Dear customer,

Thank you for purchasing Renova’s MRE L / MRE LP / MRE LPT moviroll –battery roll pusher.

We also thank you for the preference you have reserved for this innovative product. We are certain it will satisfy you

with its technologically advanced solutions, its in-line and elegant design and its professional quality.

In this manual you will find our instructions for a proper use of this product and the necessary technical information,

as well as our advices, to ensure excellent performance over time.

All information contained in this manual have been collected respecting the rules in force, the current state of

knowledge of design and construction, our knowledge and our many years of experience.

The instruction manual was translated with all due care and attention. However, we do not accept liability for any

translation errors. The Italian version of this instruction manual is definitive.

The warranty does not apply in cases which occur as a result of the Customer’s violation of advice concerting

operation, incorrect use, improper application, negligence (including but not limited to improper maintenance and

storage), accidents, improper installation, modifications (included but not limited to the use of non-original parts or

accessories not authorized by Renova), improper adjustment or repair. All parts subject to normal wear are excluded

from the guarantee.

CAREFULLY READ THE INSTRUCTIONS AND WARNINGS IN THIS MANUAL AND KEEP THEM FOR FURTHER

REFERENCE FOR ENTIRE PRODUCT LIFE. THEY SUPPLY IMPORTANT INSTRUCTIONS REGARDING OPERATIONS AND

SAFETY FOR INSTALLING, USING AND MAINTAINING THE PRODUCT.

PLEASE TAKE THE TIME TO READ AND UNDERSTAND THE INSTRUCTIONS COMPLETELY BEFORE THE INSTALLATION

AND USE OF THIS PRODUCT.

IN THE EVENT OF A POSSIBLE BREAKDOWN OF THE PRODUCT, THE OPERATOR SHOULD UNDERSTAND THE

MANUFACTURER’S INSTRUCTIONS AND BE AWARE OF THE DANGERS, BEFORE ANY CHECK INTERVENTION OR

RECOURSE OF RENOVA’S TECHNICAL ASSISTANCE.

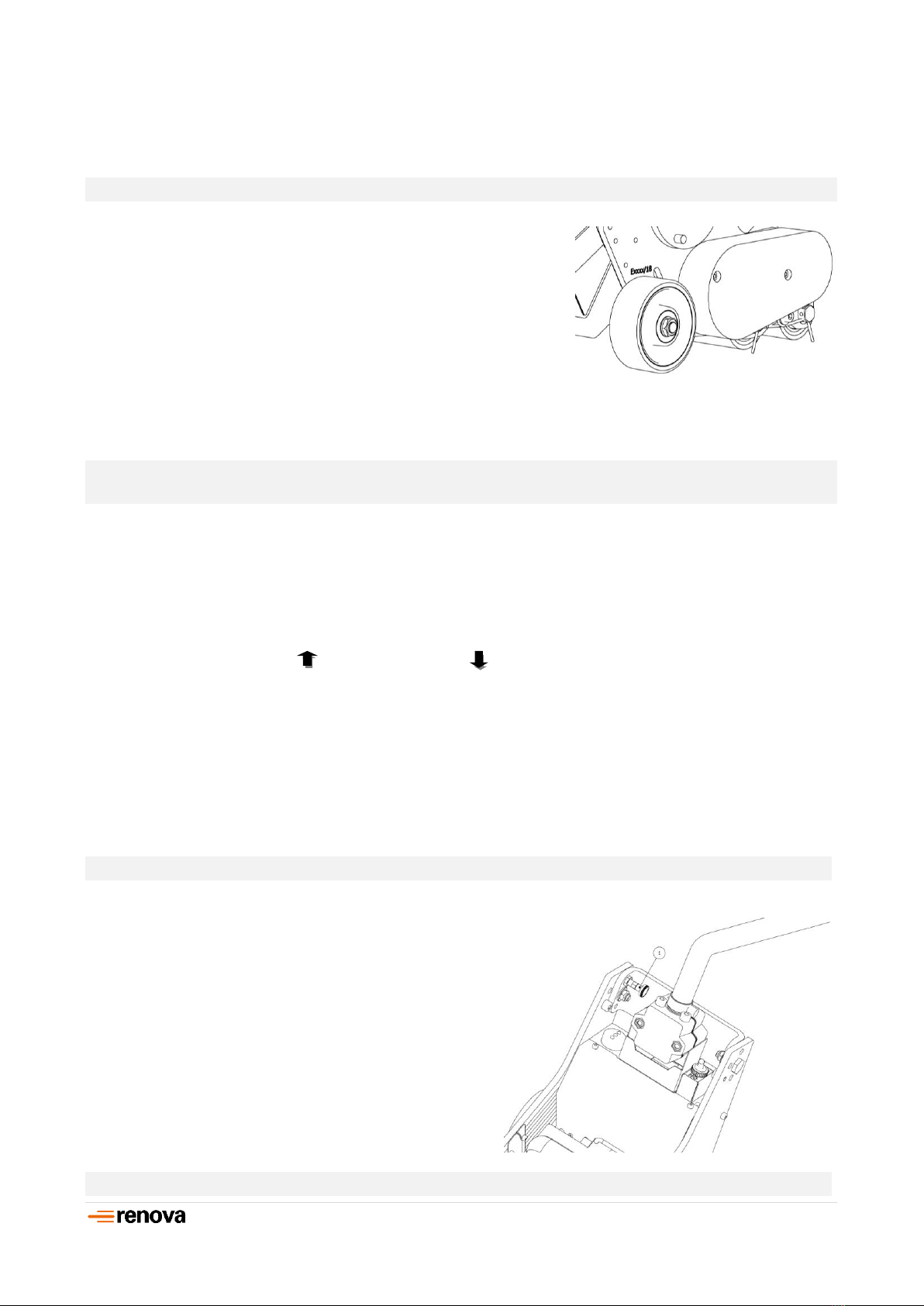

▪MRE L / MRE LP / MRE LPT moviroll is exclusively designed to move cylindrical loads as paper and corrugated

rolls, wood and steel rolls, and vehicles.

▪MRE L / MRE LP / MRE LPT moviroll must not be used to brake heavy loads which run toward the appliance.

▪The work place must be kept proper of whatever object should be between the machine and the object to move.

Any object in between that could create a somersault, a sliding or a fall must be kept away.

▪The operator must always be aware that nothing or no one is in the way of the object to be displaced and that no

one could be endangered by the moving object.

▪Certain fundamental rules must be respected when using any kind of electrical appliance. More specifically:

- do not leave the appliance exposed to the weather (rain, sun, etc.)

- do not use the appliance next to flammable material

- do not let children or incapable persons use the appliance without supervision

▪A hearing protection must always be used.