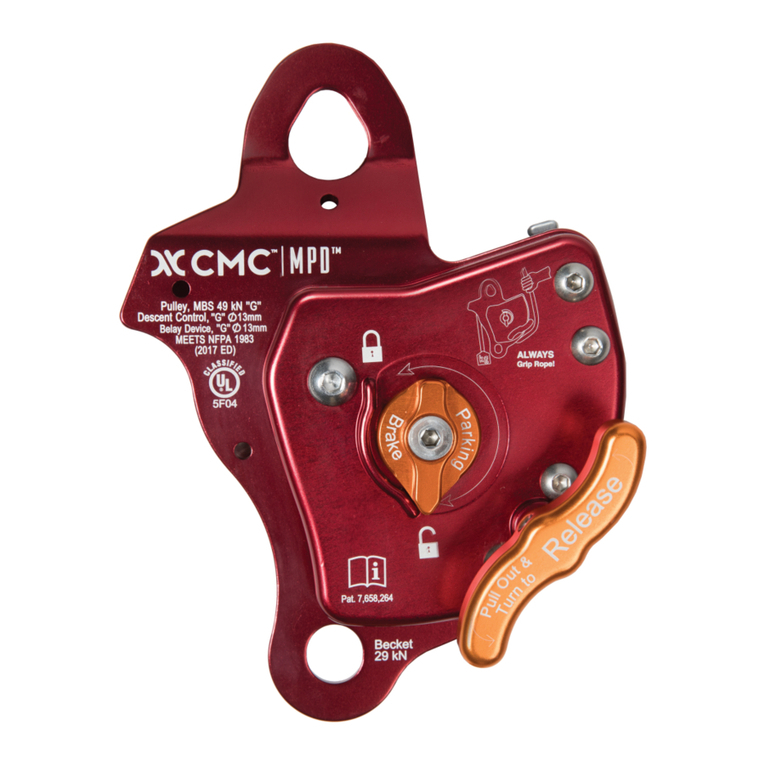

• RATED FOR TECHNICAL USE (T) Ø 9.5mm - 13mm, MBS 13.5 kN (3,034 lbf)

• RATED FOR GENERAL USE (G) Ø 13mm, MBS 22 kN (4,946 lbf)

5F04

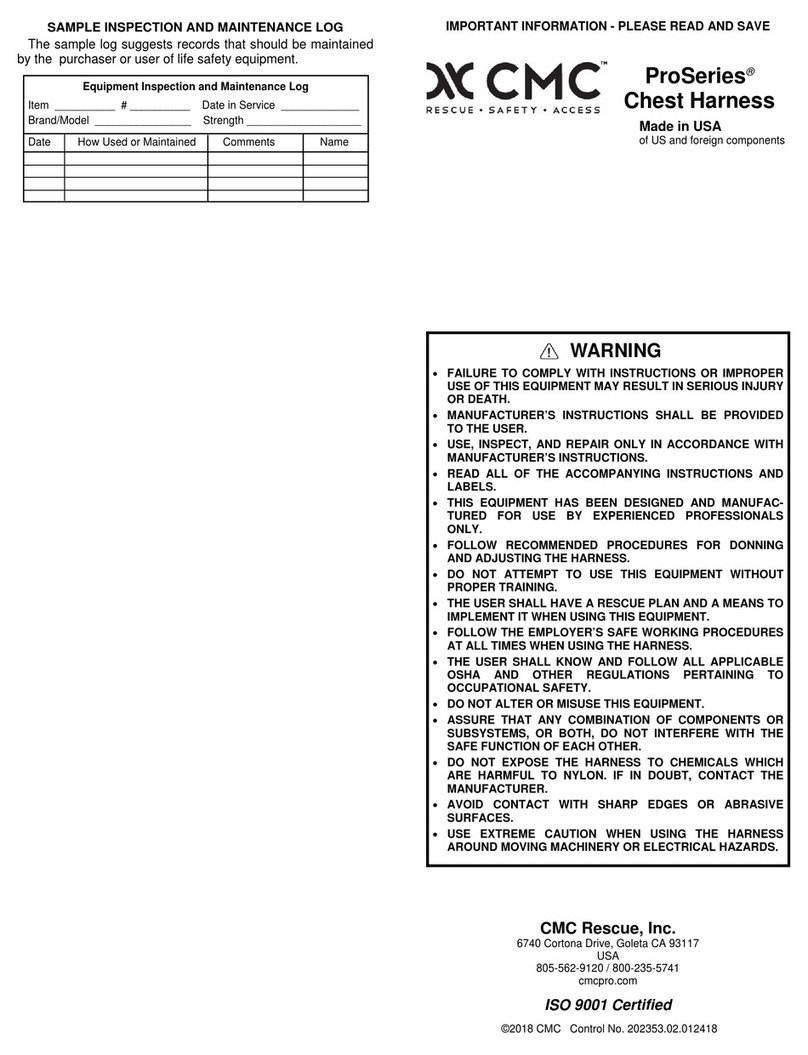

IMPORTANT INFORMATION - PLEASE READ AND SAVE

Made in USA

of US and foreign components

THIS DESCENT CONTROL DEVICE MEETS THE AUXILIARY EQUIPMENT

REQUIREMENTS OF NFPA 1983, STANDARD ON LIFE SAFETY ROPE AND

EQUIPMENT FOR EMERGENCY SERVICES, 2012 EDITION.

EMERGENCY SERVICES AUXILIARY EQUIPMENT

IN ACCORDANCE WITH NFPA 1983 – 2012.

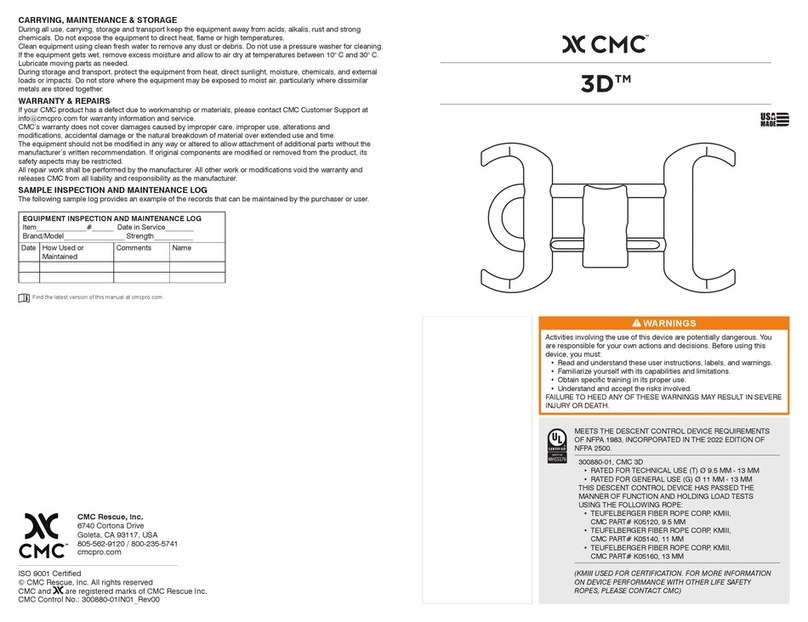

3D

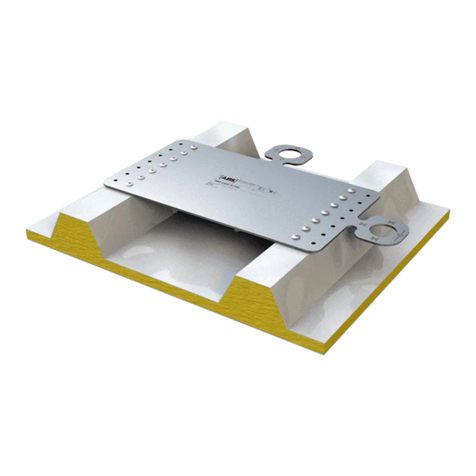

PRODUCT LABEL

300880 - 3D

CMC Rescue, Inc.

6740 Cortona Drive, Goleta CA 93117

USA

805-562-9120 / 800-235-5741

cmcrescue.com

ISO 9001 Certified

©2016 CMC Rescue, Inc. Control No. 300880.01.080116

Equipment Inspection and Maintenance Log

Item __________ # __________ Date in Service _____________

Brand/Model ________________ Strength ___________________

Date How Used or Maintained Comments Name

USER INFORMATION

User Information shall be provided to the user of the product. NFPA Standard 1983 recommends

separating the User Information from the equipment and retaining the information in a permanent

record. The standard also recommends making a copy of the User Information to keep with the

equipment and that the information should be referred to before and after each use.

Additional information regarding life safety equipment can be found in NFPA 1500, Standard on

Fire Department Occupational Safety and Health Programs, and NFPA 1983, Standard on Life

Safety Rope and Equipment for Emergency Services.

USE

The 3D Descender allows the user to control a wide range of loads by varying the path of the

rope through the device as well as increasing and decreasing the space between the bars to control

friction.

It is important that before commencing a lowering operation all bars and horns be engaged and

the descender be securely tied off. After loading the system, slowly untie the descender and begin

with the maximum friction obtained by having the rope running over at least two of the horns. See

opposite page for rigging diagrams.

When rigging the descender, always make sure that the center bar is securely engaged to

the frame and the locking button is fully extended to the end of the center bar. The center bar

should not disengage from the frame without depressing the locking button. To prevent

roll-out, only use locking carabiners.

INSPECTION

Inspect the equipment according to your department's policy for inspecting life safety equipment.

The equipment should be thoroughly inspected after each use by an inspector that meets your

department's training standard for inspection of life safety equipment. Record the date of the

inspection and the results in the equipment log or on a tag that attaches to the equipment. Each

user should be trained in equipment inspection and should inspect the equipment before each use.

Inspect the equipment for cracks, sharp edges, dents, corrosion, burrs or excessive wear. Minor

nicks or sharp spots may be smoothed with emery cloth. If any of the above is noted, or if the

equipment has been subjected to shock loads, fall loads, or abuse other than normal use, remove

the equipment from service and destroy it. If there is any doubt about the serviceability of the

equipment, remove the equipment from service and destroy it.

The service life of equipment used for rescue depends greatly on the type of use and the

environment of use. Because these factors vary greatly, a precise service life of the equipment

cannot be provided.

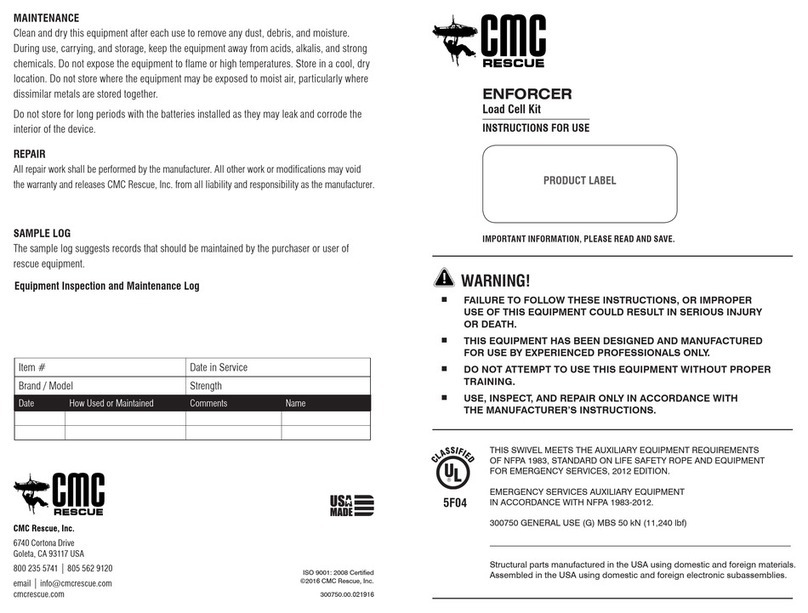

MAINTENANCE

Clean and dry this equipment after each use to remove any dust, debris, and moisture. During

use, carrying, and storage keep the equipment away from acids, alkalis, and strong chemicals. Do

not expose the equipment to flame or high temperatures. Store in a cool, dry location. Do not store

where the equipment may be exposed to moist air, particularly where dissimilar metals are stored

together.

REPAIR

All repair work shall be performed by the manufacturer. All other work or modifications will void

the warranty and releases CMC Rescue, Inc. from all liability and responsibility as the manufacturer.

SAMPLE LOG

The sample log suggests records that should be maintained by the purchaser or user of rescue

equipment.

THIS DESCENT CONTROL DEVICE HAS PASSED THE MINIMUM BREAKING

STRENGTH AND HOLDING LOAD TEST USING THE FOLLOWING ROPE:

TEUFELBERGER FIBER ROPE CORP, KMIII, CMC PART# K05120, 9.5mm.

TEUFELBERGER FIBER ROPE CORP, KMIII, CMC PART# K05160, 13mm.

(KMIII USED FOR CERTIFICATION. FOR INFORMATION ON PERFORMANCE WITH OTHER LIFE SAFETY

ROPES, PLEASE CONTACT CMC RESCUE)

WARNING

• SERIOUS INJURY OR DEATH MAY RESULT FROM THE IMPROPER USE OF THIS

EQUIPMENT.

• THIS EQUIPMENT HAS BEEN DESIGNED AND MANUFACTURED FOR USE BY

EXPERIENCED PROFESSIONALS ONLY.

• DO NOT ATTEMPT TO USE THIS EQUIPMENT WITHOUT PRIOR TRAINING.

• CMC RESCUE RECOMMENDS ALWAYS USING AN INDEPENDENT OR SELF-BELAY

WHEN WORKING ON ROPE.

• THOROUGHLY READ AND UNDERSTAND ALL LABELS AND INSTRUCTIONS BEFORE

USE.

• USE, INSPECT AND REPAIR ONLY IN ACCORDANCE WITH MANUFACTURER’S

INSTRUCTIONS.