11/6/2012 3 Retsch GmbH 0002

Notes on these operating instructions ..................................... 2

Safety...................................................................................... 4

Safety instructions ............................................................................4

Warning signs...................................................................................5

Repairs ............................................................................................5

Confirmation ....................................................................................8

Technical data ......................................................................... 9

Use according to the intended purpose ................................................9

Emissions.........................................................................................9

Protective system: IP53 ....................................................................9

Rated power: 230 Watt.....................................................................9

Machine dimensions ..........................................................................9

Required floor space ..........................................................................9

Transport and installation ..................................................... 10

Packing.......................................................................................... 10

Transport ....................................................................................... 10

Intermediate storage ....................................................................... 10

Conditions for the place of installation ............................................... 11

Installation..................................................................................... 11

Electrical connection ........................................................................ 11

Operation .............................................................................. 12

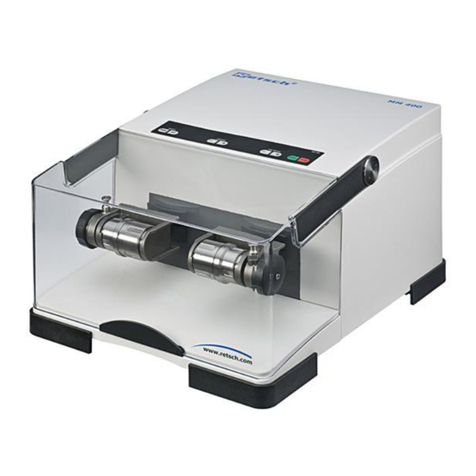

Operating elements and operation..................................................... 12

Operating elements and their function ............................................... 13

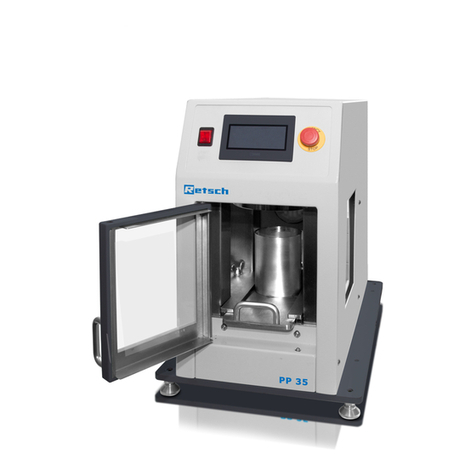

View of milling chamber................................................................... 15

Installing / changing the milling fittings ............................................. 16

Installing or changing the mortar ...................................................... 16

Installing or changing the pestle ....................................................... 17

Adjusting the pestle ........................................................................ 18

Adjusting the pestle pressure ........................................................... 18

Adjusting the Scraper to the Mortar................................................... 19

Adjusting the contact pressure.......................................................... 20

Checking the scraper setting ............................................................ 21

Control milling operation.................................................................. 21

Adjusting the milling time ................................................................ 21

Stopping the milling process............................................................. 23

Replacing the machine fuses............................................................. 23

Working instructions ............................................................. 24

General.......................................................................................... 24

Materials........................................................................................ 24

Crushing, mixing and milling of samples with grain size < 3mm ............ 25

Crushing, mixing and milling materials of grain size > 3 mm ................ 26

Security advice for handling liquid nitrogen ........................................ 27

Safety functions and fault displays ........................................ 28

Safety functions .............................................................................. 28

General ................................................................................. 29

Cleaning ........................................................................................ 30

Maintenance ................................................................................... 30

Accessories RM200.......................................................................... 30

Wear ............................................................................................. 31

Readjusting the lock pre-tensioning................................................... 31

Wearing parts................................................................................. 31

Checks........................................................................................... 31

Copyright ....................................................................................... 31

Alterations ..................................................................................... 31

Summary of safety regulations for the RM200..................................... 32