Table of Contents

1Notes on the Manual ............................................................................................................................. 6

1.1 Disclaimer.......................................................................................................................................... 6

1.2 Copyright............................................................................................................................................ 6

1.3 Explanations of the Safety Instructions ............................................................................................. 7

1.4 General Safety Instructions ............................................................................................................... 8

1.5 Repairs............................................................................................................................................... 9

2Confirmation Form for the Managing Operator................................................................................ 10

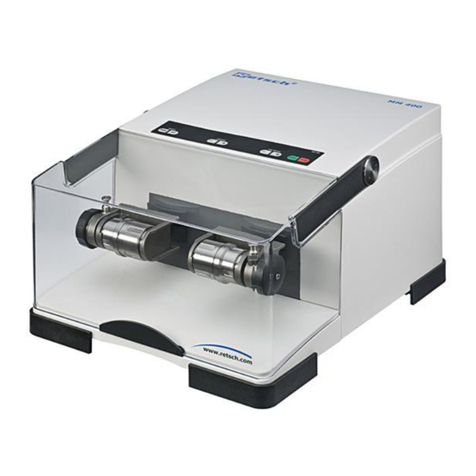

3Technical Data ..................................................................................................................................... 11

3.1 Protective Equipment....................................................................................................................... 11

3.2 Degree of Protection........................................................................................................................ 11

3.3 Emissions......................................................................................................................................... 11

3.4 Electromagnetic Compatibility (EMC).............................................................................................. 11

3.5 Rated Power.................................................................................................................................... 11

3.6 Dimensions and Weight................................................................................................................... 11

3.7 Required Floor Space...................................................................................................................... 11

3.8 Receptacle Volume.......................................................................................................................... 12

3.9 Feed Grain Size............................................................................................................................... 12

3.10 Drive power...................................................................................................................................... 12

3.11 Pressure Force ................................................................................................................................ 12

4Packaging, Transport and Installation .............................................................................................. 13

4.1 Packaging........................................................................................................................................ 13

4.2 Transport.......................................................................................................................................... 13

4.3 Temperature Fluctuations and Condensation ................................................................................. 13

4.4 Conditions for the Installation Site................................................................................................... 14

4.5 Electrical Connection....................................................................................................................... 14

4.6 Type Plate Description..................................................................................................................... 15

4.7 Removing the Transportation Aid.................................................................................................... 16

5First Commissioning........................................................................................................................... 18

6Operating the Device .......................................................................................................................... 20

6.1 Use of the Device for the Intended Purpose.................................................................................... 20

6.2 Switching On / Off............................................................................................................................ 20

6.3 Emergency Unlocking...................................................................................................................... 20

6.4 Production of a Pellet....................................................................................................................... 21

6.4.1 Free pressing / Pressing in an aluminium cup............................................................................. 21

6.4.2 Pressing in the steel ring ............................................................................................................. 27

6.4.3 Reusing the steel ring.................................................................................................................. 28

6.5 Programme Mode............................................................................................................................ 29

6.5.1 Changing programs ..................................................................................................................... 29

6.5.2 Edit program ................................................................................................................................ 30

6.5.3 Altering settings ........................................................................................................................... 31

7Error Messages and Information Notes............................................................................................ 33

7.1 Error Messages ............................................................................................................................... 33

7.2 Information Notes ............................................................................................................................ 34

8Return for Service and Maintenance................................................................................................. 35

9Cleaning, Wear and Maintenance...................................................................................................... 36

9.1 Cleaning........................................................................................................................................... 36

9.1.1 Cleaning the housing................................................................................................................... 36

9.1.2 Cleaning the pressure chamber................................................................................................... 36

9.2 Wear ................................................................................................................................................ 39

9.3 Maintenance .................................................................................................................................... 39

10 Accessories ......................................................................................................................................... 39

11 Disposal................................................................................................................................................ 40