03

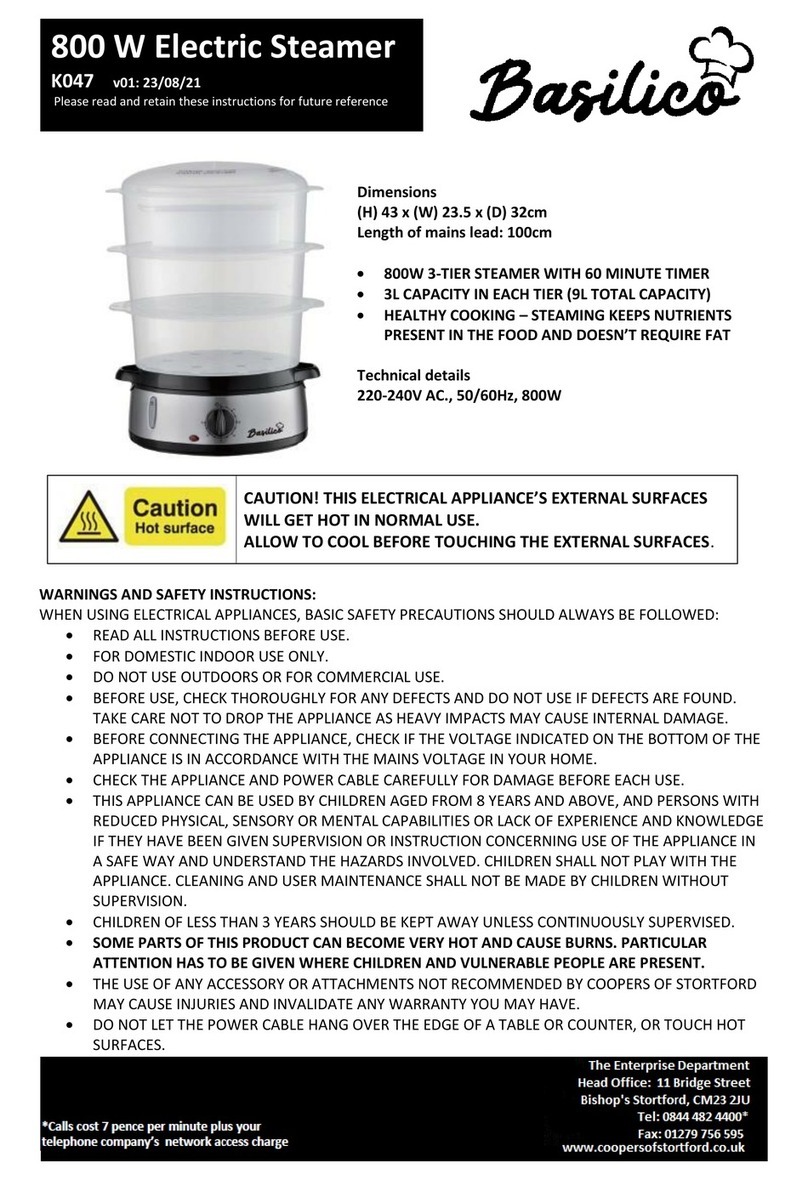

IMPORTANT SAFETY INSTRUCTIONS.

SAVE THESE INSTRUCTIONS IN A SAFE

PLACE FOR FUTURE REFERENCE

READ ALL INSTRUCTIONS BEFORE USE

When using your Reliable steam station, basic safety precautions should always be

followed. Please read the following instructions carefully as they provide important

information concerning how to install, use and care for this product.

1. To protect against the risk of electric shock, do not immerse the appliance

in water.

2. Do not allow the cord to touch hot surfaces.

3. Always allow the appliance to cool for at least thirty minutes before storing.

4. Always put the appliance in a secure place on a table or counter when using.

5. Do not move the appliance without unplugging it first.

6. Always disconnect the appliance from the outlet before filling with or removing

water. Be careful to avoid spilling water on the appliance when filling.

7. Use tap water or 50/50 tap/distilled water in the appliance. Do not use per-

fumed or products containing alcohol in the appliance.

8. Always disconnect the appliance when not in use.

9. Do not use the appliance if the cord is damaged. Return the appliance or have

the cord repaired by the manufacturer, or their service agent.

10. Do not operate the appliance if it has been dropped or damaged. Do not

disassemble the appliance. Incorrect reassembly can cause a risk of electric

shock. Send it to an authorized service center for repair.

11. Do not operate another high wattage appliance on the same circuit.

12. This appliance must be grounded. Do not alter the plug or attempt to remove

this feature.

13. Be careful. Burns can occur from touching hot metal parts or steam.

14. This appliance is not intended for use by young children.

15. While using the appliance, never unscrew or remove the cap (5) while the

boiler is under pressure.

16. Before removing the cap, make sure there’s no more steam in the steam

chamber by shutting the boiler switch (2) to the off position, and pressing the

steam iron button (11) to release all of the remaining steam.

17. To ensure your safety, the safety cap (5) and all other components must be

replaced with original parts only.