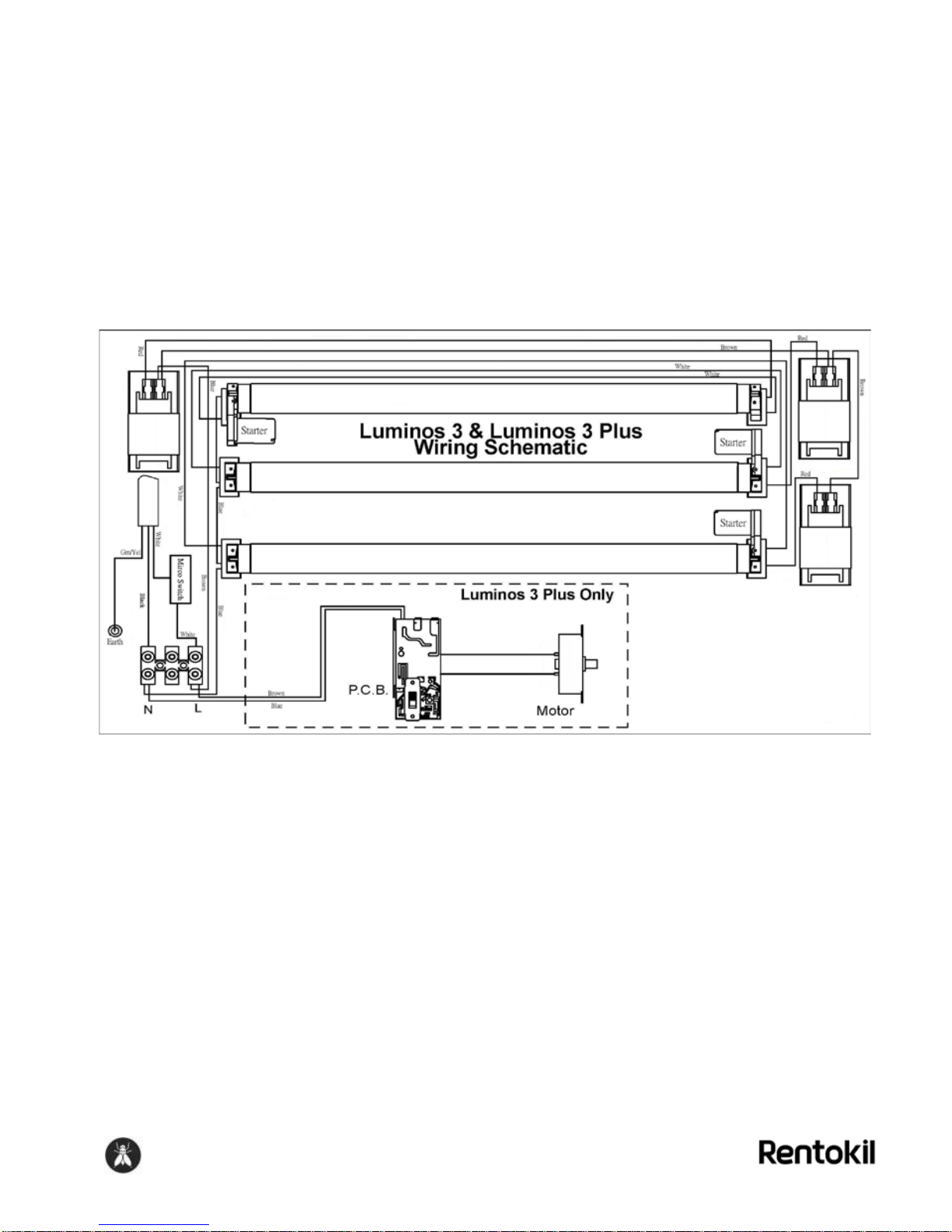

TYPE OF UNIT

The electronic Flying Insect Control

System (FICS) does not use high voltage

grids. Instead flying insects are captured

on a replaceable adhesive film. Insects

are attracted to the unit by 3 x 15 watt

ultra-violet lamps and the film prevents

their escape.

UNPACKING THE UNIT

Each unit is carefully packed before

leaving the production factory to ensure it

reaches you in perfect working order.

Please be sure to remove all packing

from the unit before installation and

check the unit for any transit damage.

LOCATIONS

The attraction of the unit to flying insects

is partly dependent on the intensity of the

competing daylight or artificial light. The

correct location of the unit is most

important in order to achieve the

maximum efficiency. Where possible,

follow these guidelines:

1. The unit can be mounted on any

suitable wall except for those

locations where the sight of captured

insects would be undesirable. In

these situations the unit should be

mounted above head height.

Wherever the unit is placed there

should be enough clearance in front

and above (at least 60mm) the front

cover to allow it to open up for ease

of servicing.

2. Place the unit as far as possible from

windows, to minimize the competition

from daylight.

3. DO NOT place the unit directly over

sources of heat since these may

damage the cable installation.

4. DO NOT position directly over areas

where food is prepared or uncovered

food is stored.

5. CAUTION, Risk of UV exposure,

keep a safe distance of 1,19 feet

from this unit whilst illuminated.

Unlike high voltage units, this system

may be placed in food production areas,

providing easy access is possible and

that sheathed shatterproof tubes are

fitted.

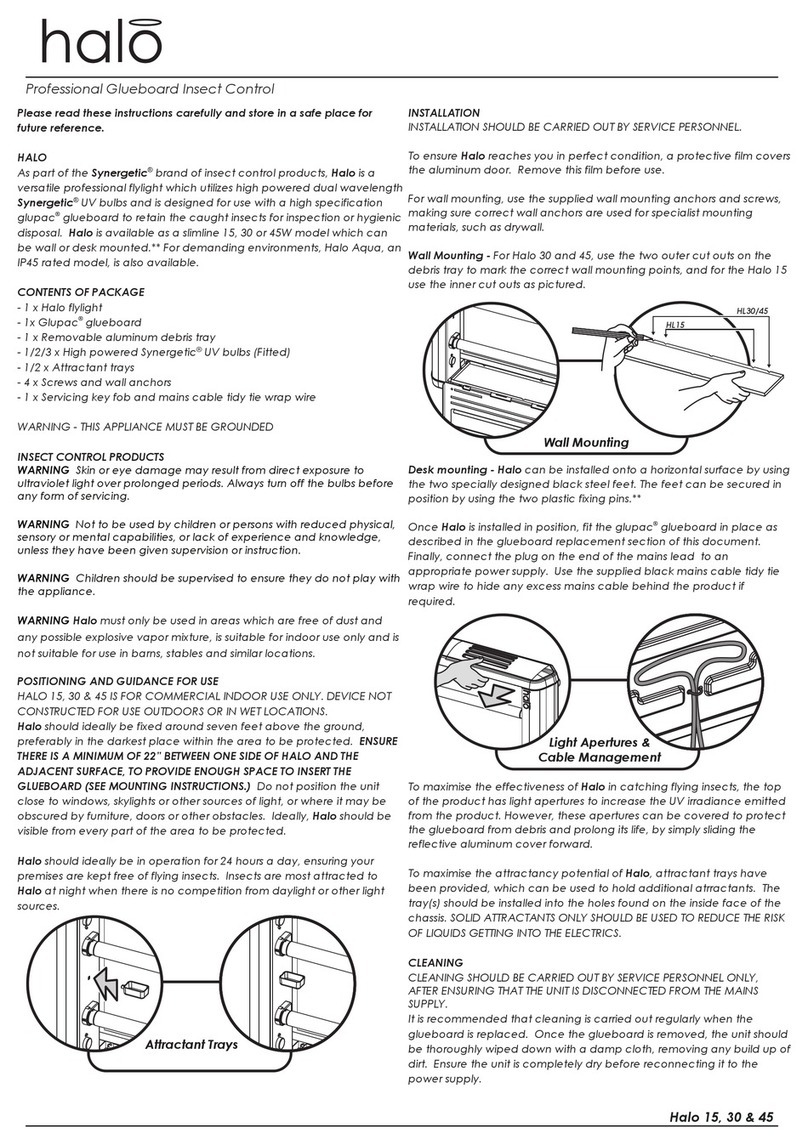

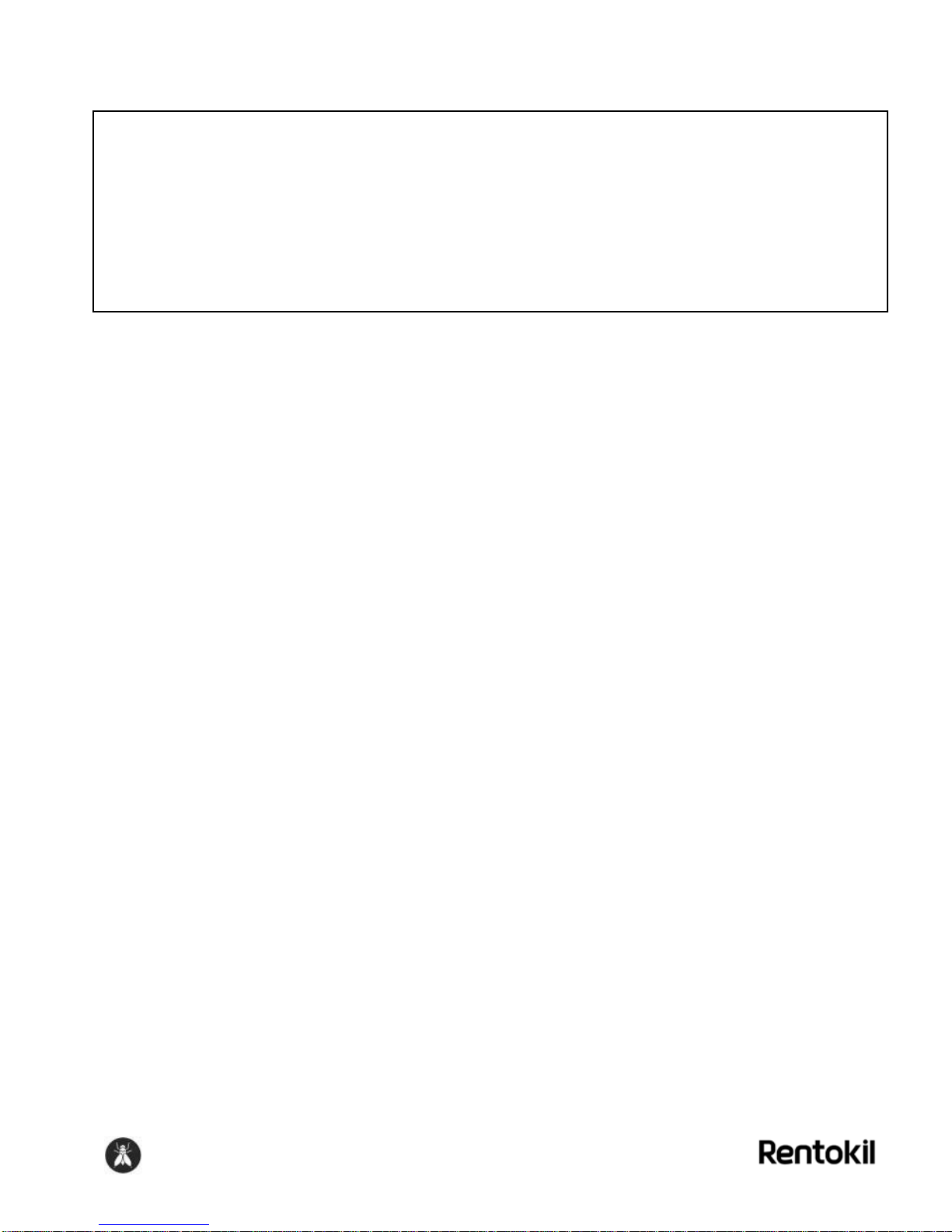

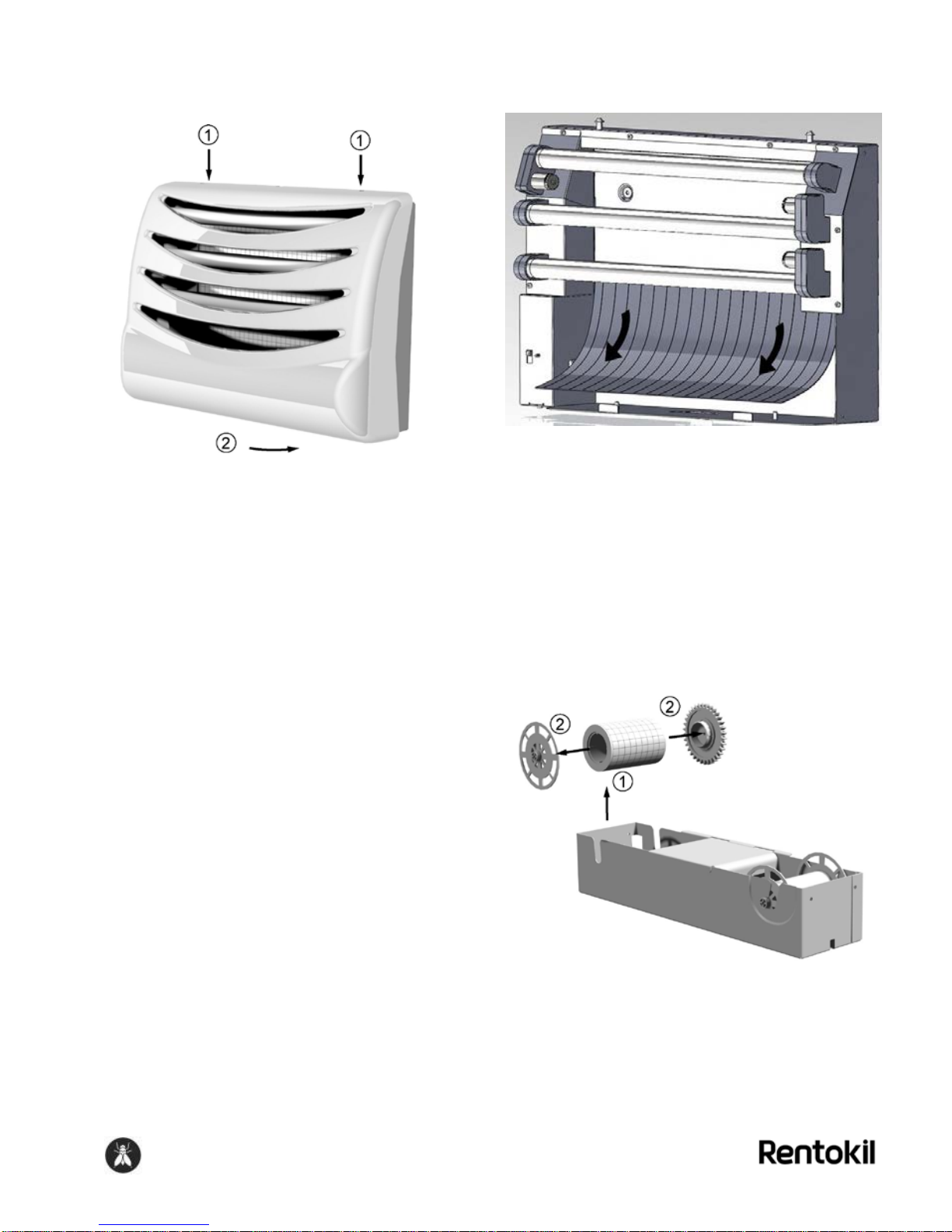

ASSEMBLY & INSTALLATION

Luminos 3 Plus is a wall-mounted unit.

To fix to the wall first unclip the cover

from the backplate and lift off the catch

tray.

Locate the unit on the wall in the selected

position, making sure that the top edge is

horizontal, and that there is an

unobstructed distance of at least 200mm

(8”) above the top fixing hole centers,

then mark the wall and drill holes for

screw plugs. Number 8 or 10 screws, at

least 40 mm (1½”) long are

recommended. Insert four plugs into the

holes and screw the unit firmly to the

wall. Do not over-tighten the screws.

Refit the catch tray and cover.