ASSEMBLY INSTRUCTIONS

KODA 12 & KODA 16

TOOLS

1

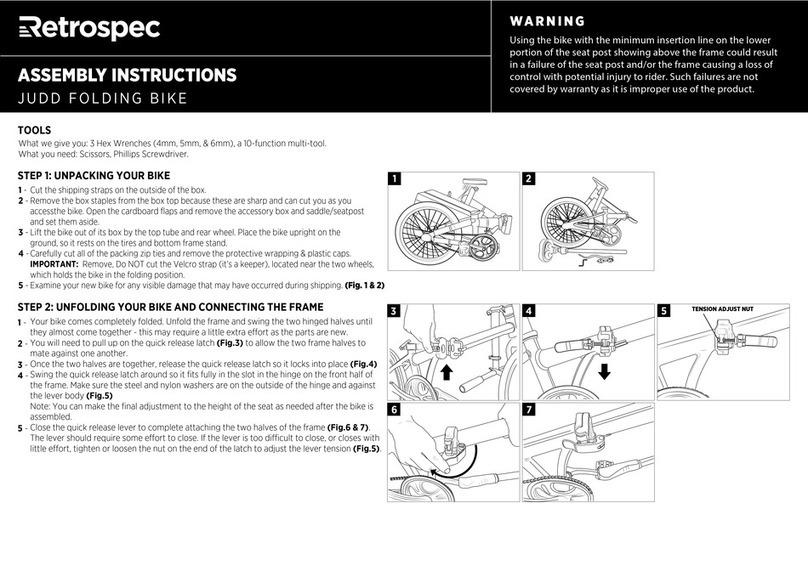

STEP 1: UNPACKING YOUR BIKE

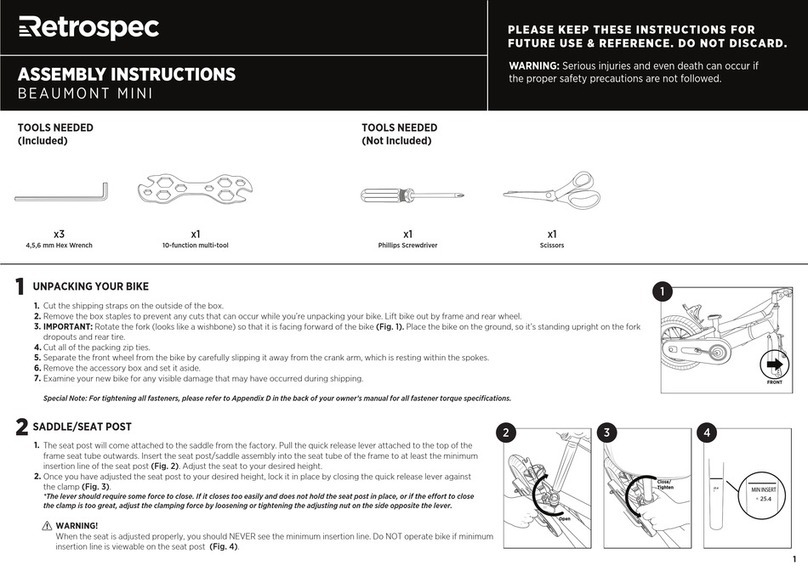

STEP 2: SADDLE/SEATPOST

WARNING

Using the bike with the minimum insertion line on the lower

portion of the seat post showing above the frame could result

in a failure of the seat post and/or the frame causing a loss of

control with potential i is improper use of the product.

What we give you: 3 Hex Wrenches (4mm, 5mm, & 6mm), a 10-function multi-tool.

What you need: Scissors, Phillips Screwdriver.

Cut the shipping straps on the outside of the box.

Remove the box staples as these are sharp and can cut you as you access the bike. Lift bike out by frame and rear wheel.

Rotate the fork so that it is facing forward of the bike (Fig.1). Place the bike on the ground, so it’s standing upright on the fork dropouts and rear tire.

Cut all of the packing zip ties.

Separate the front wheel from the bike by carefully slipping it away from the crank arm, which is resting within the spokes.

Remove the accessory box and set it aside.

Examine your new bike for any visible damage that may have occurred during shipping.

Special Note: For tightening all fasteners, please refer to Appendix D in the back of your owner’s manual for all fastener torque specifications.

1-

2-

3-

4-

5-

6-

7-

1-

2-

The seat post will come attached to the saddle from the factory. Pull the quick release lever attached to the top of the frame seat

tube outwards. Insert the seat post/saddle assembly into the seat tube of the frame to at least the minimum insertion line of the

seat post (Fig.2). Adjust the seat to your desired height.

Once you have adjusted the seat post to your desired height, lock it in place by closing the quick release lever against the clamp

(Fig.3).

The lever should require some force to close. If it closes too easily and does not hold the seat post in place, or if the eort to close

the clamp is too great, adjust the clamping force by loosening or tightening the adjusting nut on the side opposite the lever.

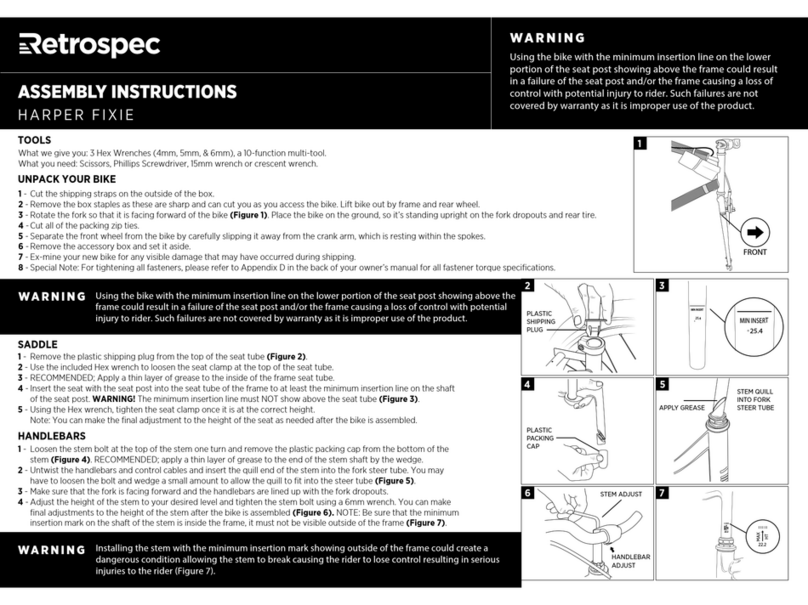

STEP 3: HANDLEBAR

1-

2-

3-

4-

5-

The stem is secured into fork steer tube from the factory.

Using a hex wrench, remove the 4 bolts/washers of the handlebar clamp on the underside of the stem (Fig.5).

Untwist the handlebar and brake cable and face the handlebar forward (reflector facing forward).

Make sure that the fork is facing forward(Fig.1).

Place the handlebar in the stem and the stem top clamp over the handlebar. Center the handlebar in the stem. Install the 4 stem

bolts. Tighten each bolt a little at a time to ensure even pressure on all four corners using a cross pattern (Fig.6).

WARNING!

Never adjust the seat height so that the minimum insertion line at the lower end of the seat post is showing outside of the frame

(Fig.4).

2

5 6

3 4

Front

25.4

MIN INSERT

25.4

7

stem centerbolt

(adjusts direction)

Handlebar

Clamp

Open

Close/

Tighten

loosen

tighten

securely

stem

FRONT