HYBO - HYDRAULIC INTERFACE UNIT

EN1H-2615GE25 R1020 6

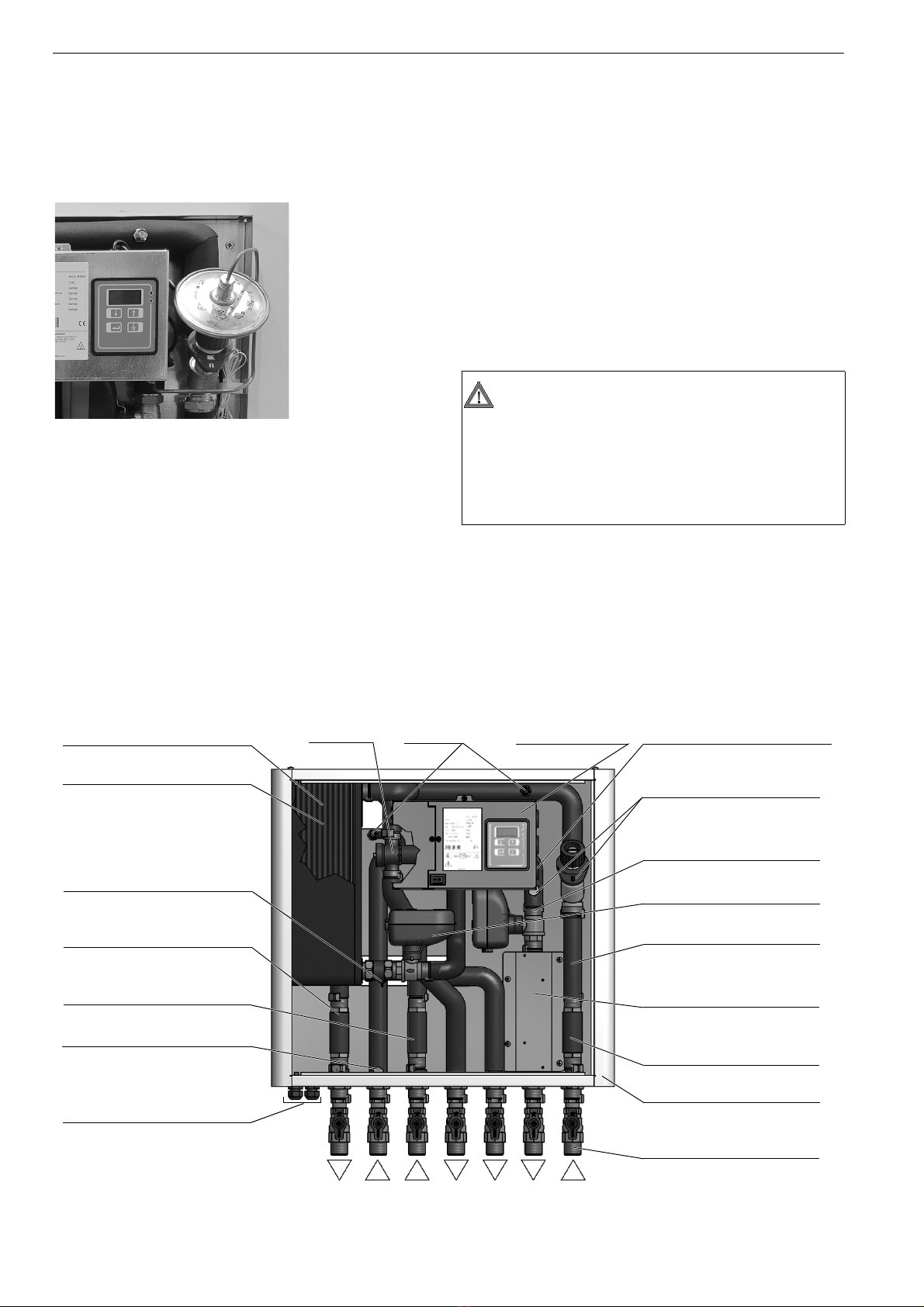

Programming for Technician

Access to programming menu. When digital display shows “OFF”, push

simultaneously “A” and “B” buttons. When display shows “P1” release

buttons. ”A and “B” buttons scroll main menu and increase or decrease value

in under menu. “ENTER” button goes into sub menu and save data itself.

(*) Anti-burns function intervenes when the sensor, positioned on hot sanitary

water delivery, feels a temperature superior to “set-point + P3 value”. In this

condition the modulating 2-way valve, positioned on heat exchanger primary,

is forced to complete closure and interrupts the erogation of thermal energy.

When temperature goes down to “set-point + P3 value”, the system automat-

ically starts normal production of sanitary hot water again.

(**) When warmed heat exchanger function is activated (P5 =0) the primary

circuit of the heat exchanger is constantly maintained in temperature (even

in absence of sanitary drawing) thanks to the passage of a small quantity of

hot water in primary circuit. This function can be activated when the unit is

away from distribution columns to reduce the DHW production delay time.

Deactivation of unit functions

During summer time, in order to deactivate heating function you have to set

the minimum temperature value on room thermostat or selecting “OFF”

mode, if present. Regarding sanitary function, excluding all takings is suffi-

cient and the module will automatically stop any energy inflow from central-

ized plant (if the warmed heat exchanger is deactivated). Besides, pressing

“ON/OFF” button on keypad is possible to deactivate hydraulic unit functions.

On display you find “OFF” and all functions are deactivated:both motorized

valves are on complete closing

Unit electrical disconnection

To disconnect the unit from electrical network follow these instructions:

1. Electrically disconnect ambient thermostat

2. Press “ON/OFF” button on keypad

3. Wait for about 30 sec. in order to give time to motorized valves to close.

4. Check that the motorized valves are in closed position by checking di-

rectional arrow position

5. Move the bi-polar switch on electrical box to OFF position

Control and regulations

DHW temperature

When the unit is activated and the display shows the temperature detected

by the probe, it is possible to adjust the set supply temperature of the hot

sanitary water. Use the buttons on the keypad:

Main menu Under menu Function

P1 X.X (sec) Where „X.X“ indicates time of sampling

temperature.

Regulation range 1.0 ³ 10.0 sec

(default 1.0 sec) for 24 plates heat exchanger

and 1.3 sec for 40 plates heat exchanger

P2 X (sec) Where „X“ indicates delay time ordered to

activation of sanitary hot water production by

flow meter signal (eco function)

Regulation range: 0 ³ 5 sec.

(default 0 sec)

P3 XX (°C) Where „XX“ indicates the Δtemperature to

be added to the setpoint to obtain the

maximum permitted temperature beyond

which the sanitary valve closes. Anti-burns

function*.

Regulation range 5 ³ 50°C

(default 5°C)

P4 XX (sec) Where „XX“ indicates delay time ordered to

anti burns function intervention.

Regulation range 0 30 sec

(default 0 sec)

P5 X Where „X“ is a Boolean variable that can be:

0 = warmed heat exchanger function acti-

vated **

1 = warmed heat exchanger function deacti-

vated

(default 1)

CAUTION

The anti-burns function helps to avoid supply of hot sanitary water

with dangerous temperatures. Installing devices for thermal safety for

sanitary uses to be placed below the unit is advised.

If the hot sanitary water temperature sensor is damaged or not

connected the display shows the allarm “ALt”. The modulating valve

of the plated exchanger primary circuit is forced to closing; the

flashing "AL t" is displayed. When the damage is restored the unit

start again with its normal functioning.

WARNING

Electrical power coming from ambient thermostat is NOT inter-

rupted by bi-polar switch. In order to complete disconnect the

hydraulic unit form electrical power interrupt ambient thermo-

stat power.

CAUTION

A disconnection from electric network made without operating as

described above does not grant the complete hydraulic isolation of

the module from the whole plant. As a consequence the module could

still take and regulate heat even though not requested.

Press the “A” button to decrease the temperature

value. Press the “B” button to increase the temperature

value. The display will show a value ranging from 0 to

10. 0 corresponds to approximately 40°C, 10 corre-

sponds to approximately 60°C. Then, press “ENTER”

to accept the value.