Abbreviations

Below are a list of abbreviations that are used in this booklet:

BCW Boosted Cold Water PHE Plate Heat Exchanger

DHW Domestic Hot Water TBPV Thermostatic Bypass Valve

DPCV Differential Pressure Control Valve THCV Thermostatic Heating Control Valve

FBP Flushing Bypass TIU Thermal Interface Unit

FFR First Fix Rail TRV Thermostatic Radiator Valve

MCB Miniature Circuit Breaker UFH Under Floor Heating

General Information

Radiance®Thermal Interface Units are part of a heating network which is supplied from a central

boiler room. They are designed to provide space heating and domestic hot water to an residence.

The TIU is generally located within the apartment and connects to a heat network and boosted

cold water on the primary (supply) side and to the space heating and DHW outlets on the

secondary side.

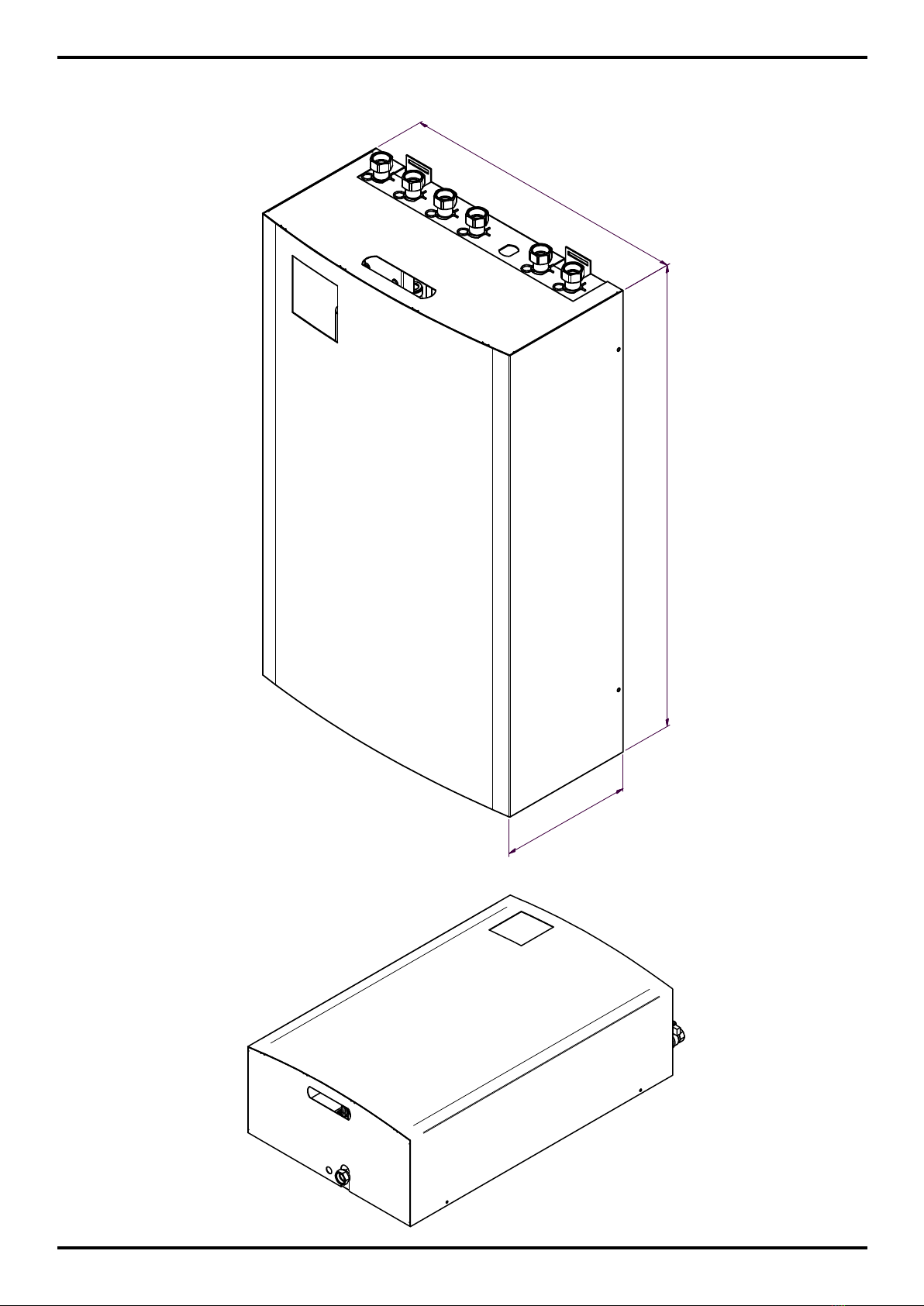

Product Description - Rapid (RTIU702XXX)

The Rapid family of Radiance TIUs are designed to supply indirect heating (hydraulically

separated between the primary and secondary circuit by a plate heat exchanger) and

instantaneous DHW. The hot water is heated at the time of use in a plate heat exchanger and not

stored in a cylinder.

Intended Usage

Radiance TIUs must be installed by a competent person to ensure they perform as designed.

All pipe connections and electrical connections must to be completed by trained professionals

according to and conform to IEE regulations.

Technical Description

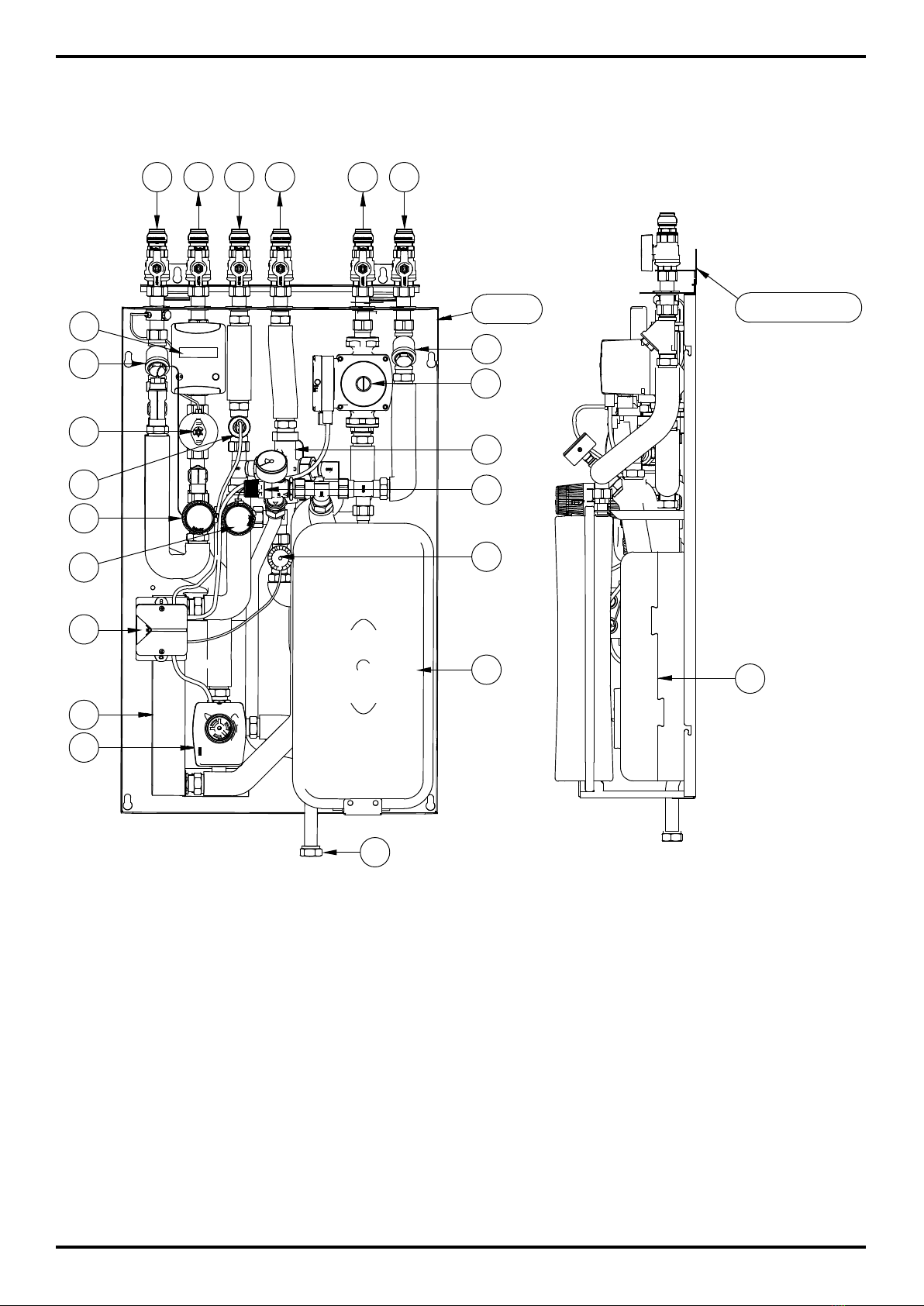

The Rapid family of TIUs are twin-plate (2 PHE) units designed to provide space heating and

DHW. The unit connects the primary heat network, the secondary space heating (radiators or

UFH) and to the BCW supply to produce DHW.

Heating Controls

There is no hydraulic by-pass included on the secondary side of the Rapid TIU. This means that

the external controls need to switch off the “call for heat” when all valves of the heating system

are closed and there is no demand. This will prevent the circulation pump running against a

closed system and consequently overheating.

This issue is normally overcome by fitting the heating controls in the coldest room (for example

the hall) where the radiator should not fitted with a TRV and all valves at the radiator are

fully open. The room thermostat should not be installed in direct sunlight. The hall will now

be temperature controlled by the room stat/timer and the radiator in the hall also performs a

hydraulic bypass to the unit. All other radiators in the system should be fitted with TRVs.

6