TABLE OF CONTENTS

OVERVIEW ...........................................................................3

INSTALLATION TIPS ............................................................3

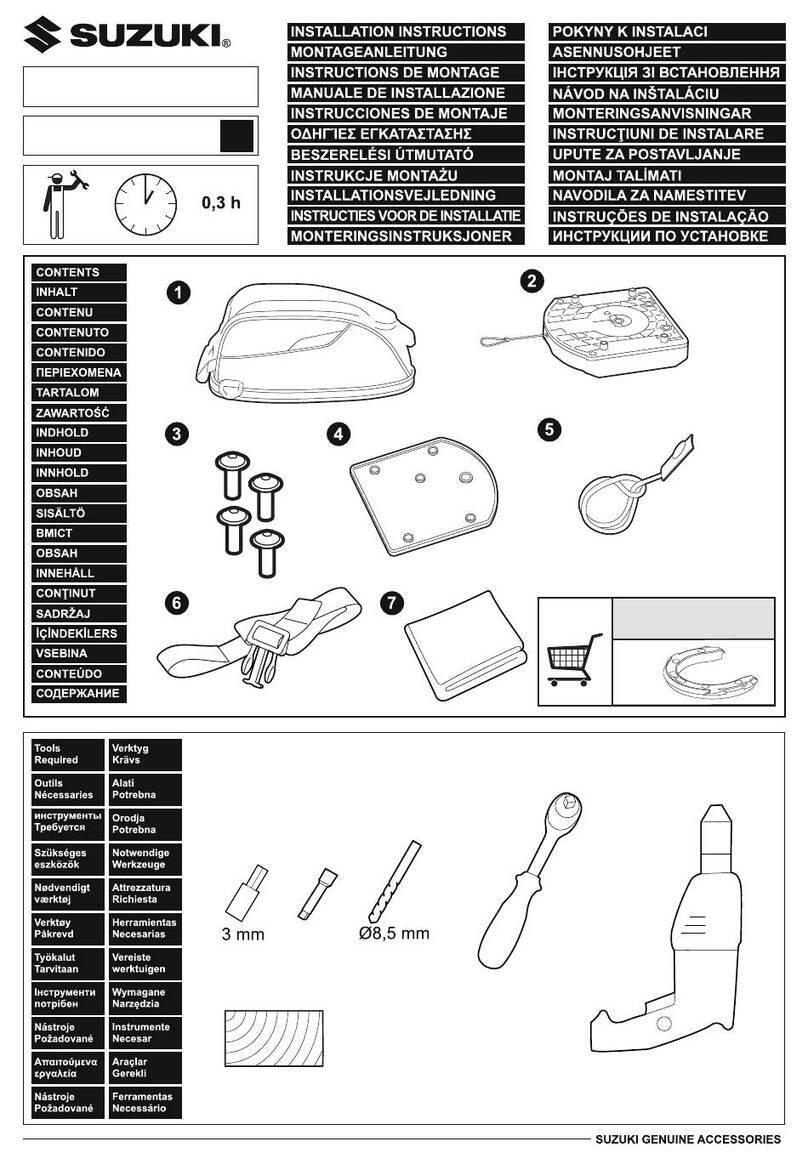

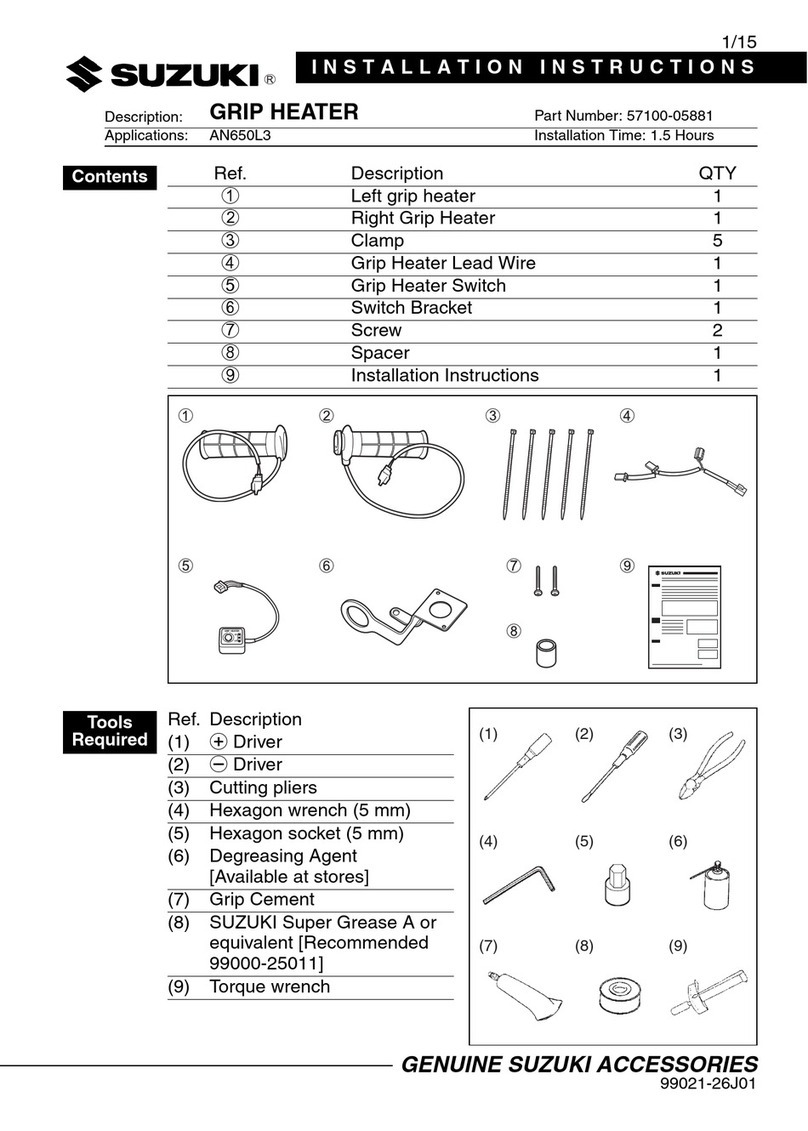

TOOLS NEEDED...................................................................4

INCLUDED PARTS ...............................................................5

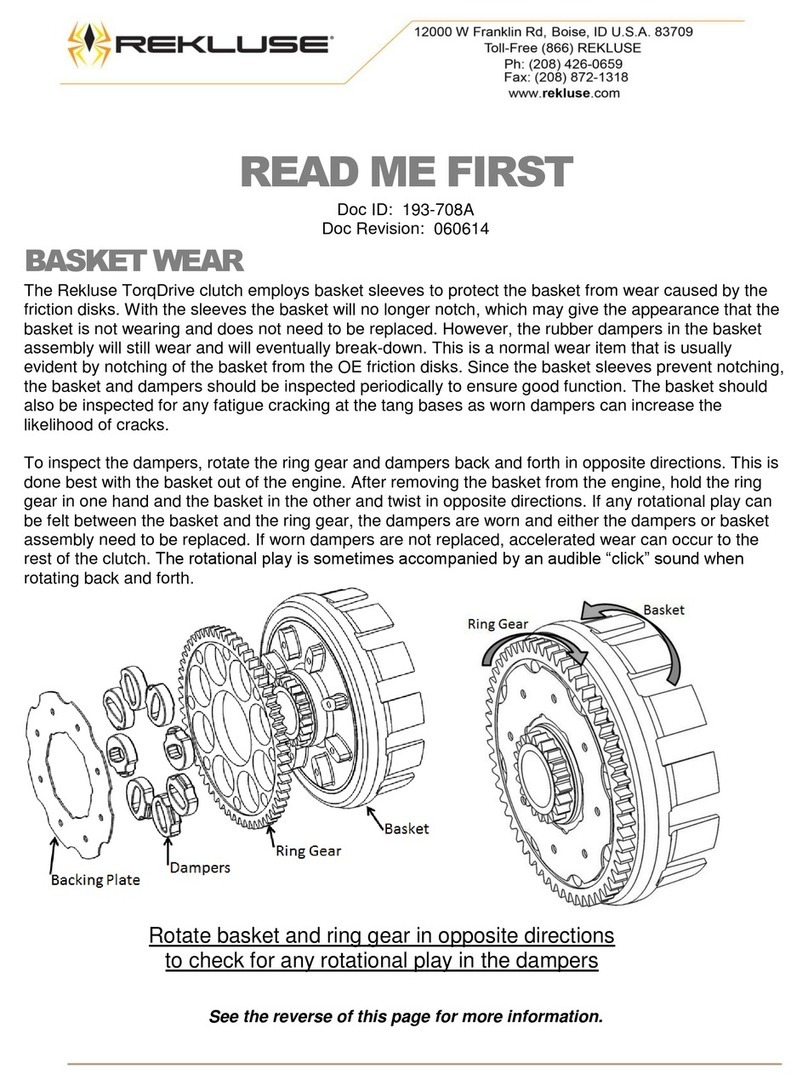

DISASSEMBLE THE CLUTCH .............................................6

CLUTCH PACK INSTALLATION.........................................10

Notes for installation........................................................10

Clutch pack......................................................................10

PRESSURE PLATE INSTALLATION..................................13

PRIMARY COVER INSTALLATION....................................15

SET THE INSTALLED GAP ................................................18

CHECK FREE PLAY GAIN..................................................19

Learn how to check Free Play Gain ................................19

Two Ways to Check for Free Play Gain ..........................21

The Rubber Band Method ...................................................21

The Hand Method................................................................24

Adjust the Installed Gap.......................................................25

BREAK IN THE NEW CLUTCH...........................................26

EXP TUNING OPTIONS......................................................28

Changing the EXP springs ..................................................29

SHIFTING AND OPERATION .............................................30

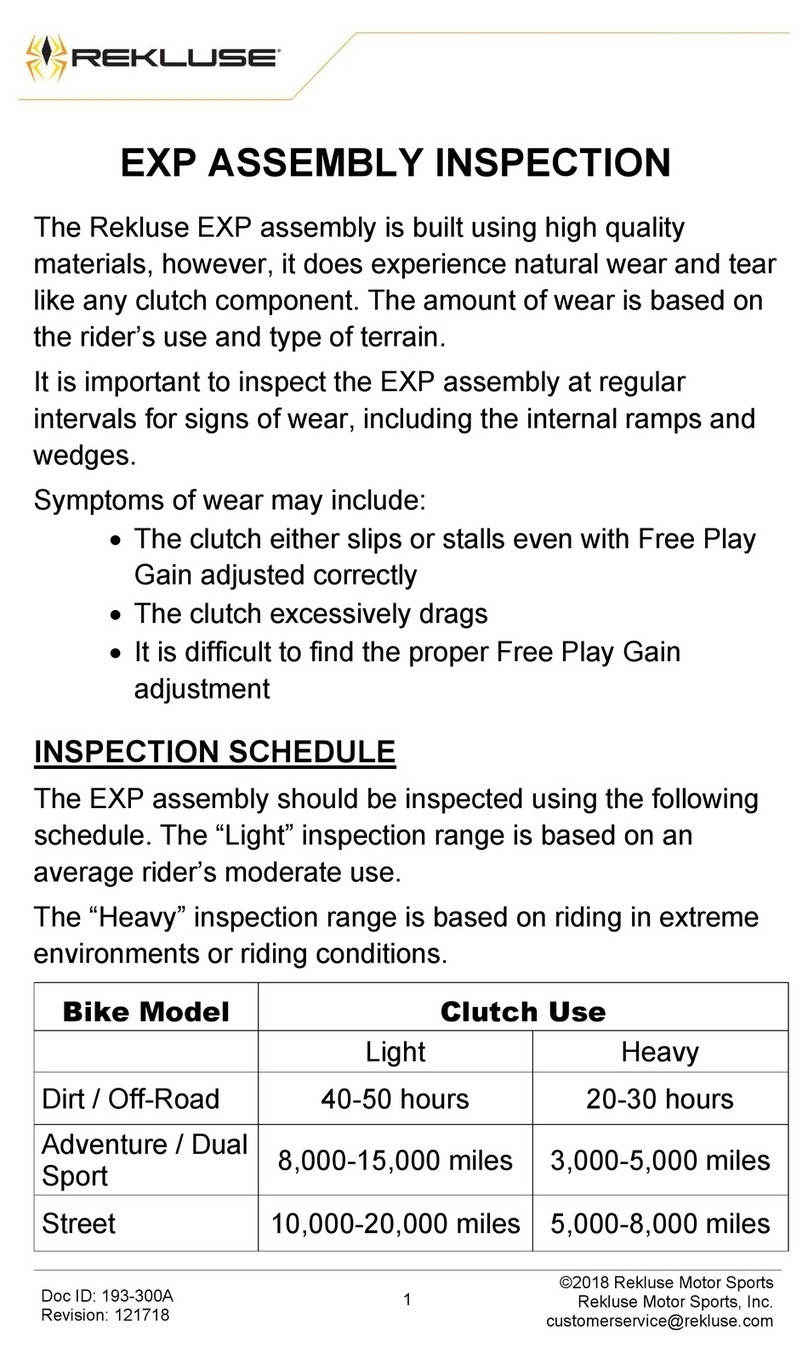

MAINTENANCE...................................................................32

Disk inspection examples................................................32

TROUBLESHOOTING.........................................................34

NEED ADDITIONAL HELP?................................................35