15.11.2006 Retsch GmbH 2 Doc. Nr. D 98.725.9998

Notes on these operating instructions......................................... 3

Warning instructions............................................................... 3

Repairs................................................................................. 3

Safety ......................................................................................... 4

Safety instructions ................................................................. 4

Safety instructions –summarised, part 1 .................................. 5

Safety instructions –summarised, part 2 .................................. 6

Confirmation ......................................................................... 7

Technical data ............................................................................ 8

Use according to the intended purpose...................................... 8

Milling cup –nominal volume................................................... 8

Maximum charged grain size ................................................... 8

Driving power........................................................................ 8

Motor speed .......................................................................... 8

Emissions ............................................................................. 9

Materials and analyses of milling tools ...................................... 9

Systems of protection ............................................................. 9

Protective equipment.............................................................. 9

Mode of operation .................................................................. 9

Machine dimensions ............................................................... 9

Required floor space............................................................... 9

Transport and installation........................................................... 10

Packing ................................................................................ 10

Transport.............................................................................. 10

Temperature variations........................................................... 10

Temperature variations........................................................... 11

Intermediate storage .............................................................. 11

Erection ................................................................................ 11

Parameters for the place of installation ..................................... 11

Ambient temperature: 5°C to 40°C........................................... 11

Atmospheric humidity ............................................................. 11

Installation height: max. 2000 m above sea level ....................... 11

Transport safety device........................................................... 11

Electrical connection............................................................... 12

Important instructions for electrical connection .......................... 13

Serial interfaces..................................................................... 13

Operation ................................................................................... 14

Connecting the power supply ................................................... 14

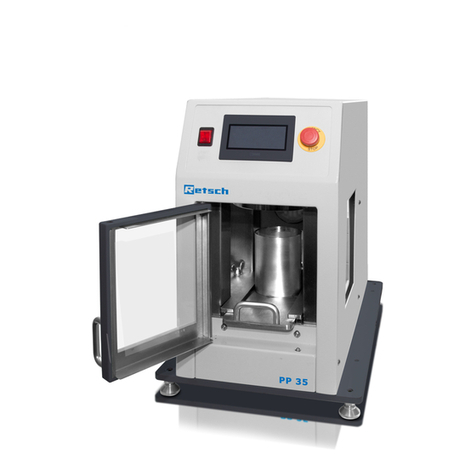

Opening / closing / emergency unlocking .................................. 14

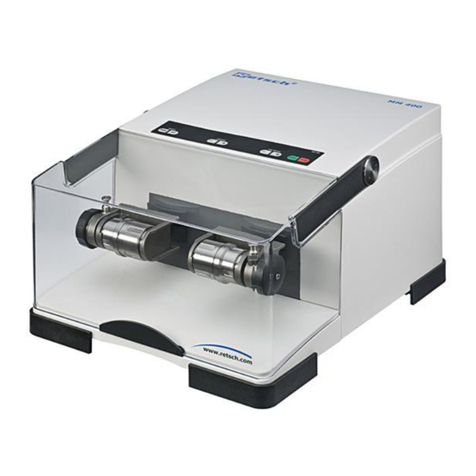

Insertion and clamping of the milling set of the RS200 ................ 15

Preparation of the milling process............................................. 16

Before starting the RS200 ....................................................... 18

Suitable milling sets for the RS200 ........................................... 18

Milling set filling level ............................................................. 18

Guide values for material quantity and grain size ....................... 18

Cleaning the milling cups ........................................................ 19

Drying the milling cups ........................................................... 19

Operation via the display unit of the RS200 ............................... 20

Symbols in the display unit...................................................... 20

Setting possibilities via the display menu .................................. 21

Languages ............................................................................. 21

False language selection .......................................................... 21

Manual operation .................................................................... 21

Milling programme .................................................................. 21

Milling time ............................................................................ 21

Speed ................................................................................... 21

Speed with agate .................................................................... 22

Starting time .......................................................................... 23

Opening automatic .................................................................. 23

Warning sound ....................................................................... 23

Service .................................................................................. 23

Contrast / Brightness............................................................... 24

Date / Time............................................................................ 24

Stand-by monitor.................................................................... 24

Fault signals in the display ......................................................... 25

F02 to F13 ............................................................................ 25

General....................................................................................... 26

Cleaning ............................................................................... 26

Maintenance.......................................................................... 26

Maintenance of the rubber springs............................................ 26

Opening the cover.................................................................. 27

Wearing parts........................................................................ 27

Copyright.............................................................................. 27

Alterations ............................................................................ 27