Table of Contents

1Notes on the manual........................................................................................................................ 5

1.1 Disclaimer .................................................................................................................................... 5

1.2 Copyright...................................................................................................................................... 5

1.3 Repairs......................................................................................................................................... 6

2Safety................................................................................................................................................ 7

2.1 Explanations of the Safety Instructions.......................................................................................... 8

2.2 General Safety Instructions........................................................................................................... 9

2.3 Protective Equipment.................................................................................................................. 10

2.4 Intended use............................................................................................................................... 10

2.5 Improper use.............................................................................................................................. 10

2.6 Confirmation Form for the Managing Operator ............................................................................ 11

3Technical Data................................................................................................................................ 12

3.1 Use of the Device for the Intended Purpose................................................................................ 12

3.2 Principle of Operation ................................................................................................................. 12

3.3 Dimensions and Weight.............................................................................................................. 12

3.4 Required Floor Space................................................................................................................. 13

3.5 Installation drawing..................................................................................................................... 14

3.6 Rated Power............................................................................................................................... 15

3.7 Degree of Protection................................................................................................................... 15

3.8 Emissions................................................................................................................................... 15

3.9 Electromagnetic Compatibility (EMC).......................................................................................... 16

3.10 Feed Grain Size.......................................................................................................................... 16

3.11 Degree of hardness of the sample material................................................................................. 16

3.12 Gap width................................................................................................................................... 16

4Packaging, Transport and Installation.......................................................................................... 17

4.1 Packaging .................................................................................................................................. 17

4.2 Transport.................................................................................................................................... 17

4.3 Temperature Fluctuations and Condensation.............................................................................. 19

4.4 Conditions for the Installation Site............................................................................................... 19

4.5 Electrical Connection.................................................................................................................. 20

4.6 Type Plate Description................................................................................................................ 21

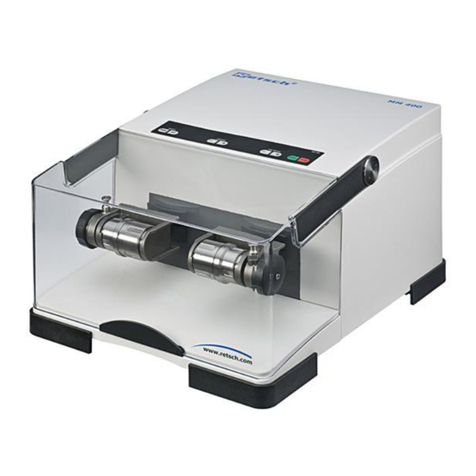

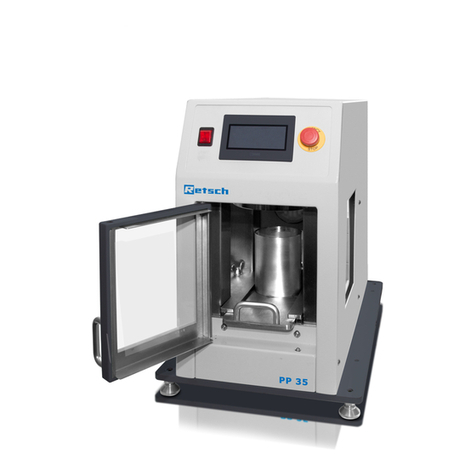

5Views of the device........................................................................................................................ 22

5.1 Front........................................................................................................................................... 22

5.2 Back........................................................................................................................................... 23

5.3 View of the control unit................................................................................................................ 24

6First Commissioning...................................................................................................................... 25

6.1 Installation of the Device............................................................................................................. 26

6.2 Establishing the power supply..................................................................................................... 27

7Operating the Device ..................................................................................................................... 28

7.1 Switching On / Off....................................................................................................................... 29

7.2 Adjusting the gap width............................................................................................................... 30

7.3 Adding sample material .............................................................................................................. 32

7.4 Removing sample material after grinding .................................................................................... 33

8Cleaning, Wear and Maintenance.................................................................................................. 35

8.1 Cleaning..................................................................................................................................... 35

8.1.1 Cleaning the machine housing................................................................................................ 36

8.1.2 Cleaning the feed hopper and grinding chamber..................................................................... 36

8.2Wear .......................................................................................................................................... 37

8.2.1 Replacing the breaking jaws ................................................................................................... 37

8.2.2 Replacing the wearing plates.................................................................................................. 40

8.3 Maintenance............................................................................................................................... 42