6

Warnings

1. This respirator, when properly tted and used, signicantly reduces, but does not completely

eliminate, the breathing of contaminants by the respirator wearer. You may obtain better respiratory

protection from other types of respiratory protection equipment such as a valve operated pressure-

demand airline respirator or a pressure-demand self-contained breathing apparatus respirator.

2. Before using this respirator, be sure your employer has determined that airborne contaminant

concentrations do not exceed those allowed by applicable OSHA, EPA, NIOSH or ACGIH regulations

and recommendations for continuous-ow supplied-air respirators. Federal law requires that your

employer measure and monitor airborne contaminant levels in the work area.

3. Improper respirator use may damage your health and/or cause your death. Improper use may also

cause certain life threatening delayed lung diseases such as silicosis, pneumoconiosis or asbestosis.

4. DO NOT wear this respirator if any of the following conditions exist.

• Atmosphere is immediately dangerous to your life or health.

• You CANNOT escape without the aid of the respirator.

• Atmosphere contains less than 19.5% oxygen.

• Work area is poorly ventilated.

• Unknown contaminants are present.

• Contaminants are in excess of regulations or recommendations (as described in item 2 above).

5. DO NOT wear this respirator until you have passed a complete physical exam (perhaps including

a lung X-ray) conducted by qualied medical personnel, and have been trained in the respirator’s

use, maintenance and limitations by a qualied individual (appointed by your employer) who has

extensive knowledge of the Respirex supplied-air respirator.

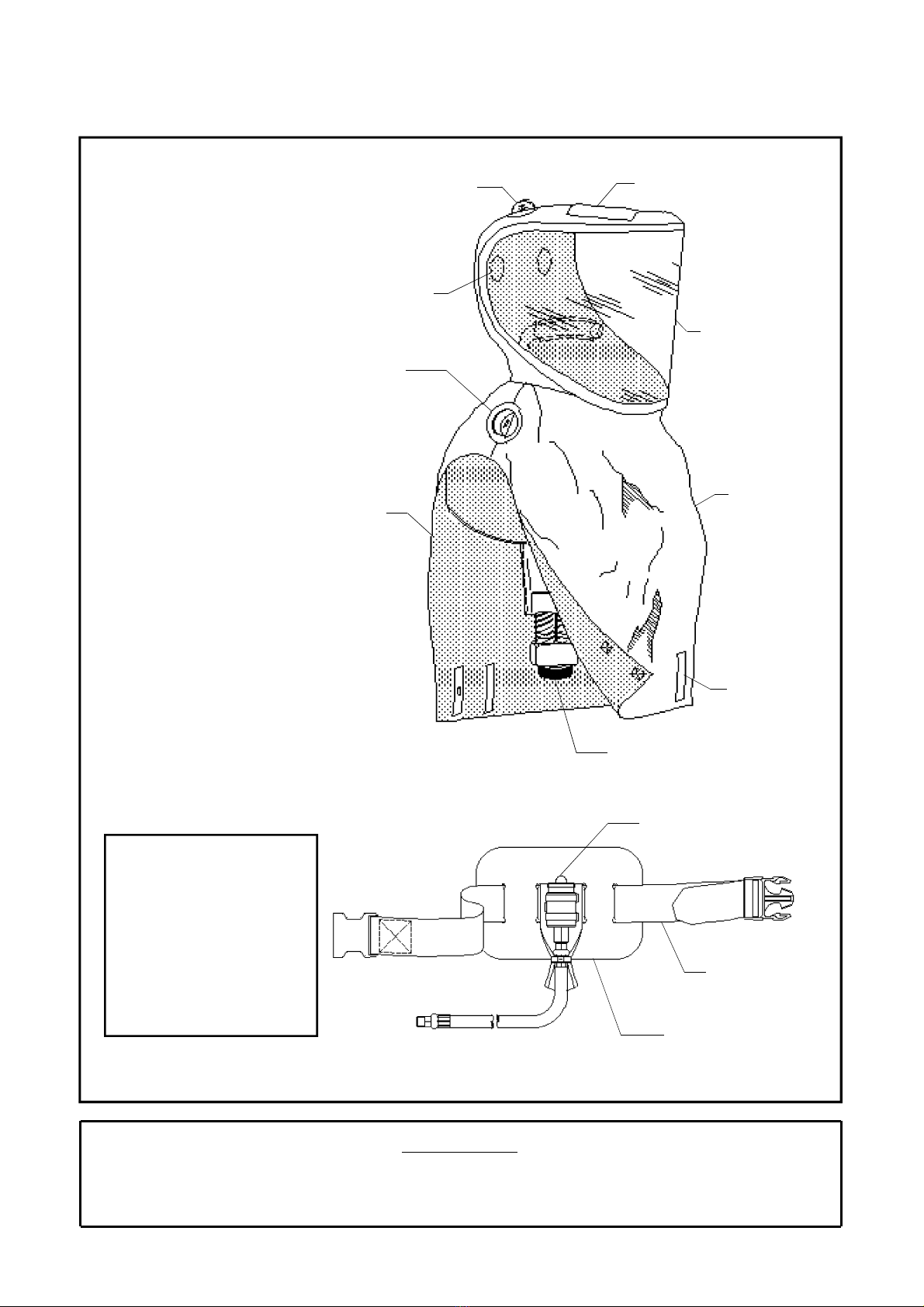

6. DO NOT modify or alter this respirator in any manner. Use only NIOSH approved Respirex components

and replacement parts manufactured by Respirex for use with this respirator.

Failure to use NIOSH approved Respirex components and replacement parts such as visors, hoses and

ow control devices, voids NIOSH approval of the entire respirator, invalidates all Respirex warranties,

and may cause death, lung disease or exposure to other hazardous or life threatening conditions.

7. Inspect all components of this respirator system daily for signs of wear, tear or damage that might

reduce the degree of protection originally provided.

Immediately replace worn or damaged components with NIOSH approved Respirex Simplair

components or remove respirator from service (See INSPECTION AND STORAGE section on pages

14 and 19 for proper maintenance of the supplied-air respirator).

8. Be certain your employer has determined that the breathing air source provides at least Grade D or

better breathable air as specied by C.G.A. commodity specication G-7-1. This respirator must be

supplied with clean breathable air at all times.

9. DO NOT connect the respirator’s air supply hose to nitrogen, toxic gases, inert gases or other

unbreathable, non-Grade D air sources. Check the air source before using the respirator. Failure to

connect to the proper air source may result in death or serious injury.

10. DO NOT use this respirator in poorly ventilated areas or conned spaces such as tanks, small rooms,

tunnels or vessels unless the conned space is well ventilated and the contaminant concentrations

are below the upper limit recommended for this respirator. In addition, follow all procedures for

conned space entry, operation and exit as dened in applicable regulations and standards, including

29 CFR 1910.146.