Rekluse Core EXP - Hydraulic Page 10

26. Repeat the previous 3 bleeding steps until air

no longer comes out of the bleed port. Then,

check that the clutch lever functions properly.

Repeat the bleeding procedure if necessary.

27. Finally, remove the bleed tube.

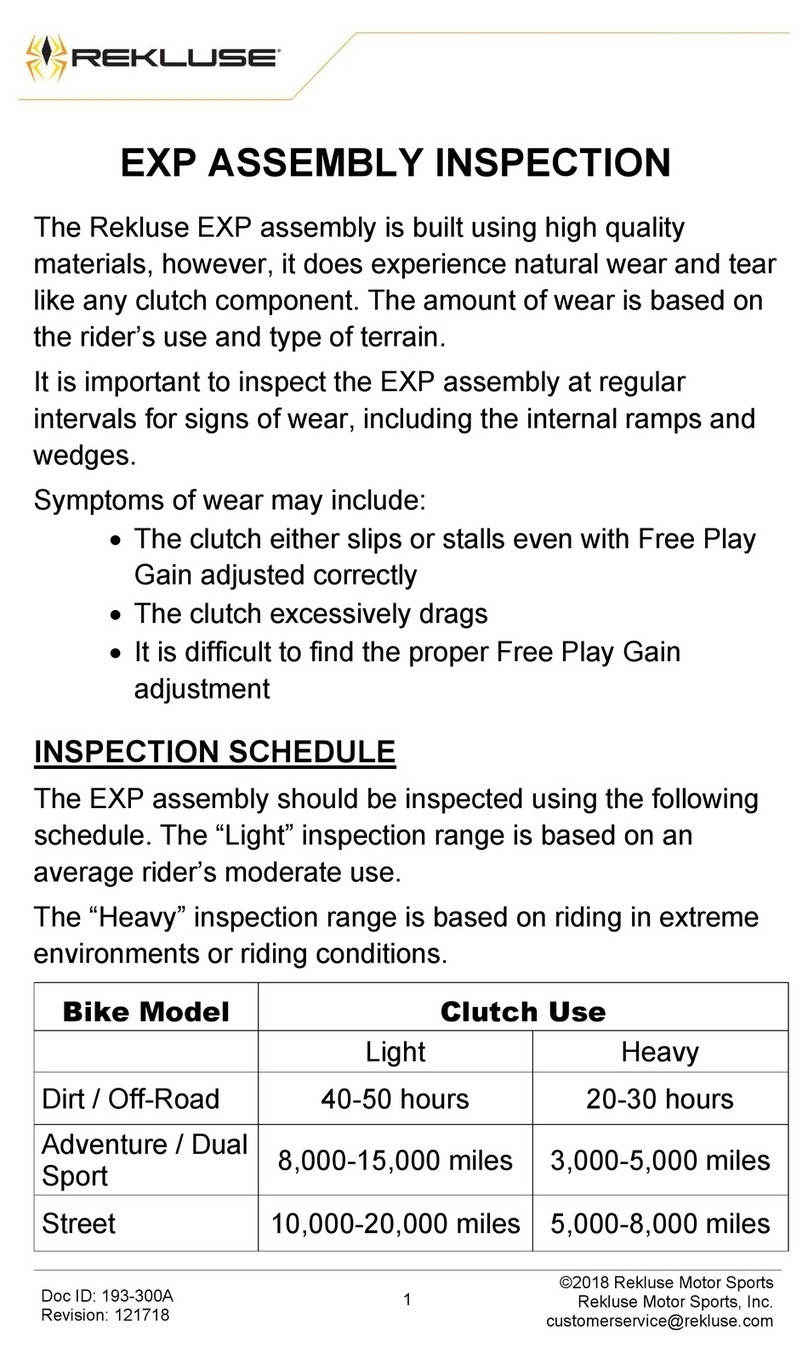

INSTALLED GAP SETTING

DEFINITION: “Installed Gap” is the separation in

the clutch pack created by the adjustment of the

Adjuster Screw in the Slave Cylinder. This gap is

what allows the clutch to spin freely until the

desired RPM is reached for engagement; it must be

set correctly for optimal performance.

28. Using the long end of a 4mm Allen key, turn the

adjuster screw clockwise until it stops under

moderate pressure. You are trying to feel for

the point at which the throwout will start to lift

the pressure plate. This is the “starting point”.

NOTE: It may take a few tries to find the point

at which the system is bottomed out. You

should feel a distinguishable change in turning

effort at this point.

29. Once you have found the starting point, turn the

adjuster clockwise 1 full turn plus 5 marks

(or “1+5”). This is NOT your final setting, but

it is a good reference point for using free play

gain to find the correct setting.

30. Top off the master cylinder with clutch fluid and

reinstall the OEM cap and bladder.

CHECKING

FREE PLAY GAIN

WARNING

Always make sure that the bike is in NEUTRAL before

checking Free Play Gain. Failure to do so may result in

the bike lurching forward, and loss of control and/or

injury may result.

NOTE: Before performing this step,

please visit our website at

rekluse.com/support to view the

TECH VIDEO entitled “How to Check

Free Play Gain”.

“Lever Free Play”is essentially the “slack” in the

clutch lever before it starts actuating the clutch.