Table of Contents

OVERVIEW ...................................................................................2

INSTALLATION TIPS ....................................................................2

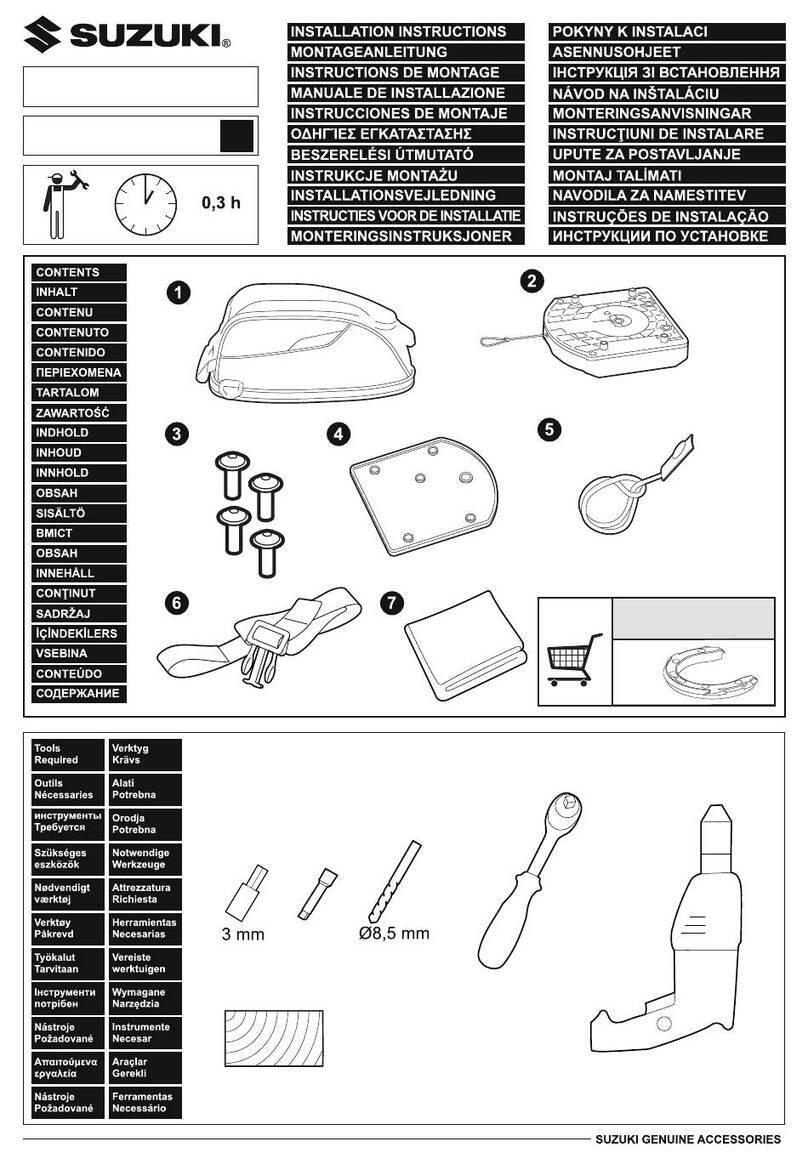

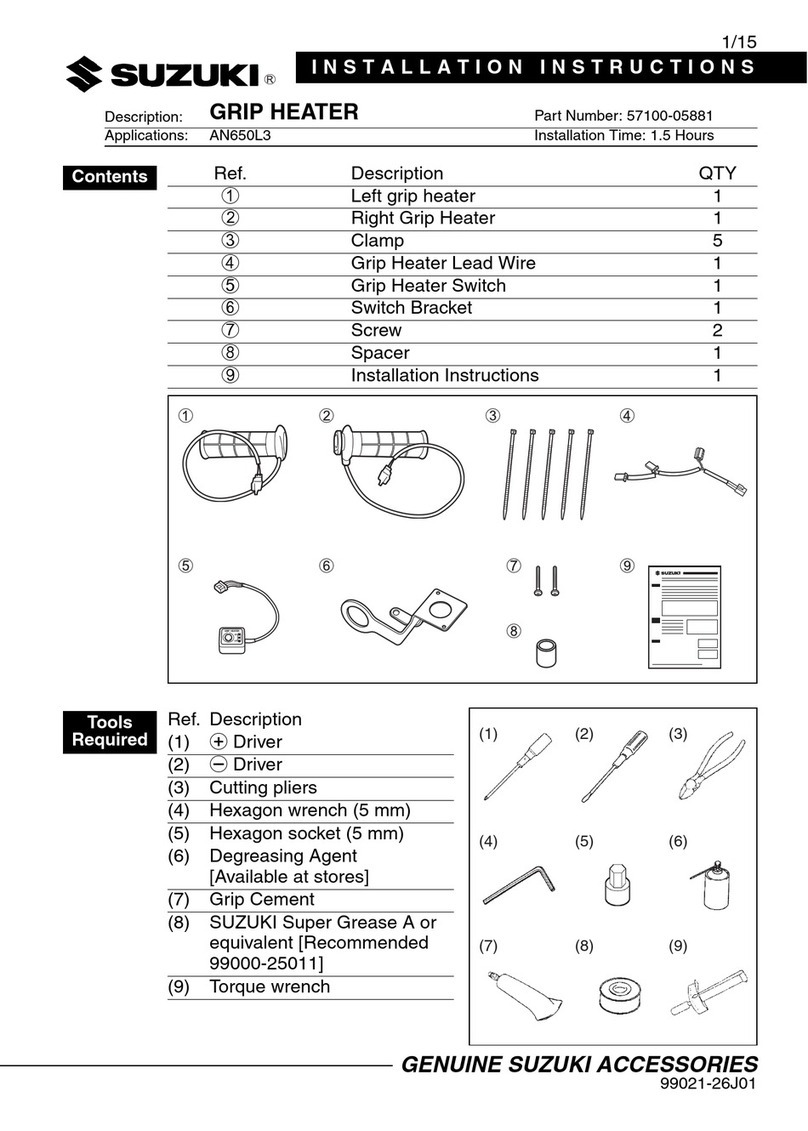

TOOLS...........................................................................................3

INCLUDED PARTS .......................................................................4

DISASSEMBLE CLUTCH..............................................................5

INSTALL THE HUB .......................................................................9

INSTALL THE CLUTCH PACK ...................................................11

INSTALL THE CLUTCH COVER ................................................15

BREAK IN ....................................................................................15

MAINTENANCE...........................................................................15

NEED ADDITIONAL HELP?........................................................16

OVERVIEW

This kit replaces OE (Original Equipment) or “stock” core clutch

components including the center clutch hub and pressure plate

with high-quality billet components designed for optimal

performance specific to your bike.

·All OE steel drive plates & friction disks will be replaced with

ones provided by Rekluse.

INSTALLATION TIPS

·Read the separate included Safety

Information document before

operating the vehicle with the

product installed.

·Read this entire document before performing any steps.

·If you install this product for a customer or another person,

instruct them to read the Safety Information document and

the Installation and User Guide before operating the vehicle

with the product.

·Protect eyes and skin –wear safety glasses and work gloves.