REOVIB MFS 368

Operating instructions

2

Table of contents

Safety instructions for the user..................................................................................................................... 3

Declaration of Conformity ............................................................................................................................. 6

Changes / Copyright..................................................................................................................................... 6

1.0 General................................................................................................................................................... 7

2.0 Function.................................................................................................................................................. 7

2.1 Track control ....................................................................................................................................... 8

2.2 Operation with two speeds (2

nd

setpoint for coarse/fine switching).................................................... 8

2.3 Control inputs and outputs.................................................................................................................. 9

2.3.1 Enable input..................................................................................................................................9

2.3.2 Sensor input for track control .......................................................................................................9

2.3.3 External setpoint........................................................................................................................... 9

2.3.4 Control output status relay ........................................................................................................... 9

2.3.5 Control output 24 VDC Timeout (IP54)........................................................................................9

2.3.6 Ready relay .................................................................................................................................. 9

2.3.7 Control output 24 VDC Valve (IP54) ............................................................................................9

2.3.8 Thermal switch ............................................................................................................................. 9

2.4 Touch panel ......................................................................................................................................10

3.0 Structure ............................................................................................................................................... 11

3.1 IP54...................................................................................................................................................11

3.2 IP20...................................................................................................................................................11

4.0 Technical data ......................................................................................................................................11

4.1 Load supply requirements ....................................................................................................................12

4.2 Terminal details ....................................................................................................................................12

4.3 Temperature of protective housing.......................................................................................................12

4.4 Coolant type..........................................................................................................................................12

4.5 Current consumption ............................................................................................................................12

4.6 Warning signs.......................................................................................................................................12

5.0 Ordering code (Standard units) ............................................................................................................13

6.0 Possible settings...................................................................................................................................14

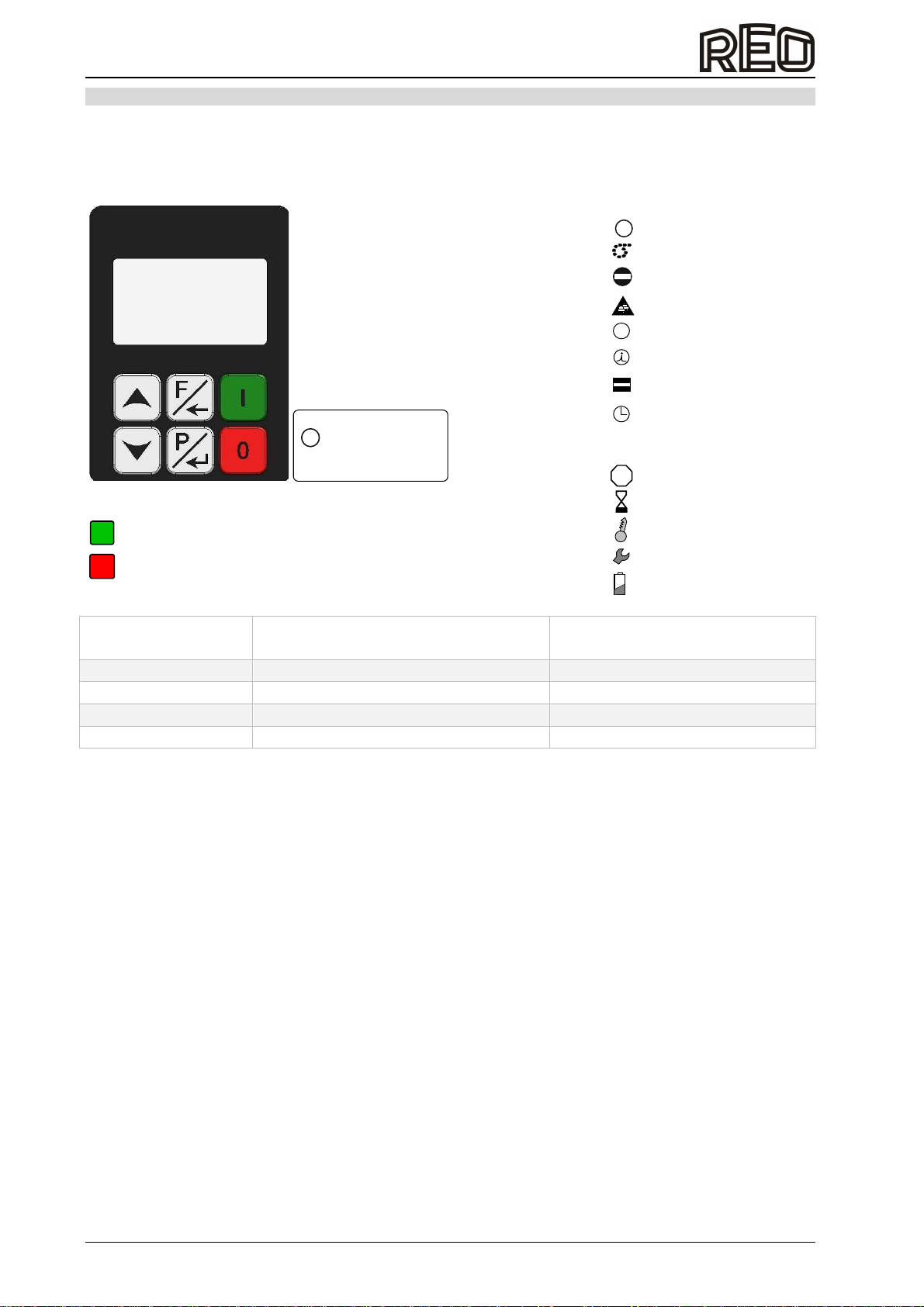

7.0 Operating elements ..............................................................................................................................16

7.1 Setting behaviour..............................................................................................................................16

7.1.1 Parameter setting example............................................................................................................17

7.1.2 External setpoint example .................................................................................................................17

8.0 Commissioning.....................................................................................................................................18

8.1 Preparatory measures.......................................................................................................................18

8.2 Operating frequency of the feeder coils............................................................................................18

8.3 Measurement of output voltage and output current..........................................................................18

9.0 Settings.................................................................................................................................................19

9.1 Notes on controller mode..............................................................................................................19

9.2 Mounting the accelerometer..........................................................................................................19

9.3 Correlation between acceleration and vibration amplitude...........................................................21

9.4 Determining the resonant frequency.............................................................................................21

9.5 Commissioning the control unit in control mode ...........................................................................22

10.0 Troubleshooting ..............................................................................................................................23

11.0 Housing version connection ...............................................................................................................24

12.0 Connection of control cabinet version ................................................................................................25

13.0 Dimension drawing.............................................................................................................................27

14.0 Assembly instruction...........................................................................................................................30

A 1.0 Accessories / Options .......................................................................................................................31