Table of Contents

SECTION 1 –GETTING ACQUAINTED ...................................................................................................................... 1

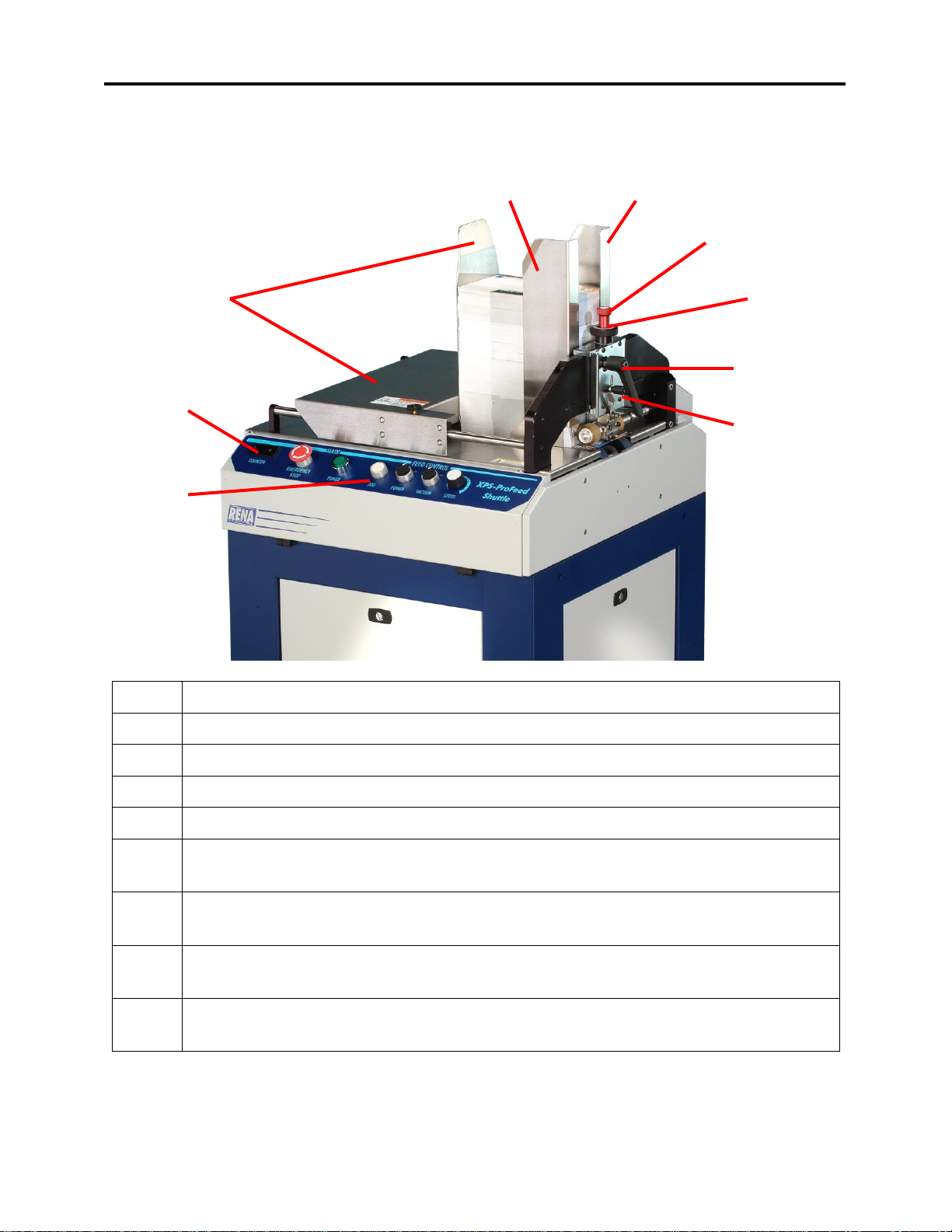

MAIN CONTROL PANEL....................................................................................................................................................2

MEDIA THICKNESS AND SEPARATOR KNOB ..........................................................................................................................2

SHEET LENGTH SWITCH....................................................................................................................................................2

SECTION 2 –INSTALLATION ................................................................................................................................... 3

POWER REQUIREMENTS...................................................................................................................................................3

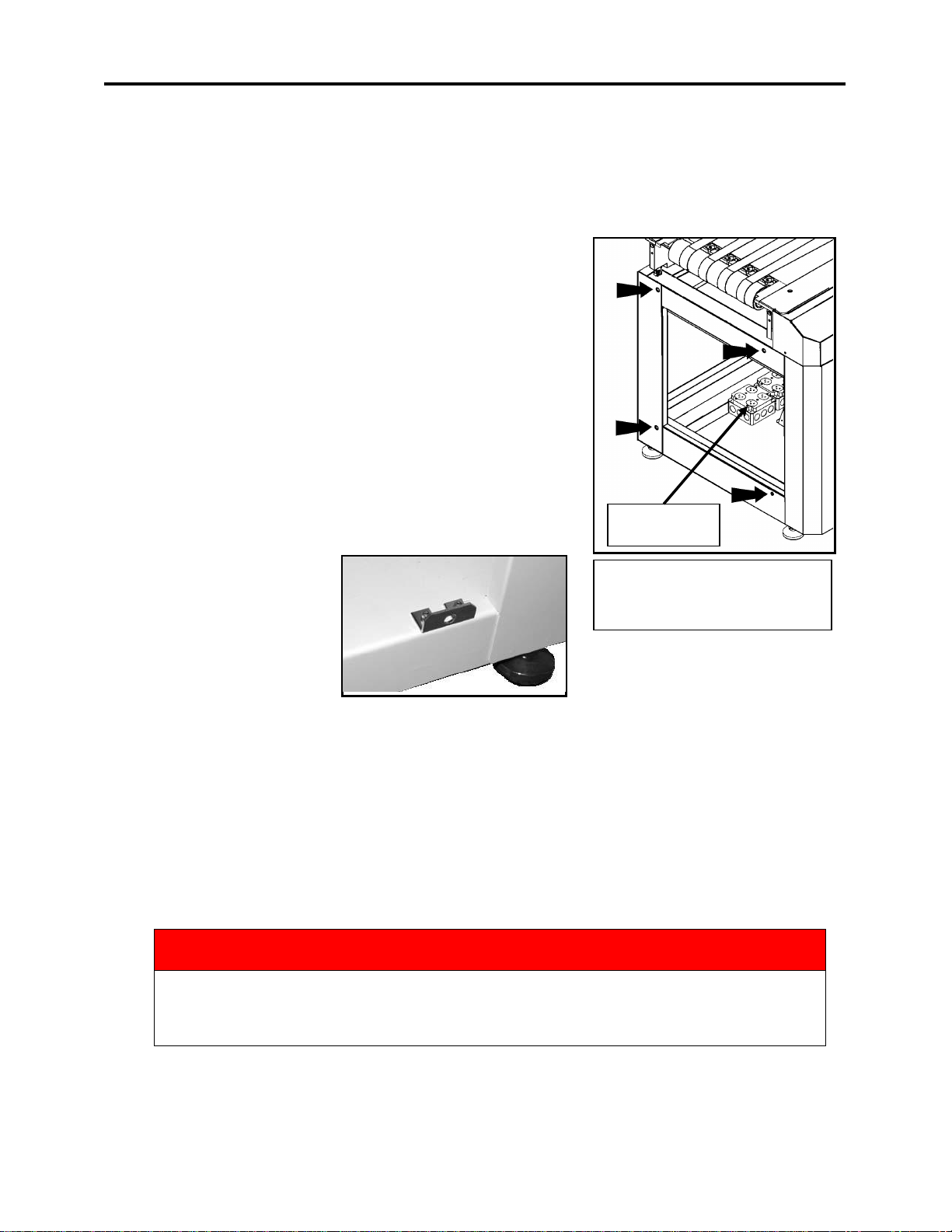

ATTACHING TO THE XPS-PROMAIL BASE ............................................................................................................................3

Connecting Power and Interface Controls to the XPS-ProMail Base......................................................................3

Feeder Interface Cables .........................................................................................................................................4

STAND-ALONE OPERATION ...............................................................................................................................................4

CONNECTING THE SHUTTLE FEEDER TO OTHER SYSTEMS.........................................................................................................5

SECTION 3 –SETUP AND OPERATION..................................................................................................................... 6

SETTING UP THE FEEDER ...................................................................................................................................................6

Step 1 - Verify the Vacuum Shuttle is at the “Home” Position ...............................................................................6

Step 2 - Choose and Install the Proper Vacuum Plate............................................................................................7

Installing Reversible Rear Media Sleds (Pusher).................................................................................................................. 8

Installing the Rear Media Support Accessory ...................................................................................................................... 9

Step 3 - Adjust the Forwarding Rollers to Accommodate the Media Thickness...................................................10

Step 4 - Adjust the Sheet Separator .....................................................................................................................10

Step 5 –Adjust the Guides ...................................................................................................................................11

Step 6 –Set the Sheet Length Switch...................................................................................................................11

OPERATING THE FEEDER.................................................................................................................................................11

FORWARDING ROLLER ALIGNMENT ADJUSTMENT ...............................................................................................................12

SECTION 4 - MAINTENANCE ................................................................................................................................. 14

General Cleaning..................................................................................................................................................14

Cleaning the Media Sensor ..................................................................................................................................14

CLEANING FEED ROLLERS ...............................................................................................................................................14

Cleaning the Jar Filter ..........................................................................................................................................15

CLEANING VACUUM PUMP FILTERS..................................................................................................................................15

SECTION 5 –TROUBLESHOOTING......................................................................................................................... 16

Feeder Power Won’t Turn ON (in Stand-Alone Mode):........................................................................................16

Feeder Power Won’t Turn ON (when Interfaced to XPS-ProMail Base):..............................................................16

Feeder Won’t Start to Feed (Forwarding Rollers turn but Vacuum Shuttle not moving):....................................16

Skewing:...............................................................................................................................................................16

Hesitation: ...........................................................................................................................................................17

Jamming: .............................................................................................................................................................17

Removing Jams in the Feeder ..............................................................................................................................17

APPENDIX –SPECIFICATIONS ............................................................................................................................... 18