#renishaw

© 2008–2023 Renishaw plc. All rights reserved. This document may not be copied or reproduced in whole or in part, or transferred to any other

media or language by any means, without the prior written permission of Renishaw.

RENISHAW®and the probe symbol are registered trade marks of Renishaw plc. Renishaw product names, designations and the mark

‘applyinnovation’ are trade marks of Renishaw plc or its subsidiaries. Other brand, product or company names are trade marks of their

respective owners.

WHILE CONSIDERABLE EFFORT WAS MADE TO VERIFY THE ACCURACY OF THIS DOCUMENT AT PUBLICATION, ALL WARRANTIES,

CONDITIONS, REPRESENTATIONS AND LIABILITY, HOWSOEVER ARISING, ARE EXCLUDED TO THE EXTENT PERMITTED BY LAW.

RENISHAW RESERVES THE RIGHT TO MAKE CHANGES TO THIS DOCUMENT AND TO THE EQUIPMENT, AND/OR SOFTWARE AND

THE SPECIFICATION DESCRIBED HEREIN WITHOUT OBLIGATION TO PROVIDE NOTICE OF SUCH CHANGES.

Renishaw plc. Registered in England and Wales. Company no: 1106260. Registered office: New Mills, Wotton-under-Edge, Glos, GL12 8JR, UK.

www.renishaw.com/TP200

+44 (0) 1453 524524 uk@renishaw.com

Issued: 07.2023

Part no.: H-1000-5166-02-A

6 Maintenance

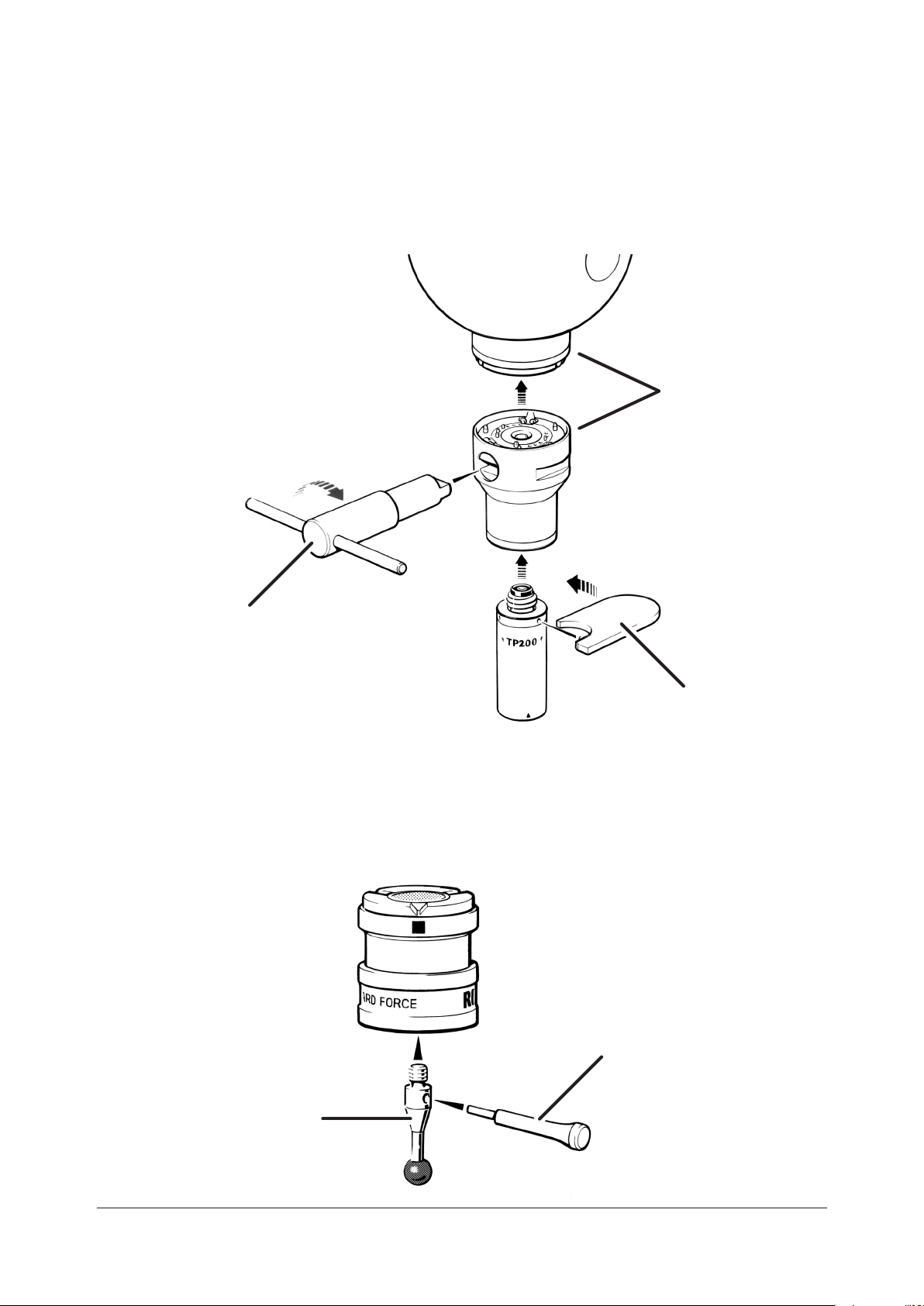

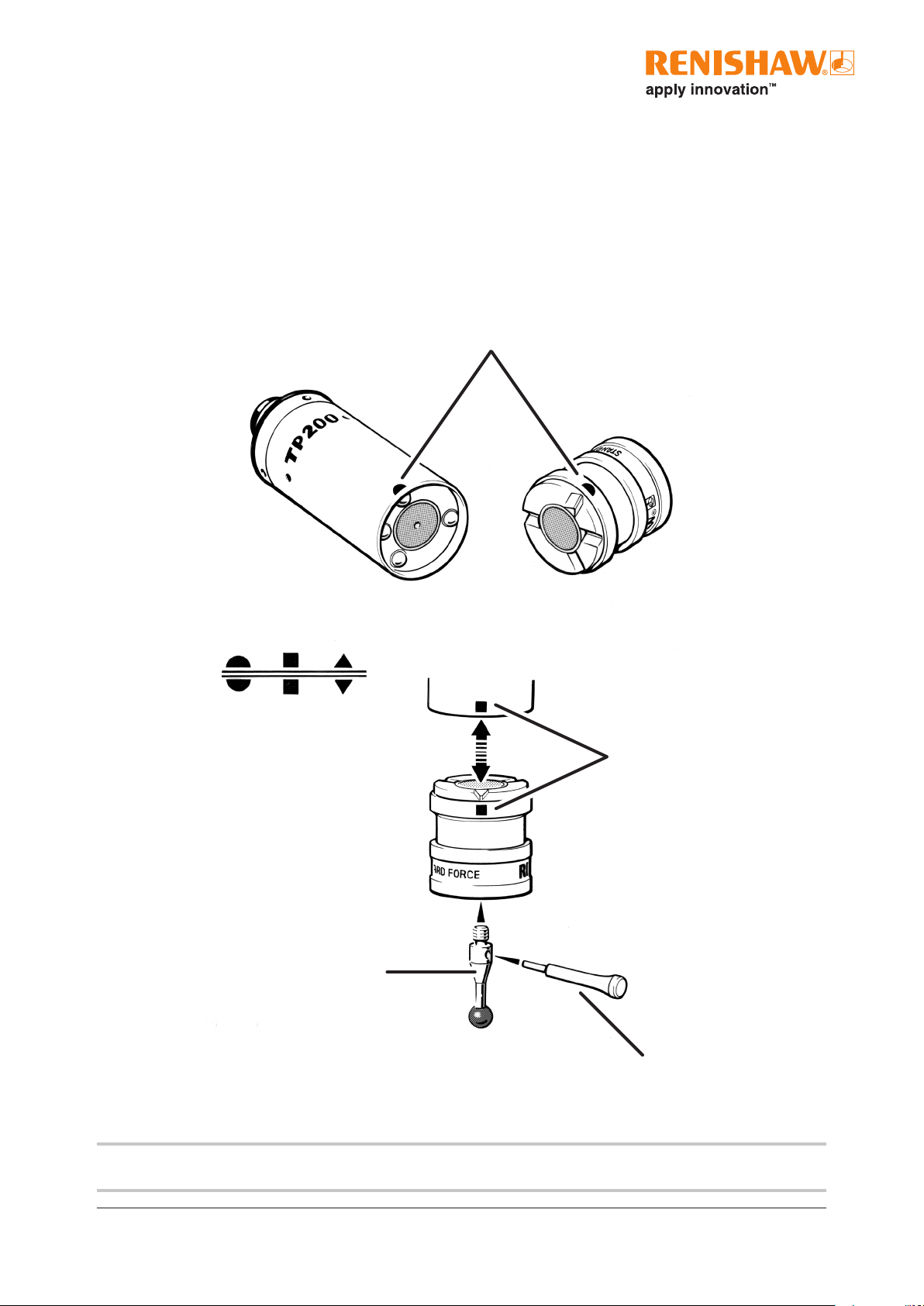

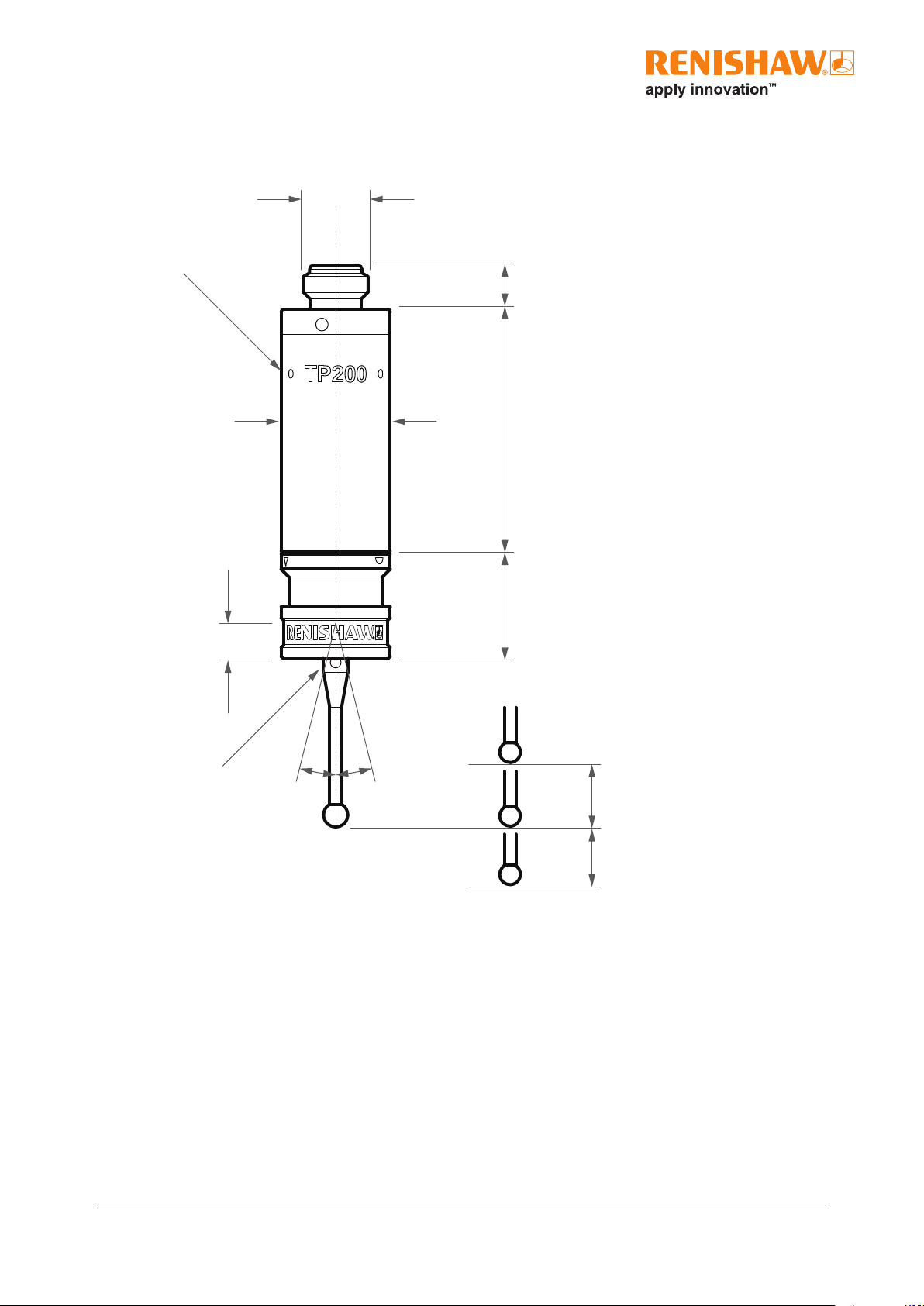

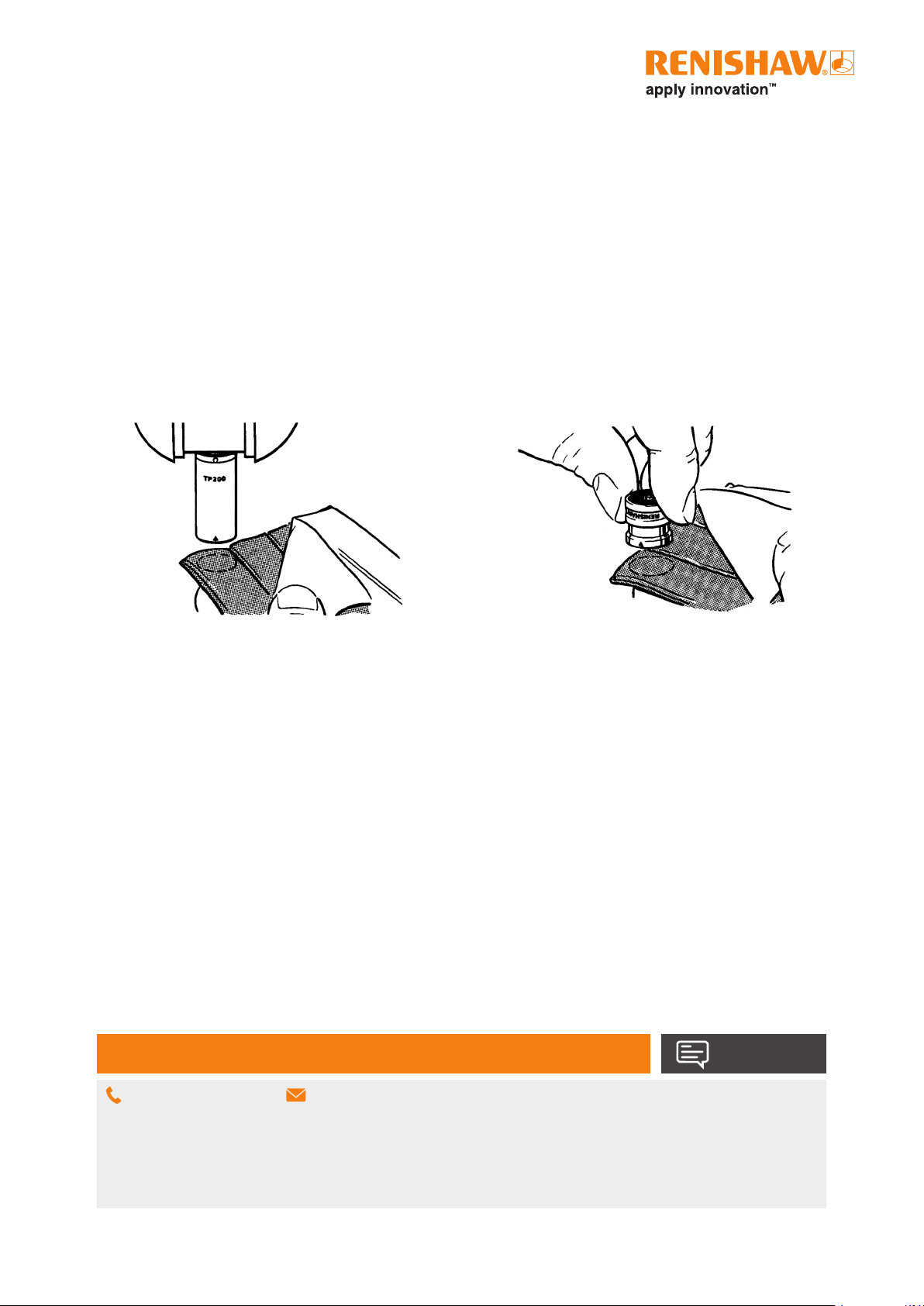

The kinematic coupling mechanism, connecting the probe body to the stylus module, incorporates precision ball / V groove seatings.

The coupling mechanism has been tested in a wide range of environments and is highly tolerant of non-metallic dust, but regular

inspection and cleaning with the CK200 material (supplied) is recommended to ensure continued high performance. Instructions for

use are included with the cleaning material (Renishaw part number A-1085-0016).

The user should determine the frequency of cleaning according to the conditions of use.

Stylus balls, threads and mating faces should be cleaned with a proprietary cleaning cloth or solvent.

Stylus modules that are not in use should be stored in spare ports in the SCR200 rack or in their transport boxes.

Before cleaning the probe body, please ensure either the power is off or that the probe body is removed from the probe head.

After cleaning the probe body and module re-attach the module following the instructions in the attaching stylus module section

above.