ALLRIGHTSARERESERVEDACCORDINGTOTHE

INTERNATIONALCOPYRIGHTCONVENTIONS,

Thereproductionof anypartof thismanual, inanyform,isforbiddenwithout

thepriorwrittenauthorizationofRasor®ElettromeccanicaS.r.l.

Thecontentof thisguidecanbemodifiedwithoutpriornotice.Greatcarehas

beentakenincollectingandcheckingthedocumentationcontainedinthis

manualto makeitascompleteandcomprehensibleaspossible.

Nothingcontainedinthismanualcanbeconsideredasawarranty,either

expressedorimplied-including,not inarestrictiveway,thesuitabilitywarranty

foranyspecialpurpose.Nothingcontainedinthismanualcanbeinterpretedasa

modificationorconfirmationof thetermsof anypurchasecontract.

Rasor®ElettromeccanicaS.r.l. products havenot been conceivedto work in areas atriskof

explosions andathighriskof fire andtheycannot cutwetor dampmaterials. Moreover,

theycannot work incaseof rain.

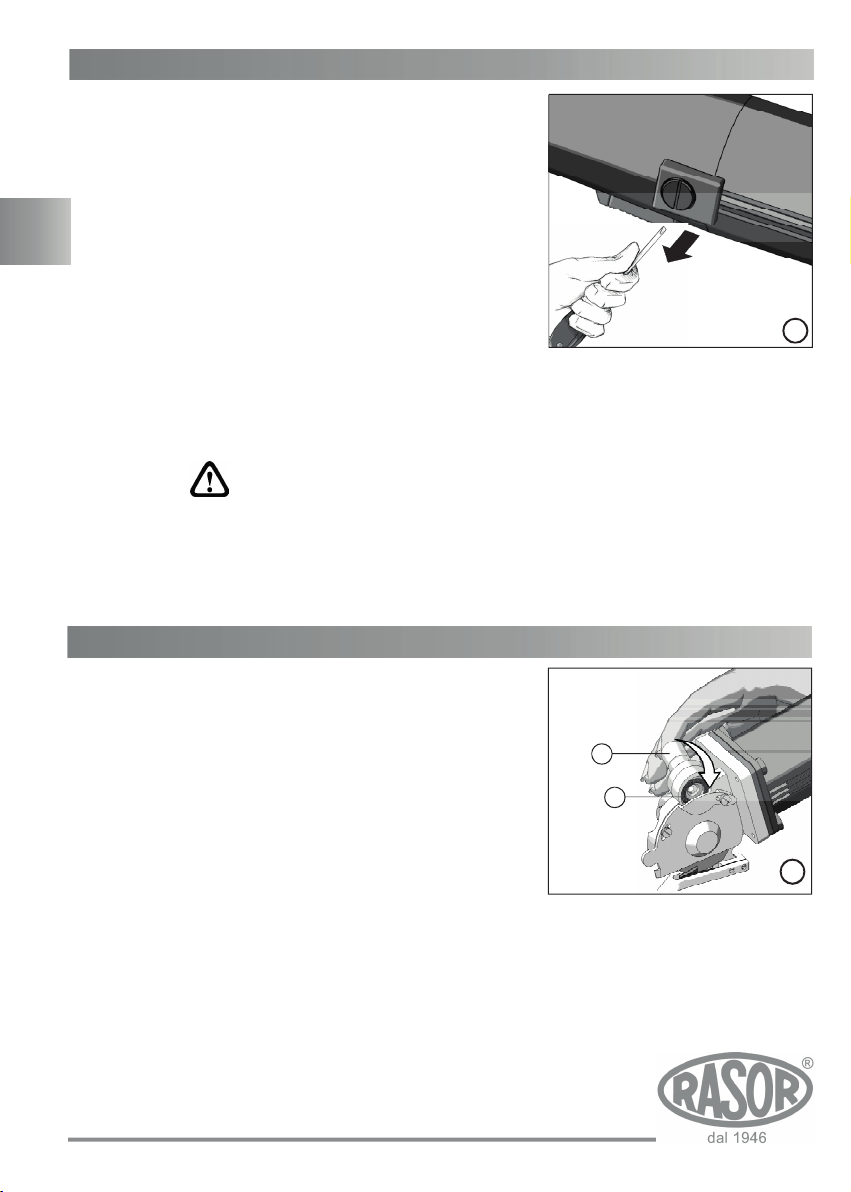

Incaseof damageor malfunction, electricscissors DS504 must not beuseduntil the

Customer Care TechnicalServicehasrepairedthem.

Theoriginalconfigurationof theelectricscissorsmustnot bechangedatall.

Onreceivingthemmakesurethesupplycorrespondstowhathasbeenordered.

In caseofnon-complianceimmediatelyinform Rasor®.

Alsomakesurethescissorshavenotbeendamagedduringtransport.

CustomerCareTechnicalService

WARNING

Theinstallerandthemaintenancemanmustknowthecontentof thismanual.Although

themain featuresoftheequipmentdescribedin thismanualarenot subjecttochange,

Rasor®ElettromeccanicaS.r.l.reservestherightto modifythecomponents,details

andaccessoriesitdeemsnecessaryto improvetheproductorto meetmanufacturing

orcommercialrequirementsatanytimeandwithoutbeingobligedto updatethis

manualimmediately.

Informativeletter

Foranyinformation,pleasecontact

RASOR®ELETTROMECCANICA S.r.l.

ViaV.Caldesi,6;20161,MILANO(MI)-ITALY

Phone:+39.02.66221231;Fax:+39.02.66221293

e-mail: info@rasor-cutters.com

web: www.rasor-cutters.com

WARNING

EN

20