2www.relax-a-mist.com1-800-Y-U-STEAM (1-800-987-8326)

INSTALLATION INSTRUCTIONS - CR-12 & CR-14, 3PH

2. ROUGH-IN

WATER SUPPLY (According to Local Plumbing Code)

a water hammer arrester (water bumper) is recommended.

To maintain a proper water level in the generator, the water

corrode the steam generator, install appropriate water treatment.

See CAUTION 4 and Warranty Policy. See diagrams on Page 6.

DRAIN VALVE OPTION (According to Local Plumbing Code)

A 3/4 inch rigid copper pipe must be installed from

ELECTRICAL - WATTS, WIRE AND FUSE SIZES

(According to Local Electrical Code - Use Copper Wire Only -

Must be Installed by a Qualied Electrician)

circuit breaker must be of adequate size to carry the

necessary amperage to operate the steam generator.

away from the area above the steam diusers), to install the

Quick Touch Timer (found in the appliance electrical box), and

wall material and pass the female end of the cord set through

OR, the Time and Temperature

purchased separately).

There is one class 1, 3 conductor copper wire and

ground power cable, and one, factory supplied, class 2

25 foot control wire to be run to the steam generator:

a) Run a copper power supply cable, 3 wire

and ground, of adequate gauge to carry the

necessary amperage from the fuse or circuit

ELECTRICAL SUPPLY & PIPING

See CAUTION 8-10.

SUPPLYCANNOT

Use Copper Supply Wire Only.

The copper power supply cable must run directly from the fuse

or circuit breaker to the steam generator. The factory supplied

cord set must be run directly from the steam generator to

in the steam generator, through the class 2 voltage circuitry.

STEAM PIPING TO BATH OR SHOWER

from the steam generator to where it will enter the steam

WARNING: STEAM DIFFUSERS ARE HOT AND CAN CAUSE

SEVERE BURNS. LIVE STEAM IS 212 °F (100 °C).

The 3/4” end of the steam pipes at the steam room should have

IMPORTANT - Ensure the

elbows are perpendicular to the nished wall on two axis.

Check their orientaon by threading in a nipple that extends

past the studs and out beyond the nished wall. This way

4 turns), so it will protrude through the wall into the steam

nipples will be replaced by brass nipples of the appropriate

length. See Final Installaon Steam Piping and Fig. 3.

STEAM GENERATOR: CR-12 CR-14

208 VOLTS

*

o

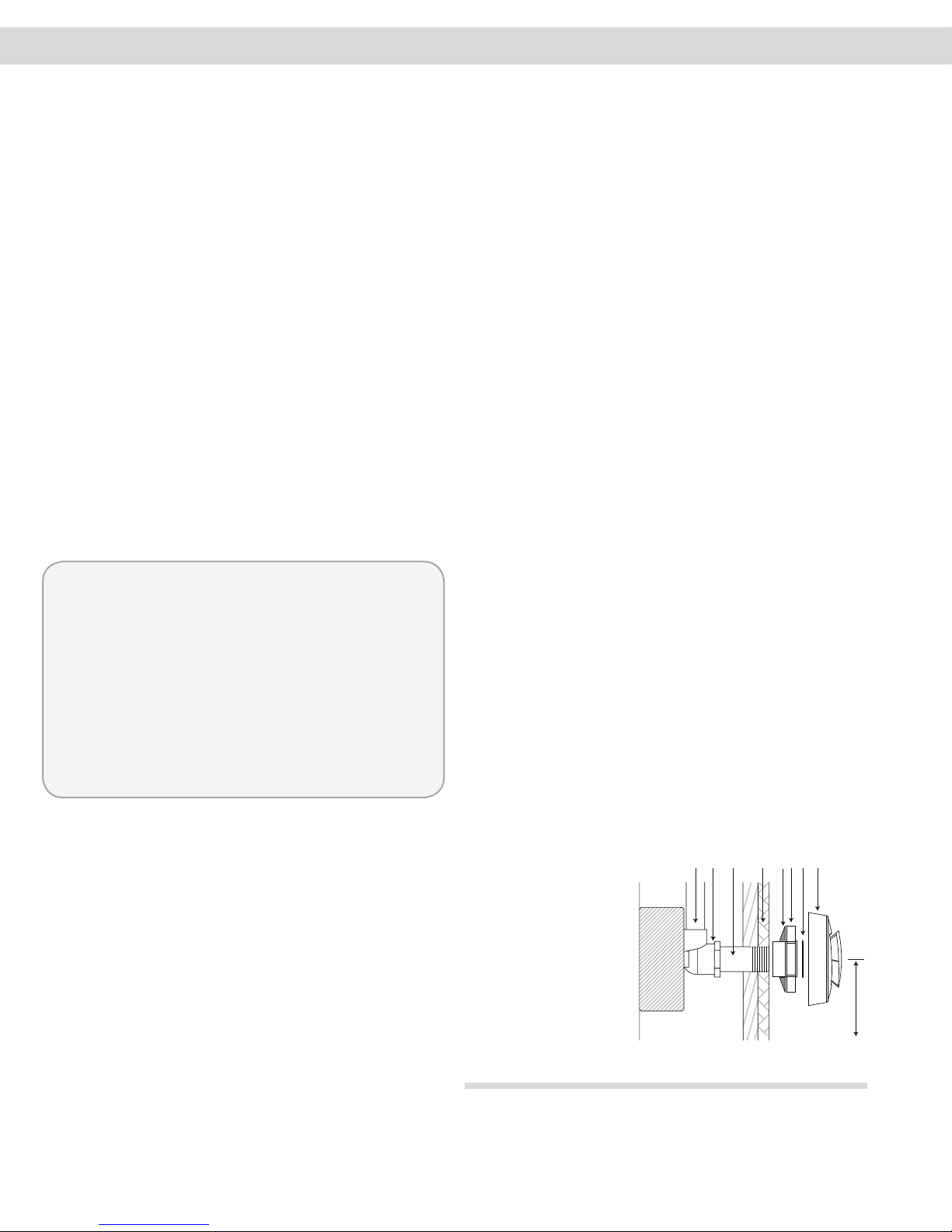

Fig. 3

1- Steam diuser

2 - O-ring

3 - 3/4” C x FIP adapter

4 - Sealer (silicone)

5 - Finished wall

6 - 3/4” brass nipple

7 - 3/4” C x C wing-back

elbow

8 - 3/4” copper pipe type “L”

9 - 12” from steam pipe to

steam room oor.

15 3 2

4

678

9

WARNING: STEAM DIFFUSERS ARE HOT AND CAN CAUSE

SEVERE BURNS.