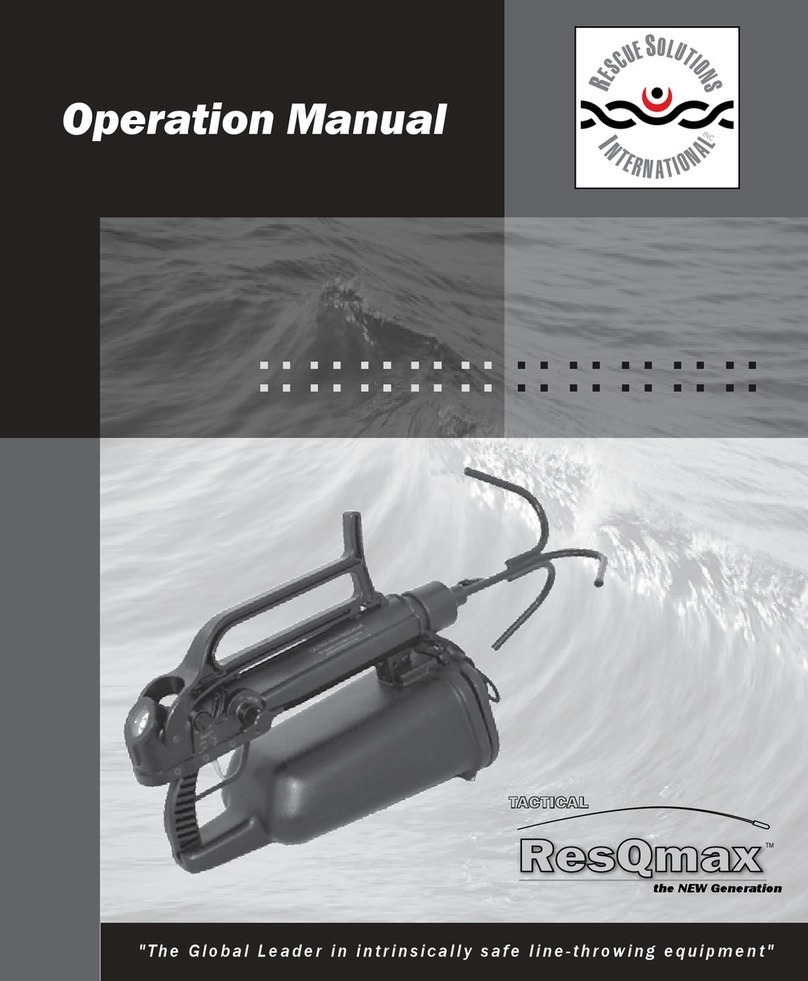

Tactical ResQmax Operation ManualTactical ResQmax Operation Manual

2

Service

Any service or maintenance other than items described in this manual must be performed by a technician

certified by the Manufacturer to perform such work. It is the purchaser’s responsibility to register the product

with the Manufacturer. Failure to complete warranty registration will void the warranty. For your convenience

a Service & Maintenance ecord is provided on page 38 of this manual. It is the purchaser’s responsibility to

enter the date of purchase on the Service & Maintenance ecord, and to insure that servicing is done in

accordance with the Manufacturer’s recommendations. escue Solutions International, Inc. offers F EE technical

© 2002 escue Solutions International, Inc.

1210-B Keystone Way

Vista, CA 92081 USA

760.727.8998 760.727.8688 fax

http://www.resqmax.com

Warnings

This equipment is intended to be used by professionals trained in the use of this equipment. Misuse of

this equipment may cause bodily injury or death. Manufacturer disclaims all liability resulting from the

use of this equipment in any manner other than that prescribed by the manufacturer.

The Tactical esQmax is extremely powerful and propels a projectile at high speed. It is NOT a firearm,

but the same precautions should be used. If misused, this equipment could cause serious bodily injury or

death. Handle all components with the appropriate care.

DO NOT deploy the Tactical esQmax directly at any person or property. When testing or training

with the Tactical esQmax, make sure that no persons or property are in the vicinity of the target.

The Tactical esQmax requires proper training and servicing. If you are not familiar with this equipment

or unwilling to follow the recommendations as outlined in this Operation Manual, then you should not

operate this equipment. The user must follow recommended servicing and maintenance guidelines to

ensure the long-term integrity and safety of the Tactical esQmax.

Some optional grappling hooks offered are for use to establish a line only – or for recover of mooring

lines - and should not be used for the support of a human being. Only grappling hooks certified for

climbing by the manufacturer should be used for the support of a human being.

Loads imposed on grappling hooks should never exceed the design loads. Any grappling hooks must be

removed from service if any signs of damage or deformity are visible.

It is the responsibility of the purchaser of any grappling hooks to establish a program which provides for

regular examination of each grappling hook for deformation or invisible fractures using a magnetic

particle test or other similar test. Any grappling hook which shows hidden fractures as a result of such

a test should be immediately removed from service. The frequency of this examination is at the discretion

of the purchaser, and should be based upon the use of the grappling hook. It is the purchaser’s responsibility

to insure that all grappling hooks are maintained in a manner which makes them suitable for their

intended use.

If you are uncertain about the proper usage, care, maintenance or any other aspect of this equipment,

call escue Solutions International, Inc. directly at 800.709.5018 or 760.727.8998 or by email at

Note:

See Disclaimer, page

35, for an Important

Note.

35

escue Solutions International Inc. warrants to the original owner, that if used, maintained and

stored according to the manufacturer’s recommendations, that the Tactical esQmax is free

from defects in material and workmanship for twelve (12) months from the date of the sale.

THIS WA ANTY IS LIMITED TO THE EPAI AND EPLACEMENT OF PA TS AS NECESSA Y,

AND ANY NECESSA Y LABO AND SE VICES EQUI ED TO EPAI O EPLACE ANY

PA TS TO ENDE THE DEVICE F EE OF DEFECTS. THE SOLE OBLIGATION OF ESCUE

SOLUTIONS INTE NATIONAL, INC. SHALL BE THE EPAI O EPLACEMENT OF THE

Tactical esQmax AND UNDE NO CI CUMSTANCES SHALL ESCUE SOLUTIONS

INTE NATIONAL, INC., ITS AGENTS, SUCCESSO S, O ASSIGNS, BE LIABLE FO ANY

DI ECT, CONSEQUENTIAL, O OTHE DAMAGES A ISING OUT OF ANY CLAIMED

DEFECT IN THE DEVICE O THE METHOD OF ITS USE. THIS WA ANTY IS IN LIEU OF

ALL OTHE WA ANTIES, EXP ESS O IMPLIED, WHETHE ELATING TO FITNESS,

ME CHANTABILITY, O OTHE WISE.

Except as to the express warranty set forth above, the manufacturer disclaims any and all

warranties and representations relating to the product. This limited warranty shall be governed

by the laws of the State of California.

If you have a problem with your Tactical esQmax, call 760-727-8998 within 90 days of discovery

of the problem. You will be given instructions on where to send your Tactical esQmax for repair

or replacement. If the problem is covered by this warranty, escue Solutions International, Inc.

will repair or replace your Tactical esQmax, or otherwise notify you, within 30 days of receipt

of the Tactical esQmax. Any actions for breach of warranty or breach of contract must be

commenced within one year from the date of discovery of the breach.

LimitedWarranty

Disclaimer

escue Solutions International, Inc. ( SI) has developed the Tactial esQmax and all accessories in

response to strong demand expressed by military, police and special forces teams worldwide. This

product was created to fill an existing need as indicated by personnel and organizations whose

members and employees knowingly and consciously are routinely engaged in very high risk and

often life-threatening activities in the ordinary course of the performance of their duties.

SI manufactures this equipment for use by, and at the discretion of, professionals aware of the

risks associated with the use of this type of equipment, and who are properly trained in its use.

This manual is intended only to educate the user in various aspects of this specific equipment.

This manual does not undertake to teach, train, encourage or condone any activities that may be

associated with the use of this equipment. No equipment, brochure, manual or other materials

produced by SI, nor the offer for sale or the sale itself of this equipment, is intended to induce

any individual or organization to put personnel at personal risk.

escue Solutions International, Inc. has no control over the training in the use of this equipment,

the maintenance and servicing of this equipment, or the conditions under which this equipment

is used. escue Solutions International, Inc. disclaims any and all responsibility for any liability

arising out of the use of this equipment, however caused.