AN1957 Rev 0.00 Page 2 of 6

September 5, 2014

ISL91134IIQ-EVZ

Functional Description

The ISL91134 implements a complete boost switching regulator,

with PWM controller, internal switches, references, protection

circuitry and bypass control. The ISL91134 is designed to support

5V output voltage. A voltage select pin (VSET) is available to scale

up the output voltage by a small offset to compensate the load

transient droop. The evaluation boards have been functionally

optimized for best performance of the ISL91134. This part

requires only an inductor and a few external components to

operate. The 2.5MHz switching frequency further reduces the

size of external components. The input power and load

connections are provided through multi pin connectors for high

current operations.

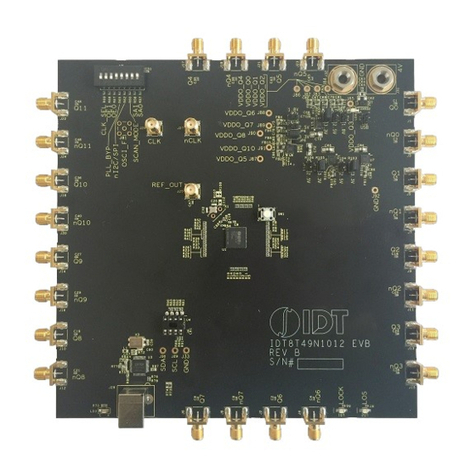

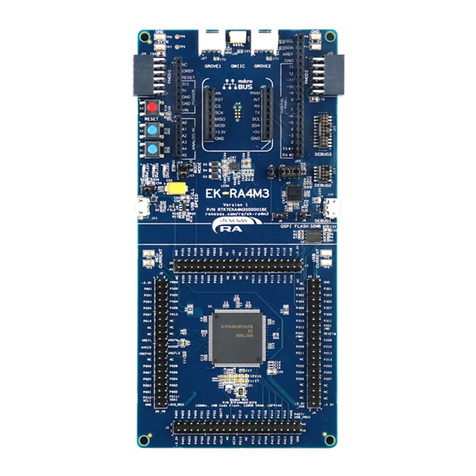

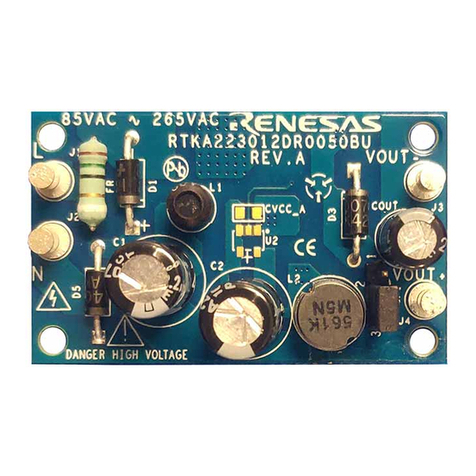

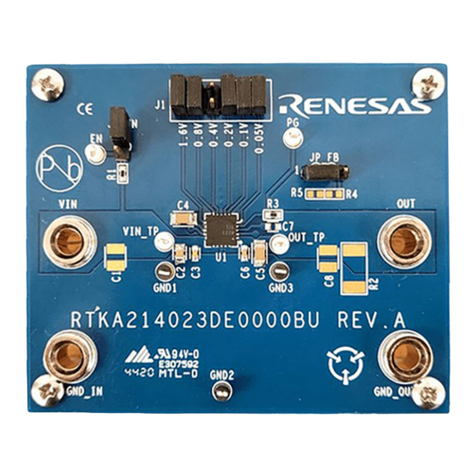

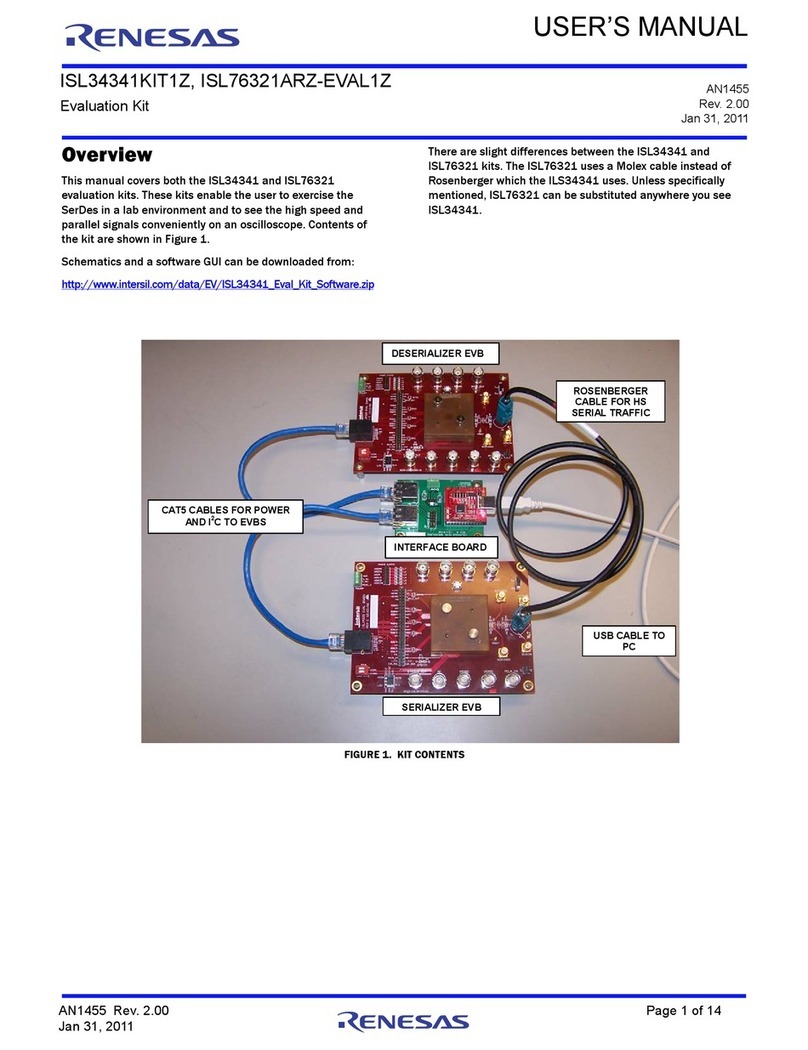

The ISL91134 evaluation board is shown in Figures 3 and 4. The

board’s enable function is controlled by the on-board jumper header

J3. Similarly, the VSET function is controlled by the on-board jumper

header J4 and the BYPASS function can be set to Forced or Auto

mode by controlling the on-board jumper header J5.

The schematic of the ISL91134-EVZ evaluation board is shown

on page 4.The PCB layout images for all layers are shown in

Figures 5 and 6. The bill of materials of the ISL91134-EVZ is

shown in Table 1.

Operating Range

The VIN range of the boards is 2.35V to 5.4V. The VOUT for the

ISL91134 is 5V. The IOUT range of the boards is 0 to 2A. The

operating ambient temperature range is -40°C to +85°C.

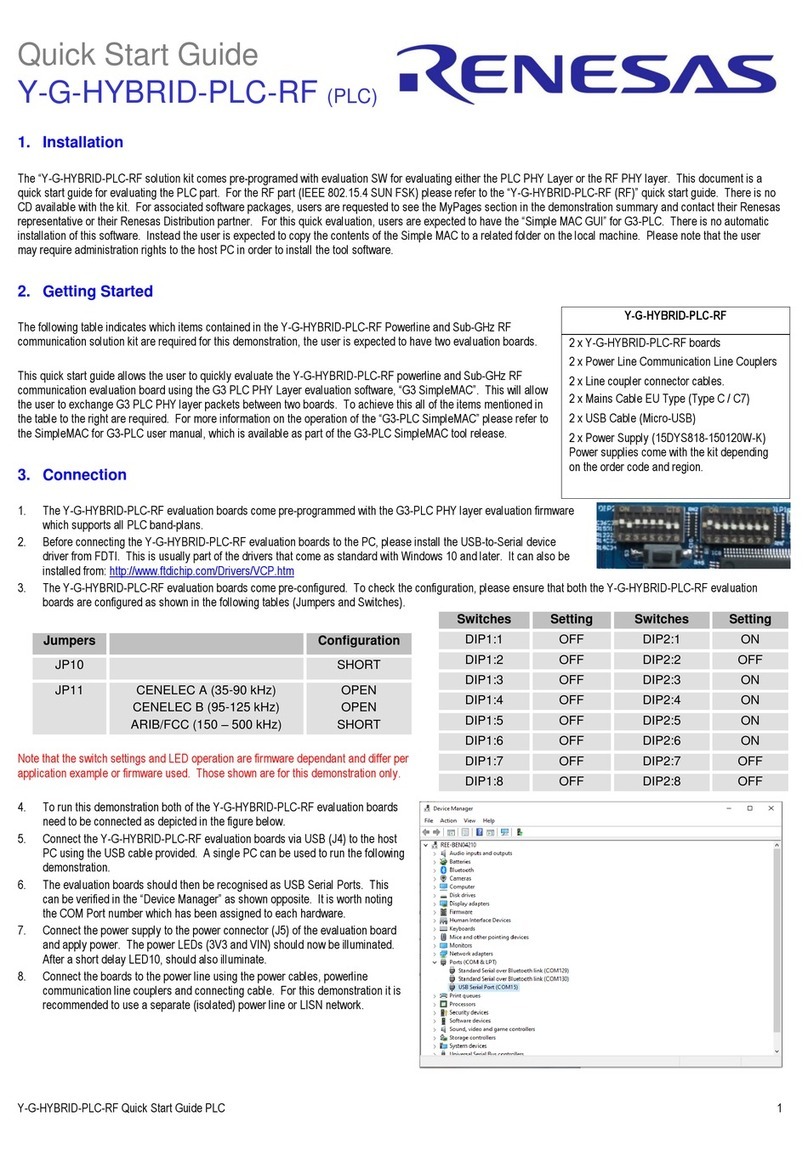

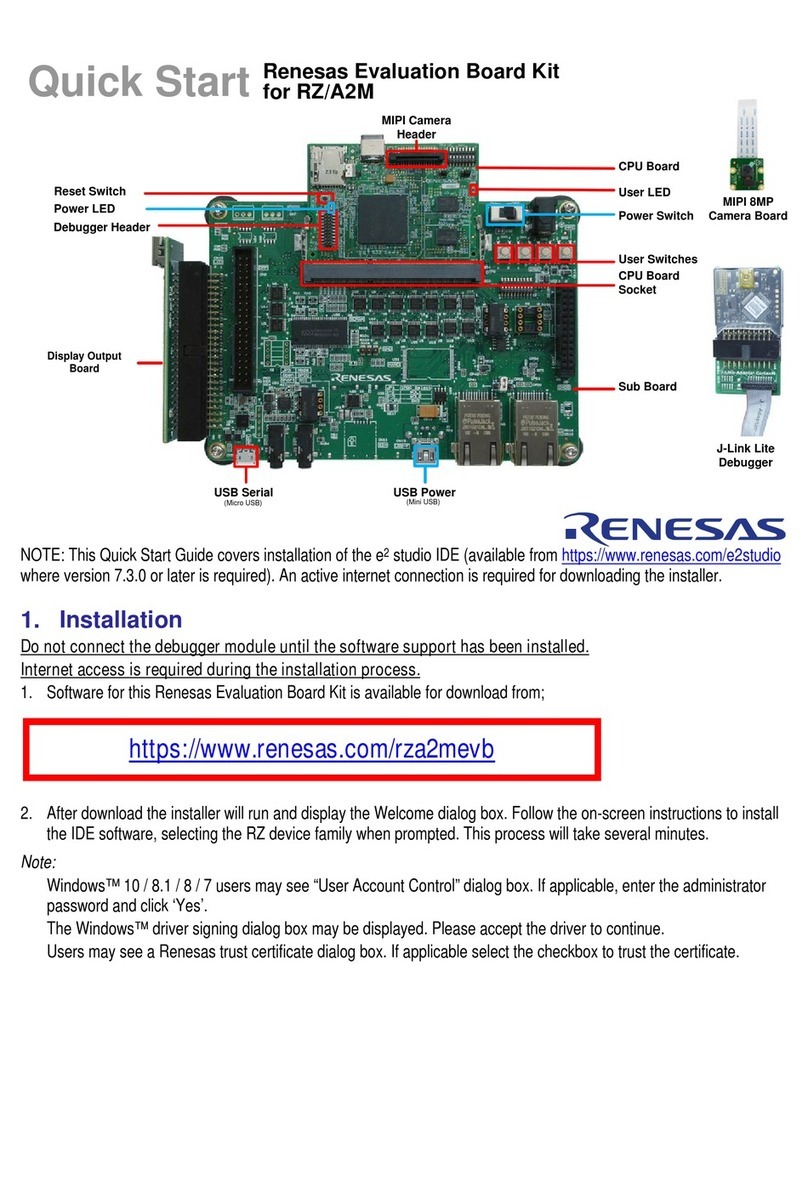

Quick Start Guide

For the ISL91134 board, the voltage can be set to 5V with

VSET = 0 and 5.2V with VSET = 1.

Refer to the following Quick Setup Guide to configure and

power-up the board for proper operation. During the power-on

process, the expected waveforms are shown in Figure 2.

Quick Setup Guide

1. Install jumpers on J3 shorting EN to VIN.

2. Install jumper on J5 shorting BYPS to VIN, auto bypass mode.

3. Install jumper on J4 shorting VSET to GND or leave it as NC.

4. Connect power supply to J1, with voltage setting between

2.35V and 5.4V.

5. Connect electronic load to J2.

6. Place scope probes on VOUT test point, and other test points

of interest.

7. Turn on the power supply.

8. Monitor the output voltage VOUT = 5.05V when VIN < 5V (Boost

mode), VIN = VOUT when VIN > 5.15 (bypass mode), the supply

current should be ~110µA (boost mode) and ~95µA in (auto

bypass mode). In forced bypass (BYPS pin = GND), supply

current should be ~45µA.

9. Turn on the electronic load.

10. Measure the output voltage with the voltmeter. The voltage

should regulate within data sheet spec limits.

11. To determine efficiency, measure input and output voltages

at the test points J1 and TP3. The bench power supply can be

connected to the PVIN and GND headers on J1. The electronic

load can be connected to the VOUT and GND headers on J2

measure the input and output currents. Calculate efficiency

based on these measurements.

Layout Considerations

1. C1is used to compensate for line drops on cables from power

supply to the IC, this will not be required for the actual board

design.

2. The Input capacitor (C2) should be placed close to the IC to

reduce VIN spikes/noise.

3. Output capacitors (C3, C4) should be placed as close as

possible to the IC to minimize VOUT spikes.

4. Boost Inductor (L1) between VIN and LX should be connected

using short and wide traces. It is recommended to use

multiple vias between the LX pin and the inductor. Three vias

of 7mils width were used on the evaluation board.

5. Recommend maximizing copper pour area for VIN, VOUT and

GND for better thermal performance.

6. AGND and PGND of the IC should be connected to each other.

It is crucial to connect these two grounds at a location very

close to the IC.

FIGURE 2. START-UP WAVEFORM 50ΩLOAD