PART I GENERAL DESCRIPTION ON AIR CLEANING

1-1

1. IN DOOR AIR QUALITY

If you could see the air you breathe under a microscope, you might be in for a surprise. The air quality is much more

terrible than you may think. In fact, floating in indoor air is a "soup" of particles too small to be seen by your naked eye.

But it is large enough to cause problems. Visible dust makes up only 1% of all the particles in the air. The vast majority

of particles are microscopic.

How long the particles float in the air depends on their size. Relatively "heavy" dust particles (more than 5 microns)

tend to settle out of the air in 20 minutes or less. They form the dust that's easily wiped away on tables and other

surfaces. Middleweight particles (from 1 to 5 microns) may remain airborne for hours before falling out of the air.

Lightweight particles (less than 1 micron) can remain suspended permanently in the air. And particles sized less than 1

micron can gain the easiest entry to your body and place the biggest burden on its defense system.

No matter the type or size of the building - single family home, office, school, store, hotel, restaurant, hospital, or other

places - creating and maintaining good indoor air quality (IAQ) requires three key strategies: source control,

ventilation and air cleaning. Indoor air is an intriguing, complex environment that contains a myriad of visible and

invisible contaminants. These contaminants generally fall in one of two categories: particulates or gases, vapors and

odors.

Particulates

Particulates are particles that are small enough to suspend in the air. Suspended inorganic particles, such as dust,

pollen, fibers or smoke to name a few examples, are often referred to as aerosols. Suspended organic compounds

and small living organisms, such as bacteria and viruses; mold spores and pieces of a mold colony; dust mites feces

and body fragments; cockroach body parts; and dander from cats, dogs and other mammals, are called bio-aerosols.

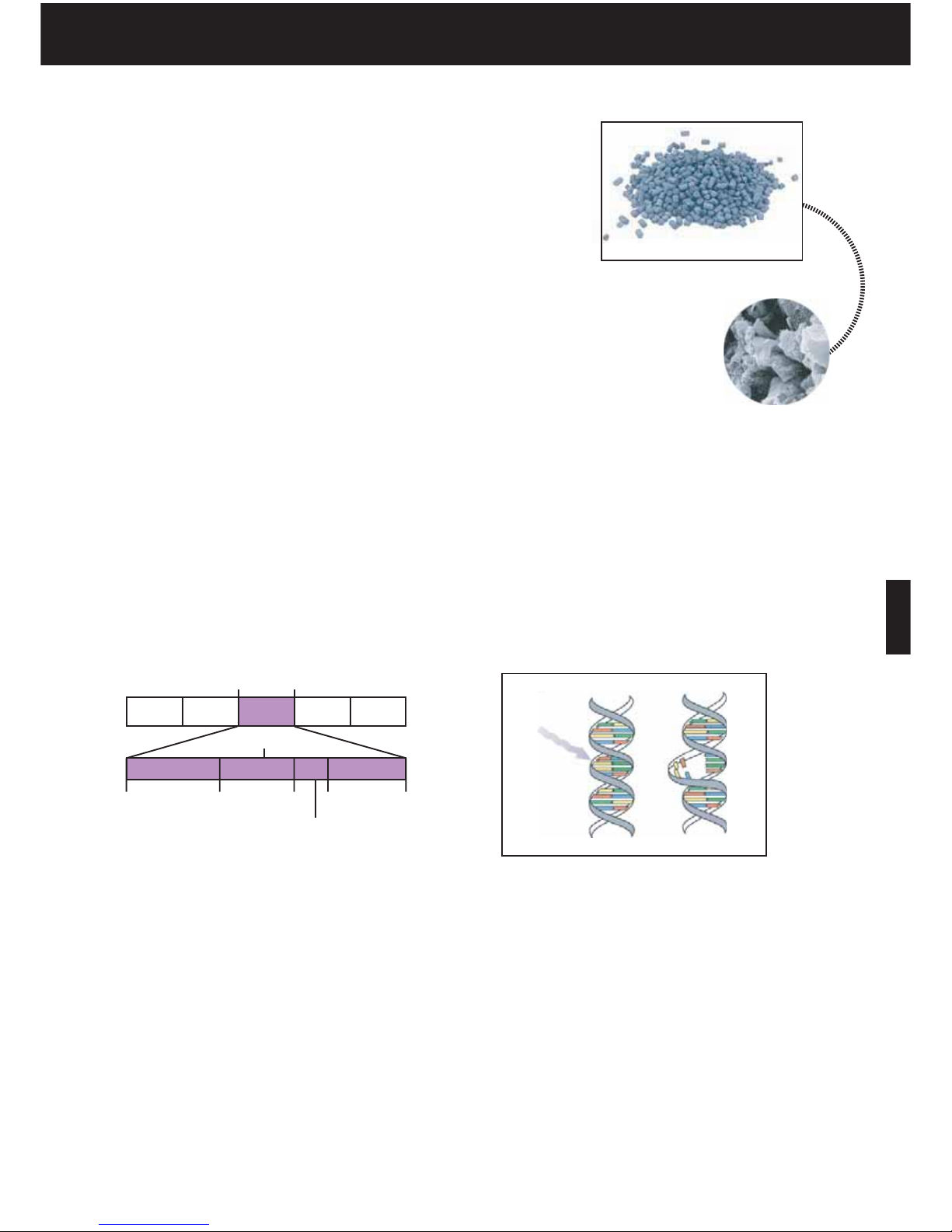

Particle size is measured in terms of its aerodynamic properties and is expressed as microns in diameter. Particles

can range in size from very small, which can remain in the air for a long time, up to relatively large, which quickly settle

out of calm air. Table 1 lists common indoor contaminants and their particle sizes.

Inhaling particulates can cause eye, nose and throat irritation and increase the risk for respiratory infections. Health

care professionals are especially concerned about the long-term effects of inhaling fine particles (less than 2.5

microns), because they can travel deep into the lungs where they can remain embedded for years or be absorbed into

the bloodstream. Asbestos and various substances in environmental tobacco smoke (ETS) are well-known examples

and some are recognized carcinogens. Exposure to high levels of fine particles also can play a role in developing

respiratory diseases such as asthma, bronchitis, pneumonia and emphysema. Larger particles (greater than 10

microns) do not cause as much concern, because they get caught in the nose and throat and are cleared from the

respiratory tract by coughing or swallowing.

Gases, Vapors and Odors

The types of gases or vapors most often found in indoor environments include combustion byproducts, such as

carbon monoxide, nitrogen oxides, sulfur dioxide, soot particles and polycyclic aromatic hydrocarbons (PAHs); pet,

human and cooking odors; ETS; volatile organic compounds (VOCs); microbial VOCs; and mycotoxins. Many of these

substances also produce odors, some of which are pleasant while others can be distracting and irritating. Moisture

also is a vapor that must be monitored as too much moisture can support indoor mold growth.

Volatile organic compounds are prevalent in all indoor environments, with as many as 100 to 1,000 different VOCs in

the air where people can easily inhale them. Exposure to VOCs in offices and other business establishments can

cause building occupants to feel uncomfortable, distracted or sick to the point that it interferes with their ability to do

their work or reduces their motivation to work. Reducing the level of VOCs also is very important in homes and

schools, because children breathe in more air with respect to their body mass than adults and thus have greater

exposure to indoor air pollutants. Some types of mold also emit VOCs, known as microbial VOCs or MVOCs, which

are responsible for the characteristic musty, earthy odors associated with mold. People who are sensitive to MVOCs

may experience eye, nose and throat irritation.

Table 1. Particle Sizes of Common Indoor Contaminants

Particle

Skin flakes

Visible dust, lint

Dust mite

Mite allergen

Mold, pollen spores

Cat dander

Bacteria

Viruses

Amoeba

Particle

Asbetos

Re-suspended dust

Environmental tobacco smoke

Diesel soot

Outdoor fine particles (sulfates, metals)

Fresh combustion particles

Metal fumes

Ozone

Mineral fibers

Size (micron)

1-40

>25

50

5-10

2-200

1-3

0.05-0.7

<0.01-0.05

8-20

Size (micron)

0.25-1

5-25

0.1-0.8

0.01-1

0.1-2.5

<0.1

<0.1

<0.1

3-10

ENGLISH