Disclaimer: Relationshipware LLC and its members are NOT

RESPONSIBLE for any injury or loss of property to any

person suffered while operating this water rocket launcher.

*** If the bottle fails to release from the launcher or it is aimed in an

unsafe direction and you are exceeding 120 PSI, then ABORT your

launch. Carefully pull the safety valve ring to release the air pressure

within the bottle; than one can remove the bottle from the launcher.

StratoLauncher®IV Launch Instructions

Please read operating instructions carefully before launching

any plastic bottles. Designed for ages 10 and over. Operate

launcher with extreme care and only under adult supervision.

WARNING: Do NOT allow anyone to touch the bottle after pumping has

begun. Do NOT aim the bottle at anyone or any other object, either public

or private. Do NOT stand over the bottle. Do NOT impact the bottle under

pressure as it may shatter. Do NOT exceed 120 PSI inside the bottle.

Safe & Secure

Choose a safe area such as a huge field or

park away from people, trees, and resi-

dences to launch plastic bottles (rockets).

Although no pulling action against the

launcher is required to release the rocket,

securing the base with 1 or 2 tent pegs

(not included) may help avoid accidental

tip over during use.

Launcher supports most .5L, 1L, 1.25L and

2 liter plastic (PET*) bottles.

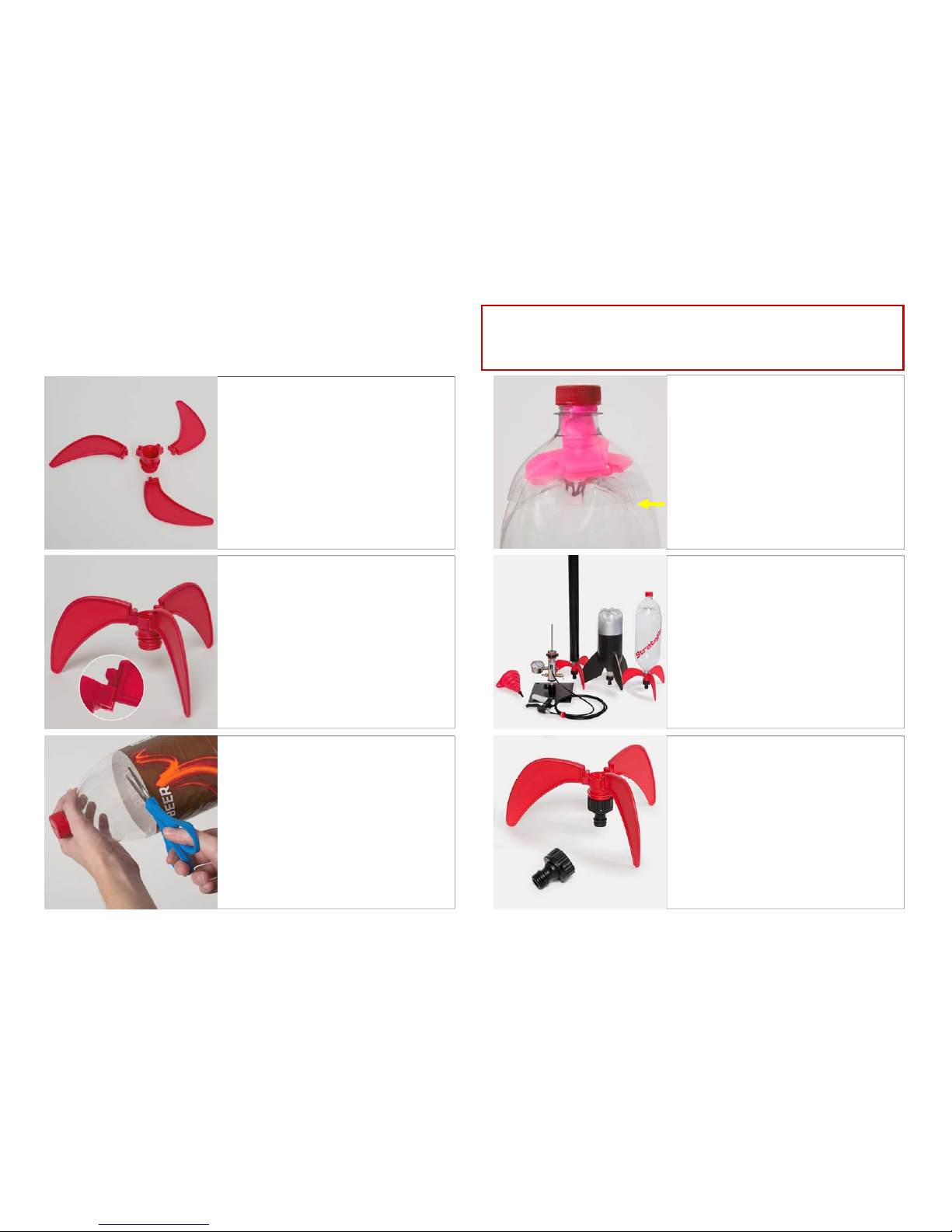

Mount Rocket

Tilt the entire launcher to the side, parallel

with the ground, and slide the bottle over

the 1/4" SS tube. Press the bottle against

the Q-Release hose connector until it locks

with a loud click. Place the launcher on the

ground and secure with tent pegs if de-

sired. Alternate method: hold your finger

over the nozzle and place the bottle above

the 1/4" SS tube, then rapidly remove your

finger and push the bottle over and down

the tube and lock in the hose connector.

Prepare Trigger

Fully stretch out the brake cable on the left

side of the launcher parallel with the tank

valve. Insert the black cable housing into

the manifold cable stop, push Q-Release

hose connector down & place nipple into

clamp-on cable stop. Remove any excess

cable slack with brake lever adjustments.

* Polyethylene terephthalate (aka PET) is a thermo-

plastic polymer resin of the polyester family that is

used in soda pop bottles. Serious bodily injury could

result from using any other type of bottle.

Funnel Fill

Inspect your PET* bottle for any damage

or potential problems. If in doubt discard

the bottle and employ another.

Use only water and/or air for fuel.

Insert the red funnel into the bottle & fill the

funnel to the brim quickly and stop pouring.

This will yield the ideal amount of 1 cup

(notice the water level near the score mark

on the 1/4" SS tube when the bottle is

mounted on the launcher).

Water Fill Upgrade Kit

StratoLauncher IV Ultimate kit contains an

upgrade kit that can be purchased sepa-

rately, which enables the use of a tank

sprayer (available at local hardware stores)

as your water fill source. A 2 gal. tank will

yield about 30 launches. Pressurize the

tank by pumping 10 or more times. Open

the mini ball valve on the launcher until the

water level touches the score mark on the

1/4" SS tube, and then close for efficient

and spill free fueling.

Pump & Launch

Attach the air source** to the Schrader

valve on the launcher. Be sure all persons

are at least 10 feet away from the

launcher, then begin pumping. Launcher

supports air pressures between 10 PSI up

to 120 PSI***. Stop pumping once you

achieve the PSI that you desire. Place

nose cone on rocket. Squeeze the brake

lever from a safe distance and out of the

splash zone to launch the rocket. Enjoy!

** Sources for compressed air include a bicycle pump,

a foot pump for a car, scuba tank, or air compressor.

1

2

3

4

5

6

Copyright © 2017 by Relationshipware LLC