4

introduction

Thank you for purchasing Renova’s moviroll.

We also thank you for the preference you have reserved for this innovative product. We are certain it will

satisfy you with its technologically advanced solutions, its in-line and elegant design and its professional

quality.

In this manual you will find our instructions for a proper use of this product and the necessary technical

information, as well as our advices, to ensure excellent performance over time.

Please take the time to read and understand the instructions completely before the installation and use of

this product. In the event of a possible breakdown of this product, the operator should understand the

manufacturer’s instructions and be aware of the dangers, before any check intervention or recourse of

Renova’s technical assistance.

The warranty does not apply in cases which occur as a result of the Customer’s incorrect use, improper

application, negligence (including but not limited to improper maintenance and storage), accidents,

improper installation, modifications (included but not limited to the use of non-original parts or accessories

not authorized by Renova), improper adjustment or repair. All parts subject to normal wear are excluded

from the guarantee.

foreword

moviroll is a roll pusher that allows the operator to effortlessly handle cylindrical loads on a flat surface.

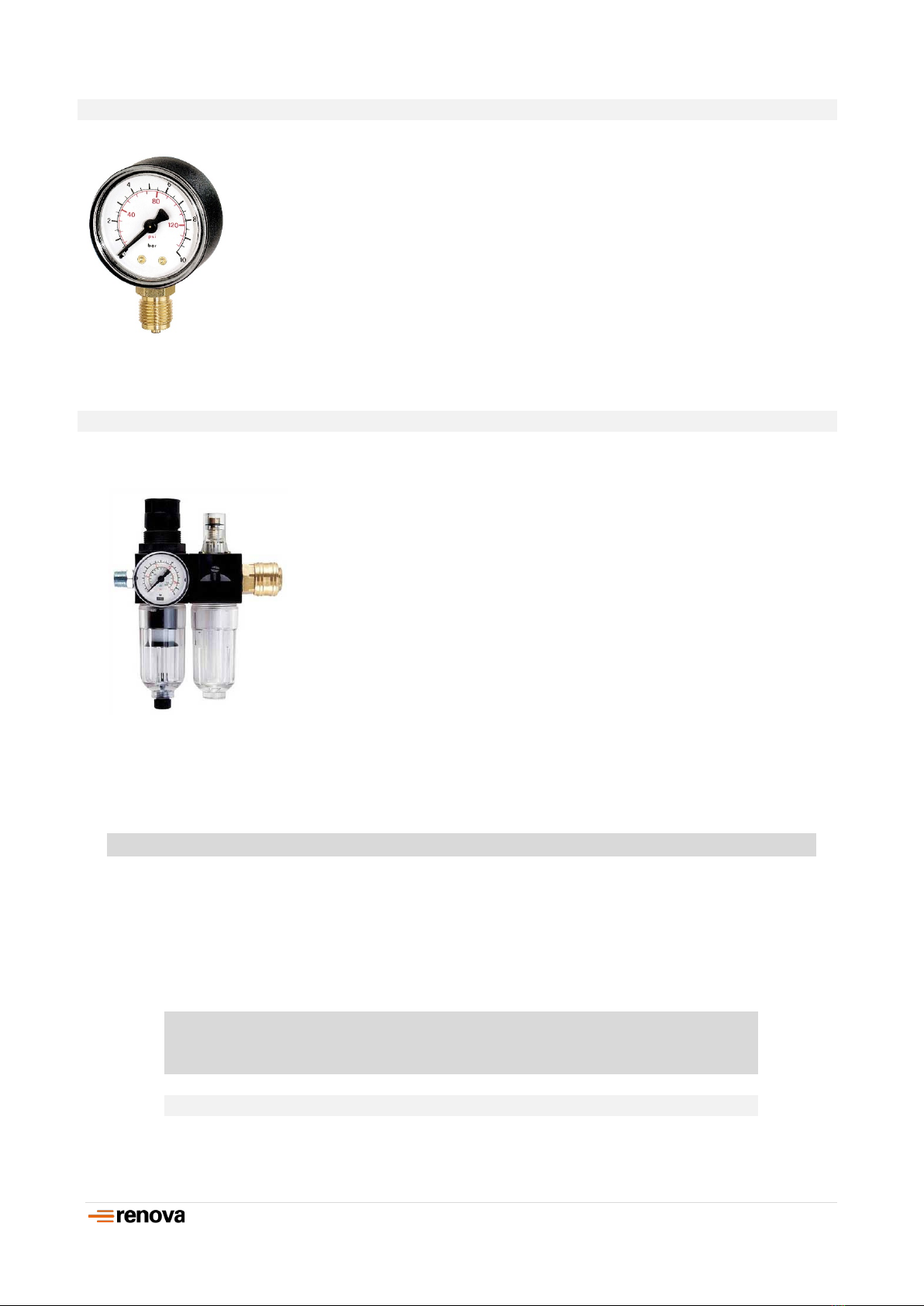

The machine is driven by a pneumatic gear motor that is activated by pressurized and lubricated air at

6 bar.

The activation of this gear motor allows the transmission of the circular motion to a pyramidal system

composed of three rubber rollers.

Thanks to the chain drive, the motion is transferred from the pinion fit to the gear motor to the pinion fit

to the drive roller. When the drive roller is touching the roll, it has been compressed by the roll weight

against the driving rollers. In this way the continuous and effortless handling of the roll is guaranteed but

only when the load is applied.

In the case that the device is activated without the load, the drive roller will run free, since the springs that

hold it detached from the drive rollers would not be compressed.