t.

www.infinitycycleworks.com

copyright 2018 - Infinity Cycle Works Ltd.

DISC BRAKES

Your bike is fied with a front disc brake, and the components should already be aached.

However, please check all connecons before aempng to ride the bicycle. Secure ghtly

the 6 bolts that hold the disc to the front wheel hub and the 2 bolts that hold the brake

mechanism to the fork. Double check that the front hub is inserted into the fork drop outs

correctly and that the quick release is closed and secure.

DISC GETS HOT! Severe injury could result from contact with the hot disc! Mind

your legs, as well as your hands.

If your bike is equipped with a front disc brake, be careful not to damage the

disc, caliper or brake pads when re-inserng the disc into the caliper. Never

acvate a disc brake’s control lever unless the disc is correctly inserted in the

caliper.

These brakes require breaking in! Ride and use the brakes gently for a few miles

before using the brakes in downhill condions, for sudden stops, or any other

serious braking. Please be aware that your brake system will change in

performance throughout the wear-in process. The disc brake should be cleaned

before the first ride using rubbing alcohol. NEVER use oil or similar products to

clean your disc brake system.

FRONT WHEEL

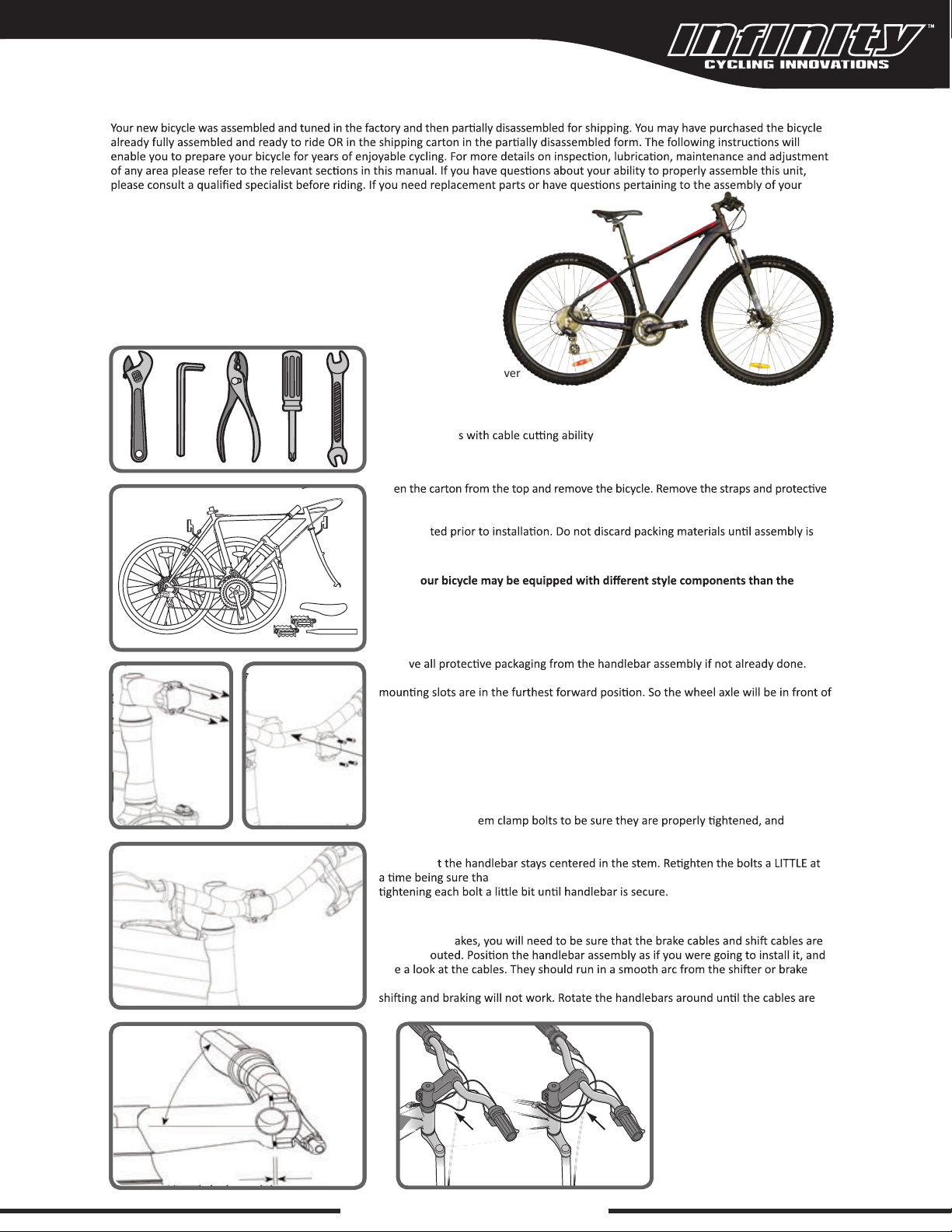

1. Locate the quick release skewer from the small parts carton of your bicycle.

2. Unscrew the lock nut from the quick release skewer, remove outer spring and slide the

skewer through the front wheel axle.

3. Install spring and then start to thread the lock nut back onto the skewer, but do not

ghten too far.

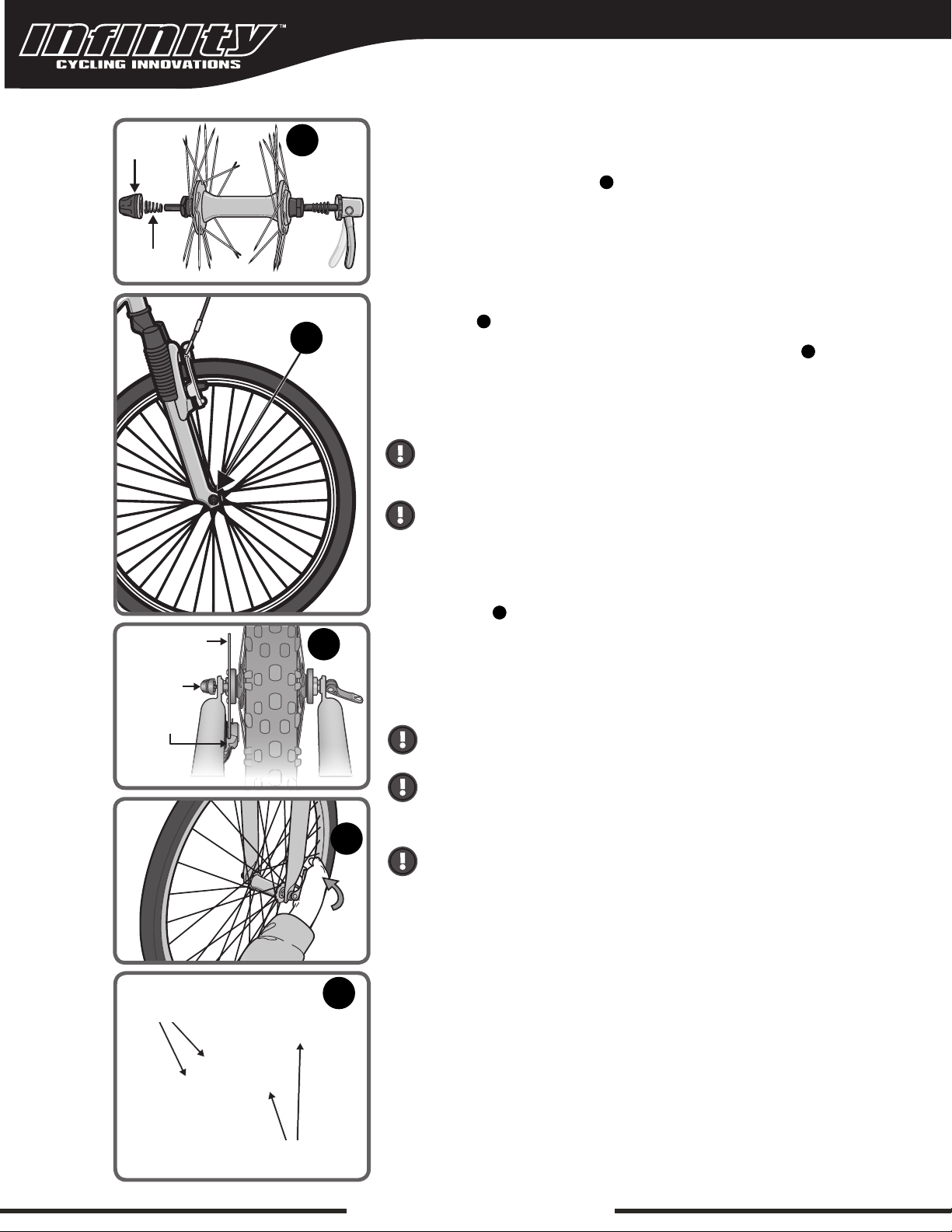

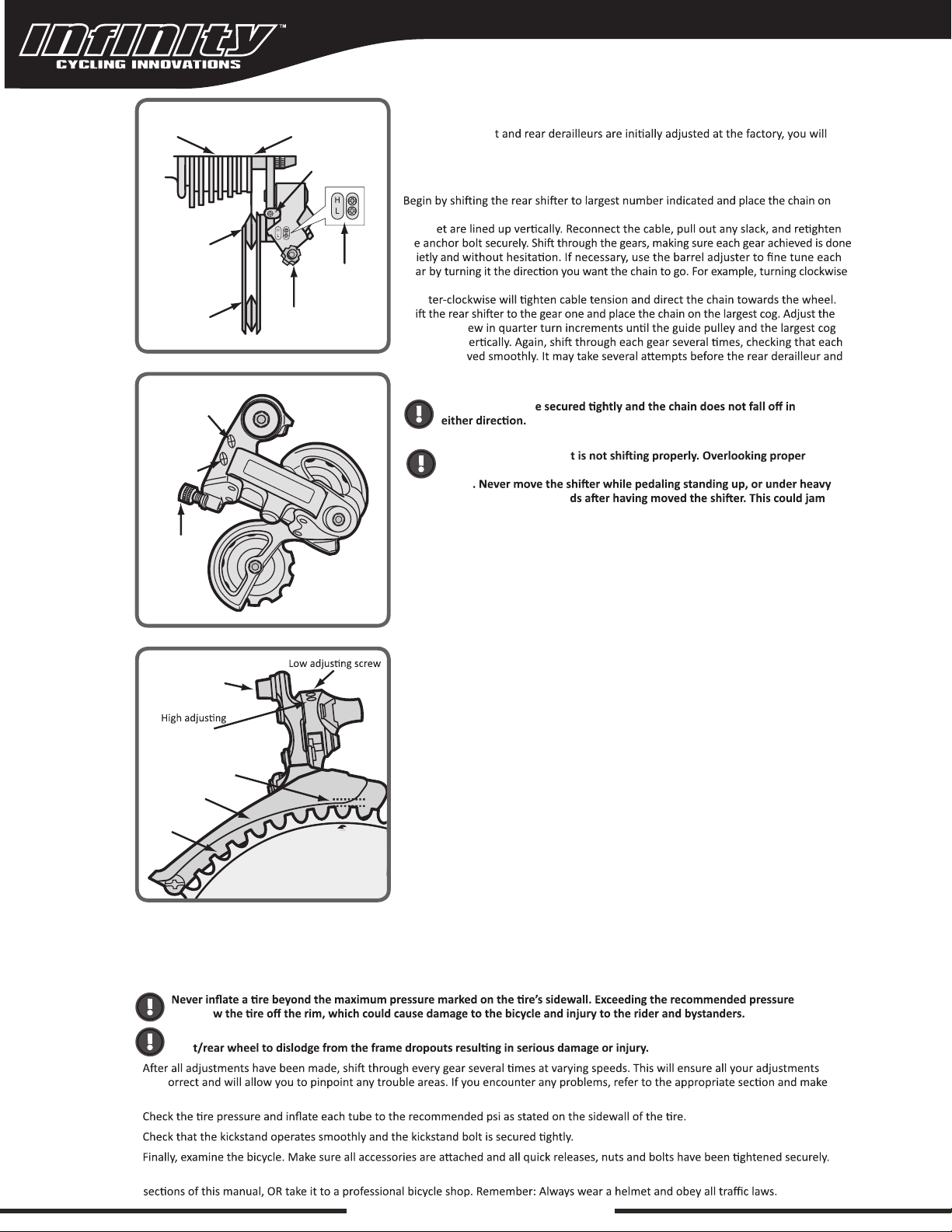

4. Slide the wheel into the fork wheel slots and be sure that the wheel is centered. Your

front wheel has a disc brake, insert the disc rotor into the slot on the caliper body as

you insert the wheel axle into the fork drop out.

5. The handle on the quick release has an “open” and a “closed” posion. Move the

handle so it is in the “open” posion. With one hand on the handle and one hand on

the lock nut, start to hand ghten the lock nut unl you start to feel some resistance

with the fork.

6. Try to close the handle. If it closes easily, open it up, and ghten the lock nut further. If

it is too difficult to close, open the handle, and loosen the lock nut try again.

7. The quick release handle should be difficult to push closed with your palm, but should

be possible. Pracce opening and closing the handle unl you feel comfortable. DO NOT

aempt to ghten the wheel by turning the handle to ghten; the handle is for securing

the wheel, use the lock nut for adjusng tension.

All quick release levers should be inspected before every ride to be sure they are

fully closed and secure. Failure to properly close the quick release lever can cause

loss of control of the bicycle resulng in injury or death.

Make sure the wheel is properly seated and the quick release is properly closed.

Lock

Nut

Quick release

skewer

Outer

Spring

1

1

3

4

5

2

3

4

Lock Nut

Open

Disc rotor

Disc brake

caliper body

Close

Disc Bolts

Brake Mechanism

5