ASSEMBLY INSTRUCTIONS

AMOK URBAN GRAVEL BIKE

TOOLS

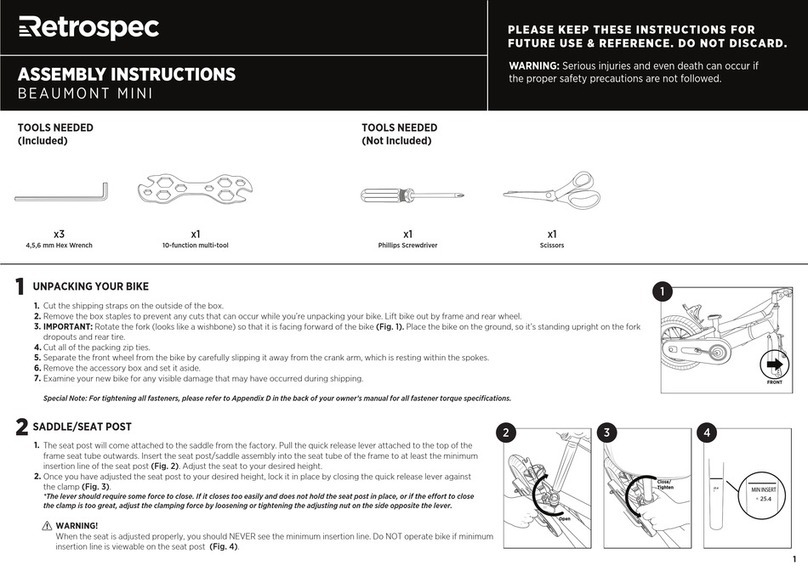

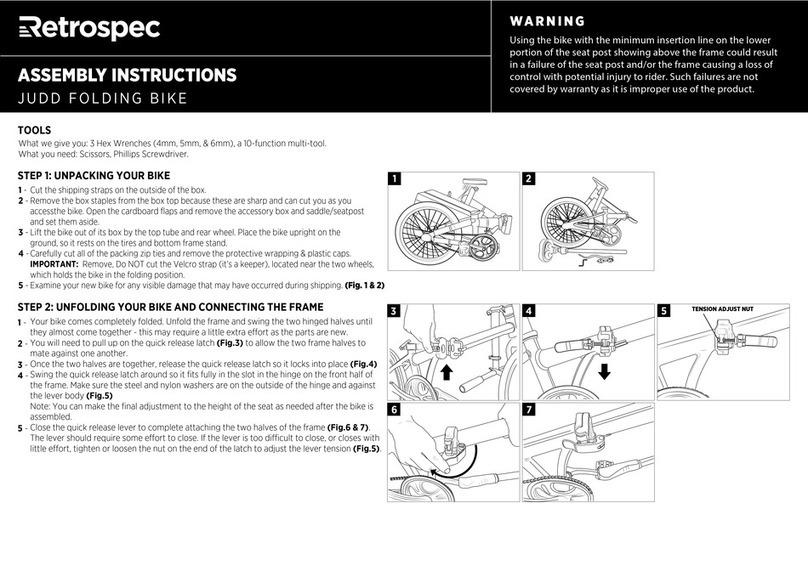

STEP 1: UNPACKING YOUR BIKE

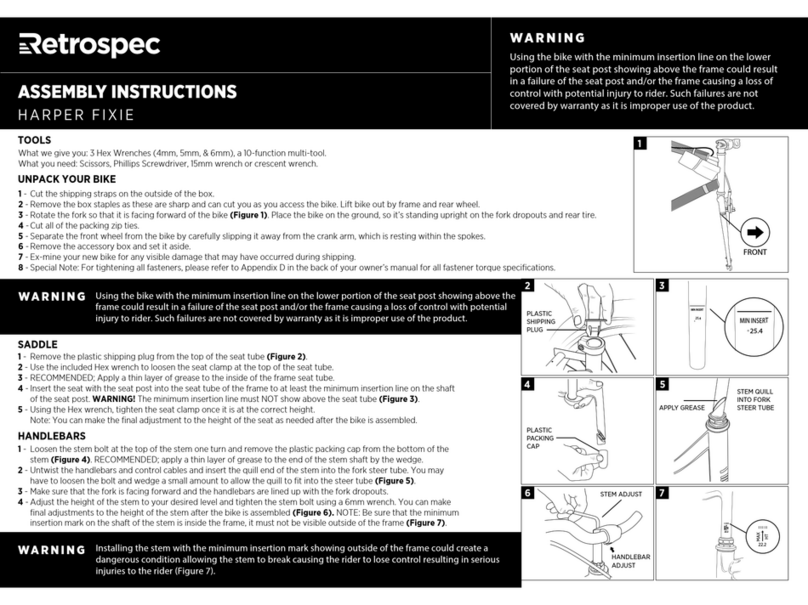

STEP 2: INSTALLING SADDLE

WARNING

Using the bike with the minimum insertion line on the lower

portion of the seat post showing above the frame could result

in a failure of the seat post and/or the frame causing a loss of

control with potential injury to rider. Such failures are not

covered by warranty as it is improper use of the product.

What we give you: 2 Hex Wrenches (5mm, & 6mm), a 10-function multi-tool.

What you need: Scissors, Phillips Screwdriver, 15mm wrench or crescent wrench.

Make sure bike is upright, cut the shipping straps on the outside of the box.

Remove the box staples as these are sharp and can cut you as you access the bike.

Lift bike out by frame and rear wheel. Inspect your new bike.

Rotate the fork so that it is facing forward of the bike (Figure 1). Place the bike on the ground,

so it’s standing upright on the fork dropouts and rear tire.

Use scissors to cut all of the packing zip ties.

Separate the front wheel from the bike by carefully slipping it away from the crank arm,

which is resting within the spokes – set aside for now.

Remove the accessory box - set aside for now.

Examine your new bike for any visible damage that may have occurred during shipping and

make sure you have all of its bits and pieces.

Special Note: For tightening all fasteners, please refer to Appendix D in the back of your owner’s

manual for all fastener torque specifications.

1-

2-

3-

4-

5-

6-

7-

8-

1-

2-

3-

4-

Remove the plastic shipping plug from the top of the seat tube (Figure 2).

Use the included hex wrench to loosen the seat clamp at the top of the seat tube.

Insert the seat with the seat post into the seat tube of the frame to at least the minimum

insertion line on the shaft of the seat post and aligning saddle with frame.

WARNING! The minimum insertion line must NOT show above the seat tube (Figure 3)

Using the hex wrench, tighten the seat clamp once it is at the correct height.

Note: You can make the final adjustment to the height of the seat as needed after the bike is

assembled.

WARNING! Using the bike with the minimum insertion line on the lower portion of the seat

post showing above the frame could result in a failure of the seat post and/or the frame caus-

ing a loss of control with potential injury to rider. Such failures are not covered by warranty as

it is improper use of the product (Figure 3).

1 2

3

.