WV4262B POWERED DAMPER WATER HEATER CONTROLS

769-2496—05

Gas Leak Test

1. Paint pipe connections upstream of the water

heater control with rich soap and water solution.

Bubbles indicate a gas leak.

2. If a leak is detected, tighten the pipe connections.

3. Stand clear of the burner while lighting to prevent

injury caused from hidden leaks that could cause

flashback in the appliance vestibule.

4. With the burner in operation, paint the pipe joints

(including adapters) and the control inlet and outlet

with rich soap and water solution.

5. If another leak is detected, tighten the adapter

screws, joints, and pipe connections.

6. Replace the part if a leak cannot be stopped.

Perform Gas Input and Burner

Ignition Check and Adjustment

Fire or Explosion Hazard

Can cause severe injury, death, or property damage.

Follow these warnings exactly:

1. Do not exceed input rating stamped on appliance

nameplate, or manufacturers recommended burner

orifice pressure for size orifice(s) used. Follow

instructions of appliance manufacturer.

2. IF CHECKING GAS INPUT BY CLOCKING GAS

METER: Make certain there is no gas flow through

the meter other than to the appliance being

checked. Other appliances must remain off with the

pilots extinguished (or that consumption must be

deducted from the meter reading). Convert flow rate

to Btuh as described in form 70-2602, Gas Controls

Handbook, and compare to Btuh input rating on

appliance nameplate.

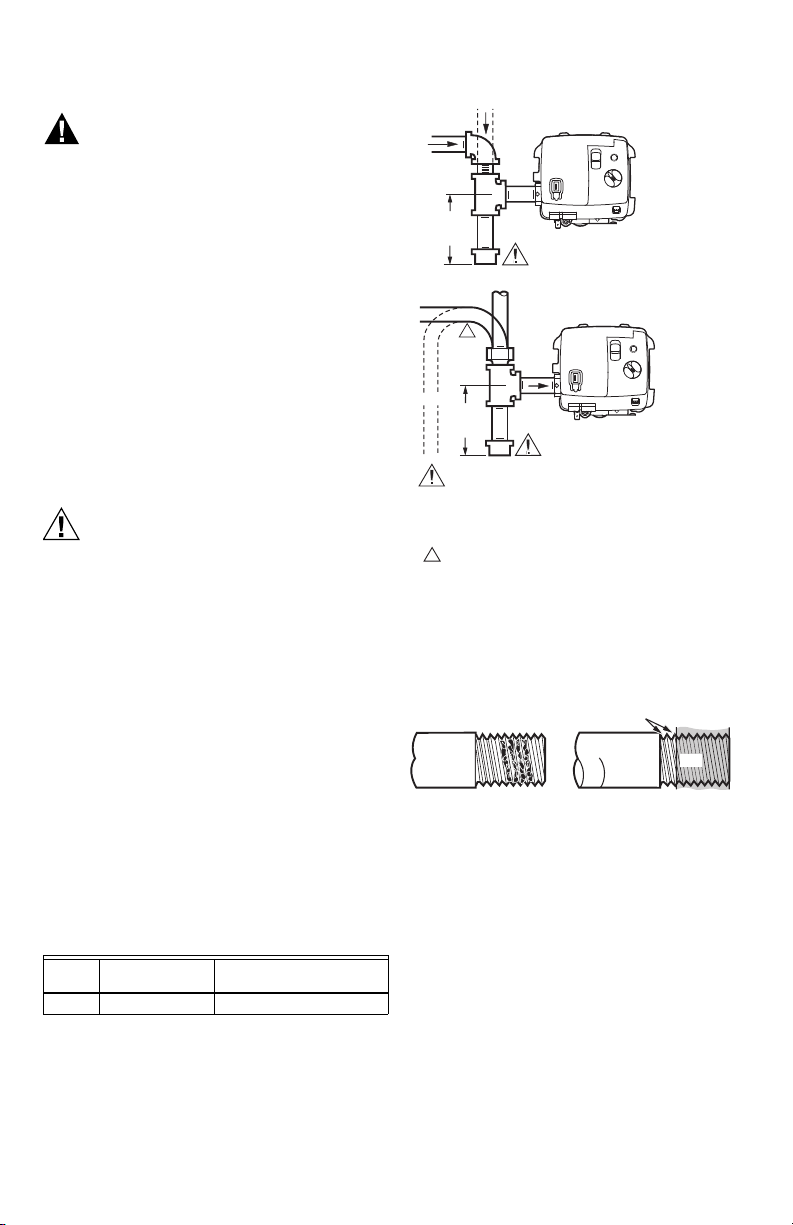

3. IF CHECKING GAS INPUT WITH MANOMETER:

Make sure the manual gas shutoff switch is in the

OFF position before removing outlet pressure tap

plug to connect manometer (pressure gauge). Also

move the manual gas shutoff switch to the OFF

position when removing the gauge and replacing the

plug. Repeat Gas Leak Test at plug with main burner

operating.

Refer to the OS label on the Control for the pressure

reading, which should match the manometer

reading.

Gas Input and Burner Ignition Check

and Adjustment

1. Check the full rate manifold pressure listed on the

appliance nameplate. Water heater control full rate

outlet pressure should match this rating.

2. With burner operating, check the water heater

control flow rate using the meter clocking method

or check pressure using a manometer connected

to the outlet pressure tap on the water heater

control.

a. Meter Clocking: Convert flow rate to Btuh as

described in form 70-2602, Gas Controls Hand-

book, and compare to Btuh input rating on

appliance nameplate.

b. Manometer: Refer to the OS label on the Control

for the pressure reading, which should match

the manometer reading.

Perform Flame Current Check

1. Turn the temperature control knob to call for heat.

2. Observe the pilot burner during the ignition

sequence and see if:

a. Ignition spark continues after the pilot is lit.

b. The pilot lights and the spark stops, but main

burner does not light

c. The pilot lights, the spark stops, and main

burner light, but the system locks out.

3. If so, ensure adequate flame current as follows:

a. Turn off water heater at circuit breaker or fuse

box.

b. Clean the flame rod with emery cloth.

c. Make sure electrical connections are clean and

tight.

d. Check for cracked ceramic Insulator, which can

cause short to ground, and replace igniter--

sensor if necessary.

e. Check the pilot flame. Make sure it is blue,

steady, and envelops 3/8 to 1/2 in. (10 to 13

mm) of the flame rod.

4. After completing step 3, if any conditions in step 2

above recur, then replace the Control.