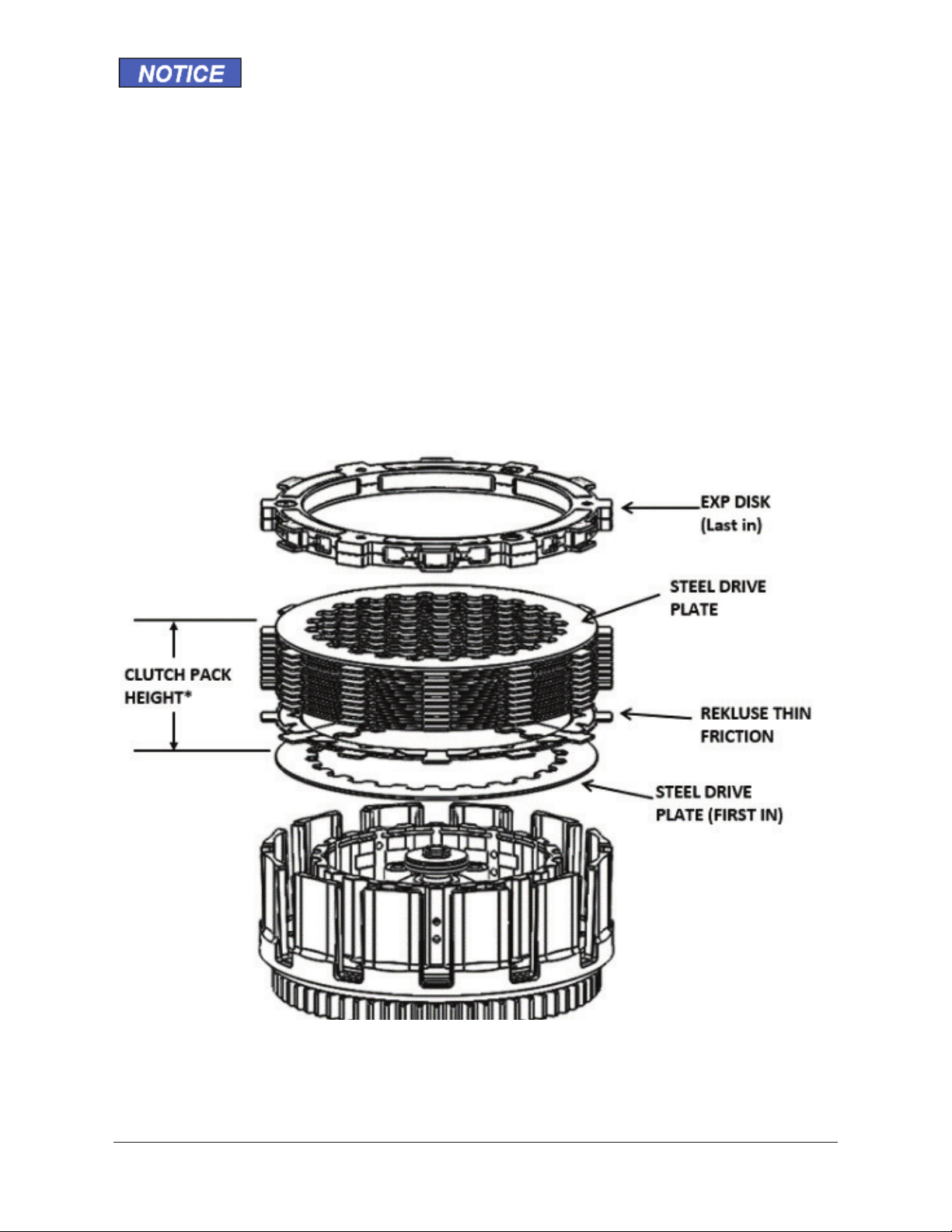

CLUTCH PACK INSTALLATION..................................................... 8

PRESSURE PLATE INSTALLATION............................................ 11

SET THE INSTALLED GAP AND VERIFY BY CHECKING FREE

PLAY GAIN ................................................................................... 15

Step 1: Find the starting point..................................................... 16

Step 2: Learn how to check Free Play Gain ............................... 17

Two Ways to Check for Free Play Gain ..................................... 19

The Rubber Band Method .......................................................... 19

The Hand Method....................................................................... 22

Step 3: Break-in the new clutch.................................................. 24

Step 4: Adjust the installed gap and Recheck Free Play Gain ... 26

FREE PLAY GAIN ADJUSTMENTS ............................................. 28

MAINTENANCE ............................................................................ 29

Disk inspection examples........................................................... 31

TROUBLESHOOTING .................................................................. 32

Performance issues.................................................................... 32

Clutch noise................................................................................ 32

EXP TUNING OPTIONS ............................................................... 32

Changing the springs ................................................................. 33

Configuration chart ..................................................................... 35

BUMP-STARTING THE BIKE ....................................................... 35

NEED ADDITIONAL HELP? ......................................................... 36