01

Important Safety Instructions

Please save these instructions.

This manual contains important installation, operation, and maintenance instructions for the

Smart Lithium Iron Phosphate Battery. Please observe these instructions and keep them

located near the battery for further reference. The following symbols are used throughout

the manual to indicate potentially dangerous conditions or important safety information.

Indicates a potentially dangerous condition. Use extreme caution when

performing this task.

Indicates a critical procedure for the safe and proper installation and

operation of the battery.

Indicates a procedure or function that is important to the safe and proper

installation and operation of the battery.

Force majeure including fire, typhoon, flood, earthquake, war, and terrorism.

Intentional or accidental misuse, abuse, neglect or improper maintenance, and use under

abnormal conditions.

Improper installation, improper operation, and malfunction of a peripheral device.

Contamination with hazardous substances, diseases, vermin, or radiation.

Alterations to the product without express written consent from the manufacturer.

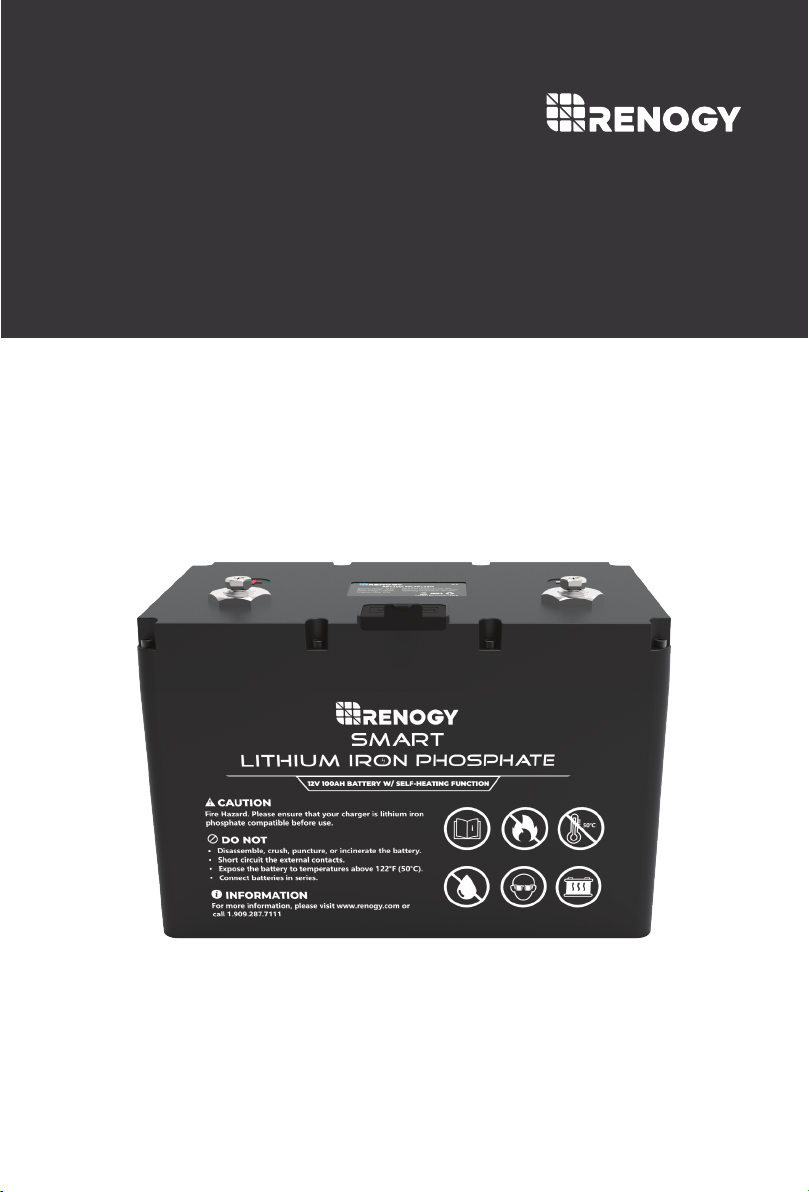

Please keep the battery away from water, heat sources, sparks, and hazardous chemicals.

DO NOT puncture, drop, crush, burn, penetrate, shake, or strike the battery.

DO NOT open, dismantle, or modify the battery.

DO NOT touch any terminals or connectors.

DO NOT touch the exposed electrolyte or powder if the battery casing is damaged.

Uncovered electrolyte or powder that has contacted the skin or eyes MUST be flushed out

with plenty of clean water immediately. Seek medical attention afterwards.

The manufacturer accepts no liability for any damage caused by:

Disclaimer

General Safety Information