ERVBR70 AND BR130

31.800.627.4499 INSTALLATION, OPERATION AND MAINTENANCE MANUAL RENEWAIRE.COM

BR70 AND BR130 INFO

CERTIFIED PERFORMANCE

SPECIFICATIONS

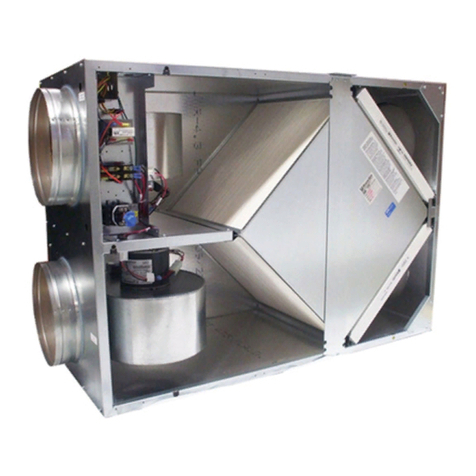

ENERGY EXCHANGE SYSTEM

Cross flow fixed-plate enthalpic heat exchanger

core; engineered, proprietary resin-media

composite. Moderates both temperature and

humidity extremes.

CERTIFIED PERFORMANCE

See Performance Report

ACCESS DOOR

Front panel opens to provide access to filters,

blowers, and heat exchanger. Snap latches and

hinges provided for easy service.

INSULATION

One inch foil-faced EPS foam throughout.

DUCT CONNECTIONS

Insulating double collars with 6" and 8" round

connections for flexible or rigid duct work.

MOUNTING OPTIONS

Unit may be mounted to duct or wall using integral

mounting flange with hanging bracket kit provided.

BLOWER/MOTOR

A single high efficiency PSC motor directly drives

two centrifugal blowers for quiet operation.

FILTERS

Cleanable polyester air filters for both exhaust and

fresh airstreams.

DEFROST

Passive frost-free design under most

residential conditions.

WARRANTY

Ten year limited warranty on heat exchange

core; five year limited warranty against defects

in material and workmanship on all other

components.

RENEWAIRE.COM 1.800.627.4499

164

OPTIONS & ACCESSORIES

HVI TESTED/CERTIFIED

PER CSA C439

Electrical Requirements Volts 120 Amps 3.3

Exhaust Air Transfer Ratio = 0.0% @ 0.2 in. wg (50 PA) and 2.0% @ 0.4 in. wg (100 Pa)

EV300 - Ventilation Performance

Ext. Static Pressure Net Supply Airflow Gross Airflow

Supply Exhaust

Pa in. wg L/S CFM L/S CFM L/S CFM

100 0.4 147 311 150 317 143 303

125 0.5 139 295 142 301 133 283

150 0.6 131 277 133 282 125 265

175 0.7 121 256 123 261 108 230

200 0.8 101 215 103 219 94 198

225 0.9 90 191 92 195 74 156

250 1.0 80 170 82 174 47 99

EV300 - Energy Performance

Supply

Temperature Net Airflow Average Power

Watts

Sensible Recovery

Efficiency %

Adjusted Sensible

Recovery

Efficiency %

Net Moisture

Transfer %

C° F° L/S CFM

Heating

0° 32° 139 297 315 67 73 54

Cooling Total

Recovery Efficiency %

Adjusted Total

Recovery Efficiency %

35° 95° 138 294 313 46 49

EV200 - Energy Performance

Supply

Temperature Net Airflow Average Power

Watts

Sensible Recovery

Efficiency %

Adjusted Sensible

Recovery

Efficiency %

Net Moisture

Transfer %

C° F° L/S CFM

Heating

0° 32° 85 181 157 78 84 62

Cooling Total

Recovery Efficiency %

Adjusted Total

Recovery Efficiency %

35° 95° 85 180 155 52 54

Electrical Requirements Volts 120 Amps 1.5

Exhaust Air Transfer Ratio = 3.0% @ 0.2 in. wg (50 PA) and 3.0% @ 0.4 in. wg (100 Pa)

EV200 - Ventilation Performance

Ext. Static Pressure Net Supply Airflow Gross Airflow

Supply Exhaust

Pa in. wg L/S CFM L/S CFM L/S CFM

25 0.1 97 207 100 213 109 232

50 0.2 90 192 93 199 104 221

75 0.3 88 186 90 192 101 216

100 0.4 83 176 85 181 96 204

125 0.5 79 168 81 173 88 187

150 0.6 70 149 72 154 76 162

175 0.7 57 122 59 126 68 145

EV240 - Energy Performance

Supply

Temperature Net Airflow Average Power

Watts

Sensible Recovery

Efficiency %

Adjusted Sensible

Recovery

Efficiency %

Net Moisture

Transfer %

C° F° L/S CFM

Heating

0° 32° 111 236 216 74 80 57

Cooling Total

Recovery Efficiency %

Adjusted Total

Recovery Efficiency %

35° 95° 108 229 213 53 56

Electrical Requirements Volts 120 Amps 3.3

Exhaust Air Transfer Ratio = 2.4% @ 0.2 in. wg (50 PA) and 2.3% @ 0.4 in. wg (100 Pa)

EV240 - Ventilation Performance

Ext. Static Pressure Net Supply Airflow Gross Airflow

Supply Exhaust

Pa in. wg L/S CFM L/S CFM L/S CFM

25 0.1 125 267 129 272 132 279

50 0.2 121 258 124 264 126 268

75 0.3 118 250 120 255 121 257

100 0.4 114 240 116 246 117 247

125 0.5 108 228 111 234 110 233

150 0.6 101 214 103 219 102 217

175 0.7 92 195 94 200 93 196

200 0.8 80 169 82 174 79 168

EV130 - Energy Performance

Supply

Temperature Net Airflow Average Power

Watts

Sensible Recovery

Efficiency %

Adjusted Sensible

Recovery

Efficiency %

Net Moisture

Transfer %

C° F° L/S CFM

Heating

0° 32° 61 130 102 71 75 53

Cooling Total

Recovery Efficiency %

Adjusted Total

Recovery Efficiency %

35° 95° 61 130 102 48 51

Electrical Requirements Volts 120 Amps 1.3

Exhaust Air Transfer Ratio = 2.0% @ 0.2 in. wg (50 PA) and 2.0% @ 0.4 in. wg (100 Pa)

EV130 - Ventilation Performance

Ext. Static Pressure Net Supply Airflow Gross Airflow

Supply Exhaust

Pa in. wg L/S CFM L/S CFM L/S CFM

25 0.1 77 165 79 168 79 168

50 0.2 72 153 73 156 73 156

75 0.3 64 137 66 140 66 140

100 0.4 59 126 61 129 61 129

125 0.5 49 104 50 106 50 106

150 0.6 37 79 38 81 38 81

EV90/GR90 - Energy Performance

Supply

Temperature Net Airflow Average

Power Watts

Sensible Recovery

Efficiency %

Adjusted Sensible

Recovery

Efficiency %

Net Moisture

Transfer %

C° F° L/S CFM

Heating

0° 32° 42 90 46 72 77 37

Cooling Total

Recovery Efficiency %

Adjusted Total

Recovery Efficiency %

35° 95° 42 90 44 46 48

Electrical Requirements Volts 120 Amps 0.35

Exhaust Air Transfer Ratio = 2.0% @ 0.2 in. wg (50 PA) and 2.0% @ 0.4 in. wg (100 Pa)

EV90/GR90 - Ventilation Performance

Ext. Static Pressure Net Supply Airflow Gross Airflow

Supply Exhaust

Pa in. wg L/S CFM L/S CFM L/S CFM

25 0.1 53 113 54 115 52 109

50 0.2 46 98 47 100 46 97

75 0.3 40 85 41 87 40 85

100 0.4 34 73 35 74 34 72

125 0.5 27 58 28 59 28 60

150 0.6 19 40 19 41 22 47

BR130 - Energy Performance

Supply

Temperature Net Airflow Average

Power Watts

Sensible Recovery

Efficiency %

Adjusted Sensible

Recovery

Efficiency %

Net Moisture

Transfer %

C° F° L/S CFM

Heating

0° 32° 58 124 121 72 78 55

Cooling Total

Recovery Efficiency %

Adjusted Total

Recovery Efficiency %

35° 95° 59 126 121 46 48

Electrical Requirements Volts 120 Amps 1.3

Exhaust Air Transfer Ratio = 1.6% @ 0.2 in. wg (50 PA) and 1.6% @ 0.4 in. wg (100 Pa)

BR130 - Ventilation Performance

Ext. Static Pressure Net Supply Airflow Gross Airflow

Supply Exhaust

Pa in. wg L/S CFM L/S CFM L/S CFM

25 0.1 70 148 71 151 75 159

50 0.2 66 141 67 143 69 147

75 0.3 62 132 63 134 64 135

100 0.4 53 113 54 115 56 119

125 0.5 44 94 45 96 47 99

150 0.6 32 69 33 70 29 62

175 0.7 24 52 25 53 21 45

EV90P - Energy Performance

Supply

Temperature Net Airflow Average Power

Watts

Sensible Recovery

Efficiency %

Adjusted Sensible

Recovery

Efficiency %

Net Moisture

Transfer %

C° F° L/S CFM

Heating

0° 32° 42 90 44 80 83 64

Cooling Total

Recovery Efficiency %

Adjusted Total

Recovery Efficiency %

35° 95° 42 90 44 63 71

Electrical Requirements Volts 120 Amps 0.35

Exhaust Air Transfer Ratio = 1.6% @ 0.2 in. wg (50 PA) and 2.0% @ 0.4 in. wg (100 PA)

EV90P - Ventilation Performance

Ext. Static Pressure Net Supply Airflow Gross Airflow

Supply Exhaust

Pa in. wg L/S CFM L/S CFM L/S CFM

25 0.1 51 108 52 110 52 110

50 0.2 47 99 48 101 47 100

75 0.3 41 87 42 89 42 89

100 0.4 35 73 36 75 36 76

125 0.5 26 56 27 57 27 58

150 0.6 20 42 20 42 21 44

165

FOR THE MOST COMPLETE AND CURRENT INFORMATION VISIT RENEWAIRE.COM

CERTIFICATIONS & PERFORMANCE

INDEPENDENTLY TESTED

PER CSA C439

Electrical Requirements Volts 120 Amps 1.0

Exhaust Air Transfer Ratio = 3.6% @ 0.2 in. wg (50 PA) and 3.4% @ 0.4 in. wg (100 Pa)

BR70 - Energy Performance

Supply

Temperature Net Airflow Average Power

Watts

Sensible Recovery

Efficiency %

Adjusted Sensible

Recovery

Efficiency %

Net Moisture

Transfer %

C° F° L/S CFM

Heating

0° 32° 32 69 94 66 75 53

Cooling Total

Recovery Efficiency %

Adjusted Total

Recovery Efficiency %

35° 95° 30 64 94 42 47

BR70 - Ventilation Performance

Ext. Static Pressure Net Supply Airflow Gross Airflow

Supply Exhaust

Pa in. wg L/S CFM L/S CFM L/S CFM

25 0.1 41 86 42 89 46 97

50 0.2 34 73 35 75 39 84

75 0.3 28 59 29 61 32 69

100 0.4 21 46 22 47 25 53

AHRI 1060

CERTIFIED PERFORMANCE

NOTE: SCFM = Standard Cubic Feet per Minute OACF = Outdoor Air Correction Factor EATR = Exhaust Air Transfer Ratio N/A = Not Applicable

Energy recovery component certified in accordance with AHRI Standard 1060-2013.

Actual performance in packaged equipment may vary.

Thermal Effectiveness Ratings at 0" Pressure Differential

Nominal Airflow Sensible Latent Total Net

Airflow

Net

Sensible

Net

Latent

Net

Total

750 Heating

CFM Cooling

70%

70%

52%

42%

64%

53%

750

CFM

70%

70%

52%

42%

64%

53%

563 Heating

CFM Cooling

74%

74%

59%

49%

69%

58%

563

CFM

74%

74%

59%

49%

69%

58%

Leakage Ratings

Pressure

Differential EATR OACF Purge Angle or

Setting

-1 in. H

2

0 1.0% 1.00 N/A

0 in. H

2

0 0.0% 1.02 N/A

1 in. H

2

0 0.0% 1.05 N/A

AHRI-1060 Certified Performance - Model Number L125-G5

Type Tilt Angle Nominal Airflow Pressure Drop

Plate N/A 100% - 750 SCFM

75% - 563 SCFM 0.65 in. H

2

0

Thermal Effectiveness Ratings at 0" Pressure Differential

Nominal Airflow Sensible Latent Total Net

Airflow

Net

Sensible

Net

Latent

Net

Total

500 Heating

CFM Cooling

70%

70%

52%

42%

64%

53%

500

CFM

70%

70%

52%

42%

64%

53%

375 Heating

CFM Cooling

74%

74%

59%

49%

69%

58%

375

CFM

74%

74%

59%

49%

69%

58%

Leakage Ratings

Pressure

Differential EATR OACF Purge Angle or

Setting

-1 in. H

2

0 1.0% 1.00 N/A

0 in. H

2

0 0.0% 1.02 N/A

1 in. H

2

0 0.0% 1.05 N/A

AHRI-1060 Certified Performance - Model Number L85-G5

Type Tilt Angle Nominal Airflow Pressure Drop

Plate N/A 100% - 500 SCFM

75% - 375 SCFM 0.65 in. H

2

0

Thermal Effectiveness Ratings at 0" Pressure Differential

Nominal Airflow Sensible Latent Total Net

Airflow

Net

Sensible

Net

Latent

Net

Total

350 Heating

CFM Cooling

70%

70%

52%

42%

64%

53%

350

CFM

70%

70%

52%

42%

64%

53%

263 Heating

CFM Cooling

74%

74%

59%

49%

69%

58%

263

CFM

74%

74%

59%

49%

69%

58%

Leakage Ratings

Pressure

Differential EATR OACF Purge Angle or

Setting

-1 in. H

2

0 1.0% 1.00 N/A

0 in. H

2

0 0.0% 1.02 N/A

1 in. H

2

0 0.0% 1.05 N/A

AHRI-1060 Certified Performance - Model Number L62-G5

Type Tilt Angle Nominal Airflow Pressure Drop

Plate N/A 100% - 350 SCFM

75% - 263 SCFM 0.65 in. H

2

0