3

1Notes on the Operating Manual ............................................................................................................ 5

1.1 Explanations of the safety warnings.................................................................................................. 6

1.2 General safety instructions................................................................................................................ 7

1.3 Repairs............................................................................................................................................... 8

2Confirmation ........................................................................................................................................... 9

3Transport, scope of delivery, installation .......................................................................................... 10

3.1 Packaging........................................................................................................................................ 10

3.2 Transport.......................................................................................................................................... 10

3.3 Temperature fluctuations and condensed water ............................................................................. 10

3.4 Conditions for the place of installation............................................................................................. 10

3.5 Electrical connection........................................................................................................................ 11

3.6 Type plate description...................................................................................................................... 12

3.7 Removing Transport Safeguards..................................................................................................... 12

3.8 Frame assembly.............................................................................................................................. 14

3.9 Mounting the Feed Hopper.............................................................................................................. 18

3.9.1 Removing the Transport Safeguard ............................................................................................ 18

3.9.2 Mounting the Feed Hopper.......................................................................................................... 18

3.10 Installation of the machine............................................................................................................... 19

4Technical data ....................................................................................................................................... 21

4.1 Use of the machine for the intended purpose.................................................................................. 21

4.2 Emissions......................................................................................................................................... 21

4.3 Degree of protection ........................................................................................................................ 22

4.4 Motor rotation speed........................................................................................................................ 22

4.5 Receptacle volume .......................................................................................................................... 22

4.6 Rated power .................................................................................................................................... 22

4.7 Dimensions and weight.................................................................................................................... 22

4.8 Required floor space........................................................................................................................ 23

5Operating the machine ........................................................................................................................ 23

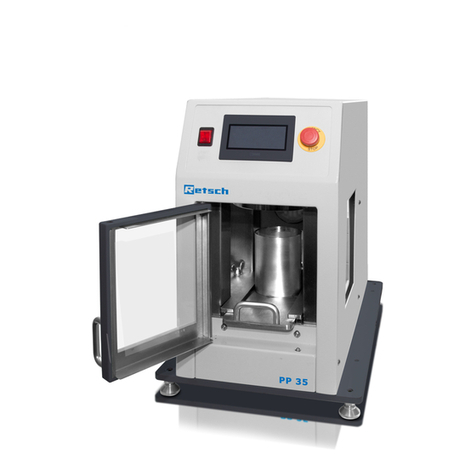

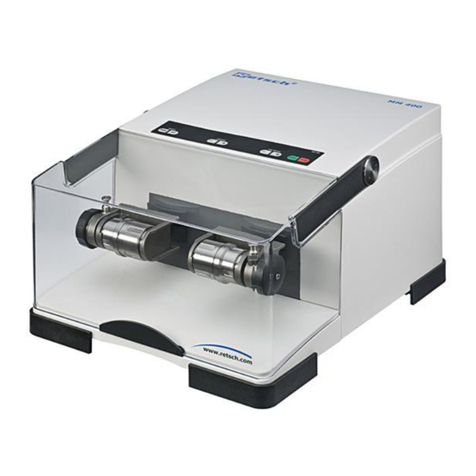

5.1 Views of the Instrument................................................................................................................... 23

5.2 Overview table of the parts of the device ........................................................................................ 26

5.3 Opening and closing of the grinding chamber................................................................................. 27

5.4 Mounting the bottom sieve............................................................................................................... 27

5.5 Replacing the rotor .......................................................................................................................... 27

5.5.1 Removing the Rotor..................................................................................................................... 28

5.5.2 Inserting the Rotor ....................................................................................................................... 28

5.6 Inserting the filter unit and collecting receptacle.............................................................................. 29

5.7 Switching On and Off....................................................................................................................... 29

5.8 Starting the grinding process........................................................................................................... 30