AN1355 Rev 0.00 Page 6 of 15

Oct 10, 2007

ISL9208EVAL1Z

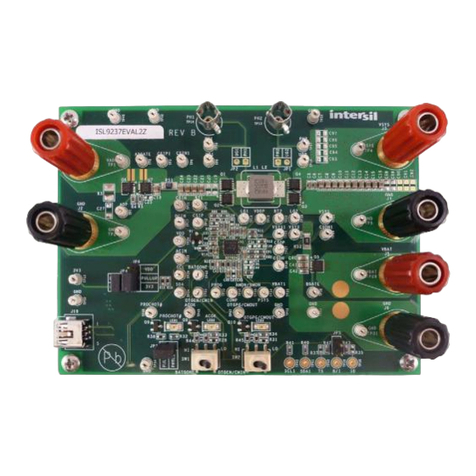

• When the WKUP pin is pulled low, the ISL9208 wakes up

and turns on the RGO output. This turns on the RGO LED.

Sleep/Wake Testing (WKPOL = 1)

• Set the WKUP jumper to the active high position (shunt on

the side closest to the push-button switch).

• Use the GUI to set the “WKUP Pin Active High” in the

Configure Tab, feature set window.

• Put the ISL9208 in sleep mode as before.

• This time, the device can be awakened by the press of the

WKUP button on the board.

Testing with the Microcontroller

• To operate the board using the microcontroller, power-down

the board.

• Set the I2C jumpers to the µC position.

• Power-up the board and restart the GUI. Now, the PC will

be communicating with the microcontroller and the

microcontroller will be communicating with the ISL9208.

• The GUI should power-up with some color. In this case,

the FET controls should be green and the indicators

should be green or red. (Note: there is a 5s delay after

power-up before the microcontroller turns on the FETS, so

the indicators may be red when initially powered up.

Clicking on the “refresh button” after 5s should change the

FET indicators to green). If the GUI is all gray, then there

is a communication problem. If there is a communication

problem, see the troubleshooting guide in the Appendix.

• If the FET indicators remain red after 5 seconds, then it is

likely that at least one input voltage is out of range.

With the microcontroller in place, the board performs a

number of automatic functions. These are:

1. The cell inputs are monitored for too high or too low

voltage. If any of the cell voltages go too high, the charge

FET is turned off. If any of the cell voltages go too low, the

discharge FET turns off. When the voltage recovers from

these excursions back into the normal range, the FETs

automatically turn on.

2. After an overcurrent condition, the microcontroller

monitors the load and turns the FETs back on when the

load is released.

3. The microcontroller monitors the temperature and turns

off the cell balance if the temperature is too high or low.

4. The microcontroller performs cell balancing (once it is

enabled through the GUI).

5. The microcontroller monitors the cell voltages and reports

these voltages to the GUI. The microcontroller A/D

converter accuracy is only 10-bits, thus the voltage

readings are not as accurate as when using only the PC

interface.

• Test the overvoltage and undervoltage conditions by:

–If Li-ion cells are being used, discharge the pack until

one or more of the cells reach the undervoltage limit

and the discharge FET turns off. Then, charge the

pack until the FETs turn on again and continue

charging until a cell overvoltage condition is reached.

–If one power supply is being used, lower the voltage

on the power supply until one or more of the cells

reach the undervoltage limit and the discharge FET

turns off. Then, increase the voltage until the FETs turn

on again and continue increasing the voltage until a

cell overvoltage condition is reached.

–If 7 power supplies are used, then simply decrease or

increase any individual supply until the thresholds are

reached and the FET turns off (or on).

• Test the overcurrent in the same way as before, but this time,

when the load is removed, the FETs should automatically

turn back on. In this case, with the microcontroller operating,

the status indicators in the GUI may not prove to be very

useful because the microcontroller is often doing things too

quickly to display on the screen. To get an indication of the

operation, monitor the voltage at the VMON test point with a

scope.

• Testing the cell balance operation requires the use of

Li-ion cells or requires modifying the board to use 1000

cell balancing resistors. (With 7-cells, a string of 20

voltage divider resistors, and 39 cell balancing resistors,

turning on one cell balance output drops the voltage on

that cell to less than 2.5V. At this voltage, the

microcontroller puts the ISL9208 to sleep).

• Start the cell balance test by first observing if the cell with

the maximum cell voltage exceeds the cell with the

minimum voltage by more than 30mV. If so, note the cell

number of the maximum voltage cell.

• Next, select “CB Max #” to be “1”. This limits the balancing

to only one cell (the one with the maximum voltage).

• Use the CB refresh button (or start auto update) to update

the indicators to see which cell is being balanced (it should

be the maximum voltage cell). Be patient because the

microcontroller will balance for 10s, then turn off balancing

for 2s1, then balance again. Also, if the maximum voltage

cell is very close to the next highest voltage cell, or if there

are many cells within a narrow voltage range, then any of

these cells could be balanced, due to the limited accuracy

of the microcontroller A/D converter.

• Next, select “CB Max #” to be “2”. This limits the balancing

to two cells (the highest two voltage cells). Again, refresh

the CB screen periodically to see the operation of the cell

balance code.

• Open the pack tab in the GUI and change some of the

settings for overvoltage, undervoltage or cell balance and

re-test. Remember to click on “Write” to send the new

parameters to the microcontroller.

1. If this is too long to wait, go to the “Pack Tab” and change the cell

balance on/off times. Setting 1s on and 1s off is the minimum

setting for cell balancing, but 2s on, 2s off is the recommended

minimum, only because an autoscan of 1s can cause confusion

due to the asynchronous nature of cell balance and autoscan.