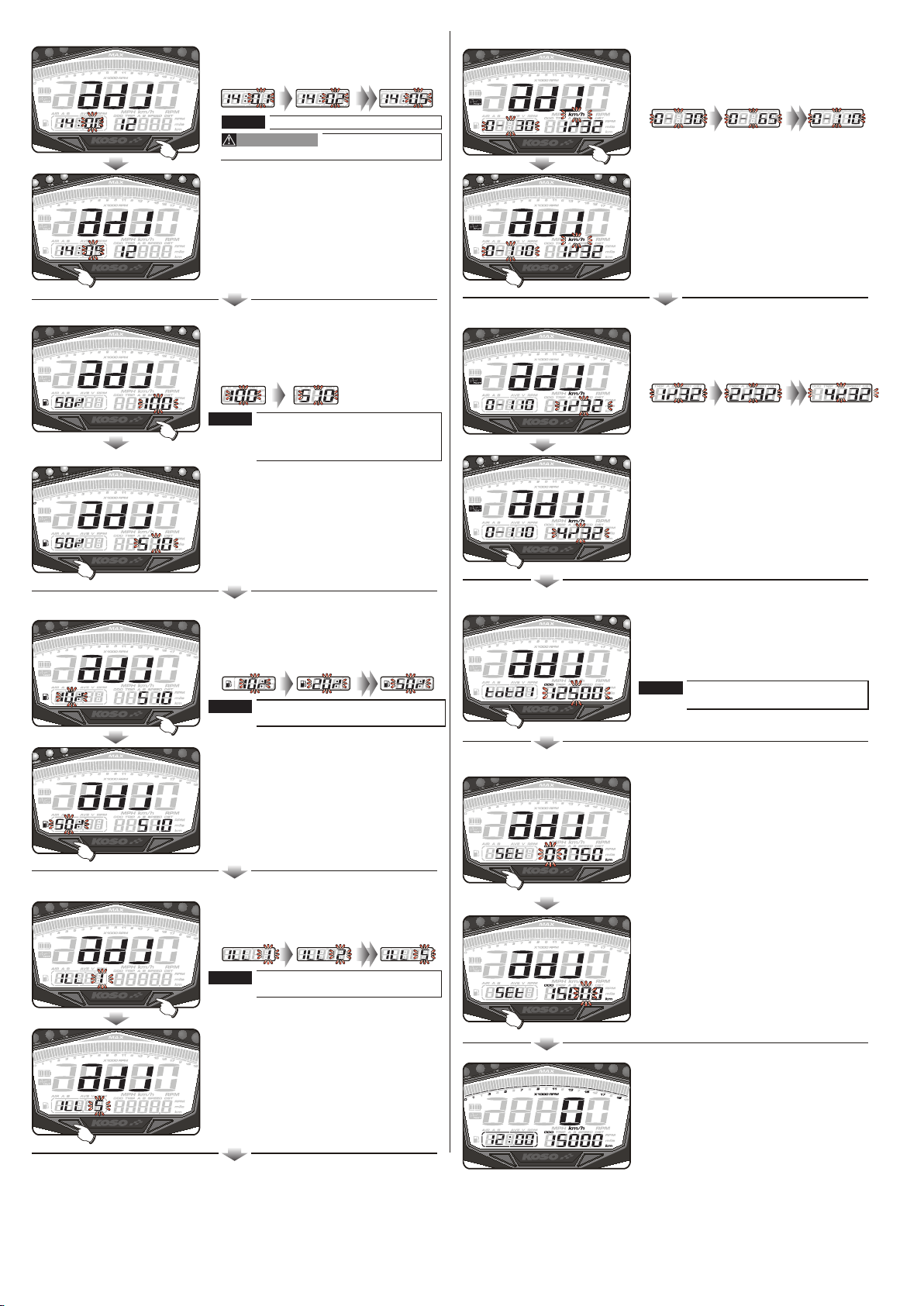

If you don't reach the target

speed or stop accelerating

during the test, press the

Adjust button to stop the

timer. Press the Adjust button

once to clear the record and

enter the target speed timer test screen.

Speed up

Test

failure

3 km/h0 km/h

During the test recording, the will ash!

When the bike moves, the timer will

start automatically.

About the power test

setting, please check (4-2)

0 km/h 3 km/h 110 km/h

5-1

5-2

Target speed timer test

WARNING!

In power test screen, press the Select button

once to enter the target speed timer

test screen.

Use this function at racetrack to avoid

trac accidents.

Please start the test while the

is not moving

If you already have a record, it will

display the record rst. You must clear

the record before starting a

new test.

Press the Adjust button to clear the

record and enter the target speed

timer test screen.

EX. You now see the previous

record. It is displaying the target

speed timer setting (0~110 km/h),

the test result (19”20 s), the top speed

(110 km/h) during the test and the

MAX RPM (10,000)

The record

display screen

To enter the

testing screen

To enter the thesting screen if there is no record

To enter the thesting screen if there is no record

The timer is automatic, so

moving the bike will start

the timer and stop when

your bike stops moving.

Speed up

Target distance timer test

WARNING!

Use this function at racetrack to avoid

trac accidents.

Please start the test while the

is not moving

If you already have a record, it will

display the record rst. You must clear

the record before starting a

new test.

In power test screen, press the Select

button 2 times to enter the target

distance timer test screen.

Press the Adjust button to clear the

record and enter the target distance

timer test screen.

EX. You now see the previous

record. It is displaying the target

speed timer setting (2/32 mile (100M)),

the test result (10”27 s), the top speed

(63 km/h) during the test and the

MAX RPM (8,000).

When the bike moves, the timer will

start automatically.

About the power test setting,

please check 4-2 .

The timer is automatic, so

moving the bike will start

the timer and will stop when

your bike stops moving.

Speed up

0 M100 m

If you want to test it again, press the Adjust

button to clear the record and enter the target

speed timer test screen again.

If you don't reach the target

speed or stop accelerating

during the test, press the

Adjust button to stop the

timer. Press the Adjust button

once to clear the record and

enter the target distance timer test screen.

Speed up

Test

failure0 M

●In main screen, press and hold the

Adjust button 3 seconds to enter the

target speed timer test setting.

●In main screen, press & hold the

Adjust button 3 seconds to enter the

target distance timer test setting.

If you just want to use the function once,press

& hold the Select button for 3 seconds to save

the records and back to the main screen.

If you just want to use the function once,press

& hold the Select button for 3 seconds to save

the records and back to the main screen.

When you reach the set target speed

(0~110 km/h), the timer will stop

counting (19”20 s) automatically.

When you reach the set target distance

(100 M . 2/32 mile), the timer will stop

counting (19”20 s) (10”27s)automatically.

If you want to test it again, press the

Adjust button to clear the record and

enter the target speed timer test

screen again.

If you just want to use the function once,press & hold

the Select button for 3 seconds to save the records

and back to the main screen.

If you just want to use the function once,press & hold

the Select button for 3 seconds to save the records

and back to the main screen.

wh022ba04d-5

NOTE

NOTE

NOTE

NOTE

P. S

P. S

P. S

P. S

TIME TIME TIME

TIME TIME TIME

TIME TIME TIME

During the test recording, the will ash!

The record

display screen

To enter the

testing screen