5

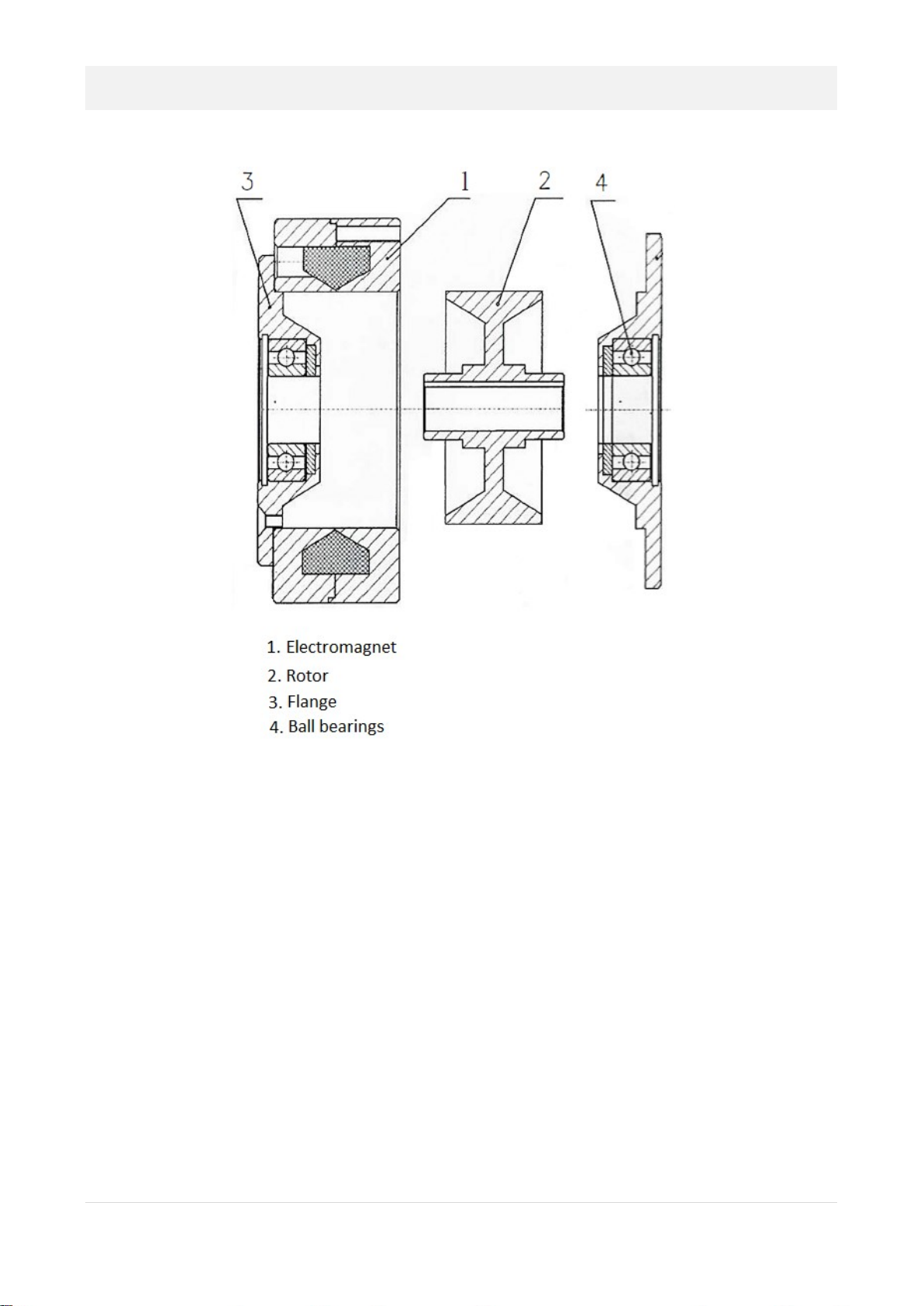

description

The PWX series electromagnetic powder brakes guarantee perfect torque adjustment and stability

over a wide speed range. The torque is produced by a special magnetic powder whose viscosity

varies according to the magnetic field generated by modulating the coil supply current. This

functional feature allows to design transmissions in which it is possible to easily adjust and

program the braking (brake) or drag (clutch) torque according to the user's needs and in a wide

range of use, from the minimum residual torque value: Mr (residual torque Mr <= 1% Mn), up to

the rated torque Mn of the brake/clutch (see Table). These clutches (brakes) can work with

continuous slip at precise defined and stable torque values, determined by the level of

electromagnetic excitation, provided that the heat dissipation is acceptable within the range

specified in the table divided by size and version.

In order to transfer the torque, therefore, a slipping condition is not necessary between the

brake/clutch input and output elements and, if the required torque does not exceed the maximum

torque for which the brake is powered, a torque transmission with rotation will occur.

synchronous between the brake / clutch input and output elements. Conversely, if the torque load

exceeds the excitation torque level, the slip will occur in an absolutely regular way, transmitting

only the set torque value. For all working modes, the static and dynamic torque coefficients are

practically identical. The output torque is independent of the speed or slip speed. The

characteristics of the powder are not sensitive to the increase in temperature in the workplace

and the clutch always has the characteristic that the torque transferred is directly proportional to

the supply current.

To adjust the braking torque Renova recommends using the ALPWX-5A module. The set torque is

maintained with an accuracy of 5%, regardless of the number of revolutions or slippage between

the brake body and the rotor. The operating rpm range is as follows:

50 - 3.000 [min-1] for brakes,

50 - 1.500 [min-1] for clutches.

ATTENTION: For clutches and brakes to work properly, their axis of rotation must

be horizontal.