1 . INTRODUCTION

1.1. This manualcontains information applicable only to

the Reliance@ Model 5200 Chair.

1 .2. Wheneveryou see the symbols shown below, heed

their instructionsl Always follow safe operating and

maintenance practices.

'WARNING" _ THE WARNING SYMBOL

IDENTIFIES SPECIAL INSTRUCTIONS OB

PROCEDURES WHICH, IF NOT CORRECTLY

FOLLOWED, COULD RESULT IN PERSONAL

INJURY.

'CAUTION' * This caution symbol identif ies

special instructions or procedures which, if not

strictly observed, could result in damage to or

destruction of equipment.

"NOTE" - Note indicates points of particular or

additional information.

1 .3. Should your product not pedorm properly, or if you

have any questlons concerning lhe use and care of any

Relianceo product, contact the Reliance@ Distributor,

where you purchased this productorcontactthe Technical

Service Department, Reliance@ Medical Products, lnc.,

3535 Kings Mills Boad, Mason, Ohio 45040-2303, or call

(800) 735-0358.

NOTE: Always have the model number and serial

number available before contacting Reliance@ or your

authorized Relianceo Distributor.

2. INSTALLATION

2.1. Unpacking

2.1.1. Open the shipping carton carefully and record

any shipping damage to the carton or to the contents.

2.1.2. Remove the upper portion of the crate from the

skid and unbolt the base clamping boards. lt is recom-

mended that the crate be located adjacent to the spot

where it is to reside before unpacking the upper struc-

ture. This is so that the chair can slide olf of the skid and

right into place. Do not litt the chair by the upper struc-

ture, although the chair may be tipped or slid by pushing

or pulling the upper structure.

2.1.3. For shipping purposes, the chair back has been

tilted Jorward and tied. Remove the string. To secu re the

chair back in the proper upright position, locate the seat

supporl casting underneath and to the rear of the chair

back. From either side, remove the E-clip retaining ring

and spacer. Pull the pin out. Pull the chair back to the

upright position and align the gas spring clevis wlth the

center of the seat suppon casting. Replace the pin and

spacer. Reattach E-clip.

2

2.1.4. Asmalltool packel containing tour hexagon allen

wrenches, sizes 1/8, 3116, 3132, and 5/64, has been

included in the shipping carton.

2.2. Assembly L,

Remove allwrappings. Onlythe headrest has been

removed lor shipment.

2.2.1. Chair Cushions

The cushions on the back and seat of the chair are

identical. To vary stress points/wear patterns on the

upholstery, it may be desirable to periodically reverse

the cushions (back to seat, seat to back).

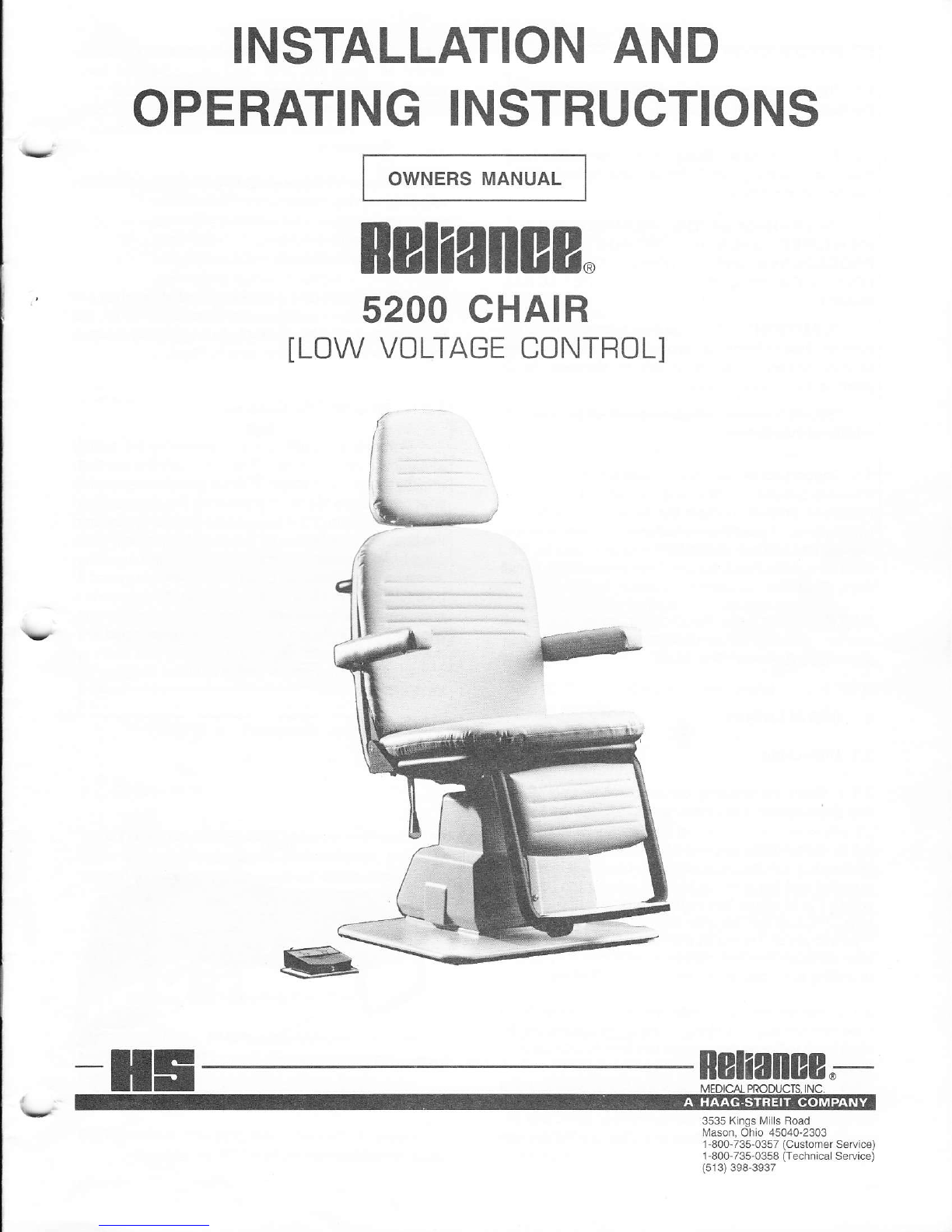

2.2.1. Mounting the Headrest

Remove the back cushion assembly by pulling

straight out from the chair. The seat cushions are both

attached with velcro strips. This will permjt access to the

seat-back. Slide the pivot bracket on the headrest into

the slot in the top of the back cover (Figure 1), and into

the bracket mounted under the chair back cover. lf the

pivot bracke't does nol drop in smoothly, the mounting

screw (slightly o{f-center in the chair back) may need to

be backed out 10 allow the bracket to fit. This screw is a

socket head set screw which requires a 1/8 hexagon key

allen wrench (included in the tool packet shipped with Y/

the chair) to loosen. When the bracket has been in-

stalled, tighten the screw until it is snug. Replace the

back cushion.

FIGURE 1

tN - 5200

\r-