Table of contents

1 Introduction...................................................................................................4

1.1 Validity of these operating instructions.........................................................4

1.2 Target group for these operating instructions ..............................................4

1.3 Compliance with the operating instructions..................................................4

1.4 EC and VDE directives.................................................................................5

1.5 Accident prevention (UVV)...........................................................................5

2 For your safety .............................................................................................7

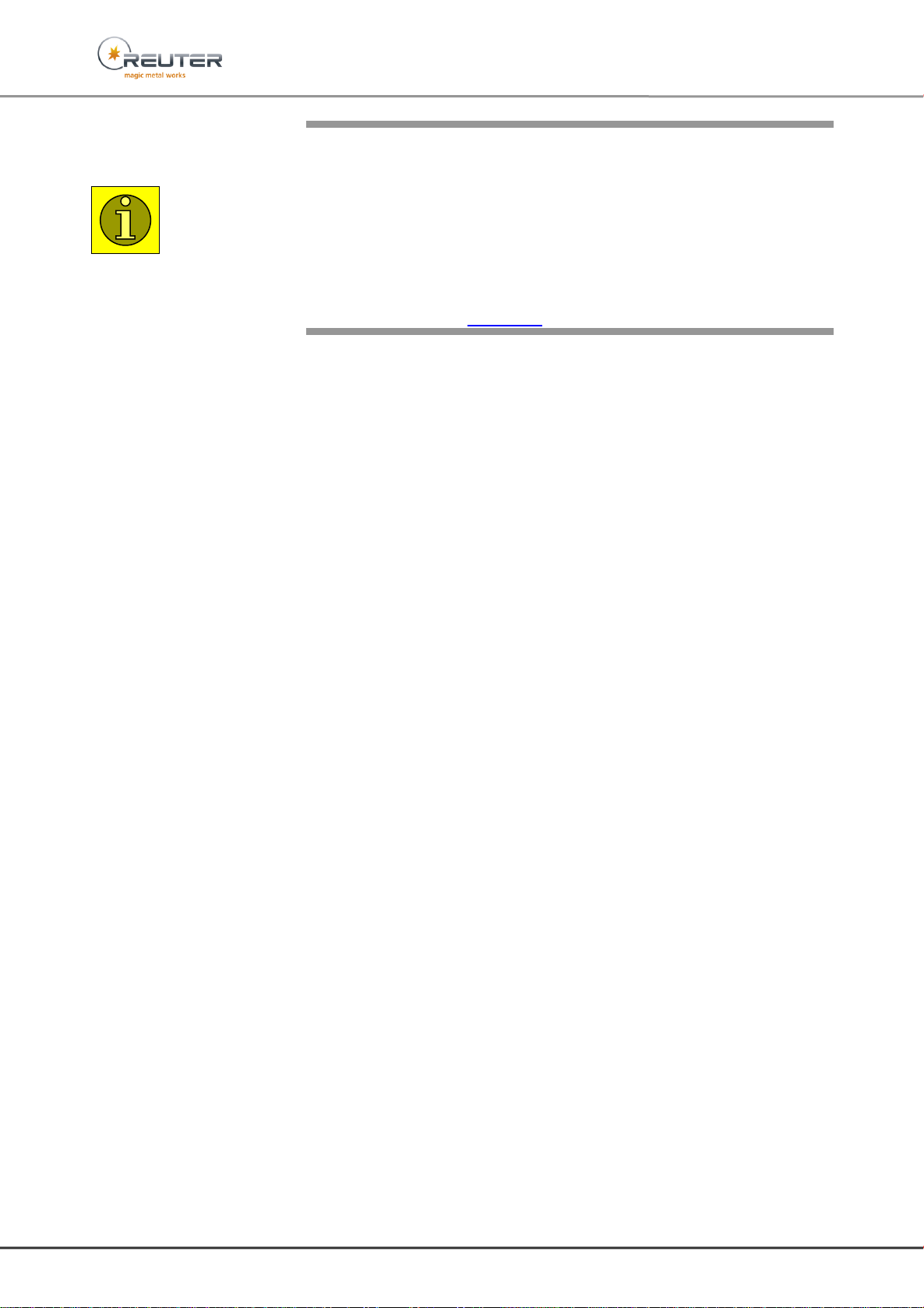

2.1 Convention ...................................................................................................7

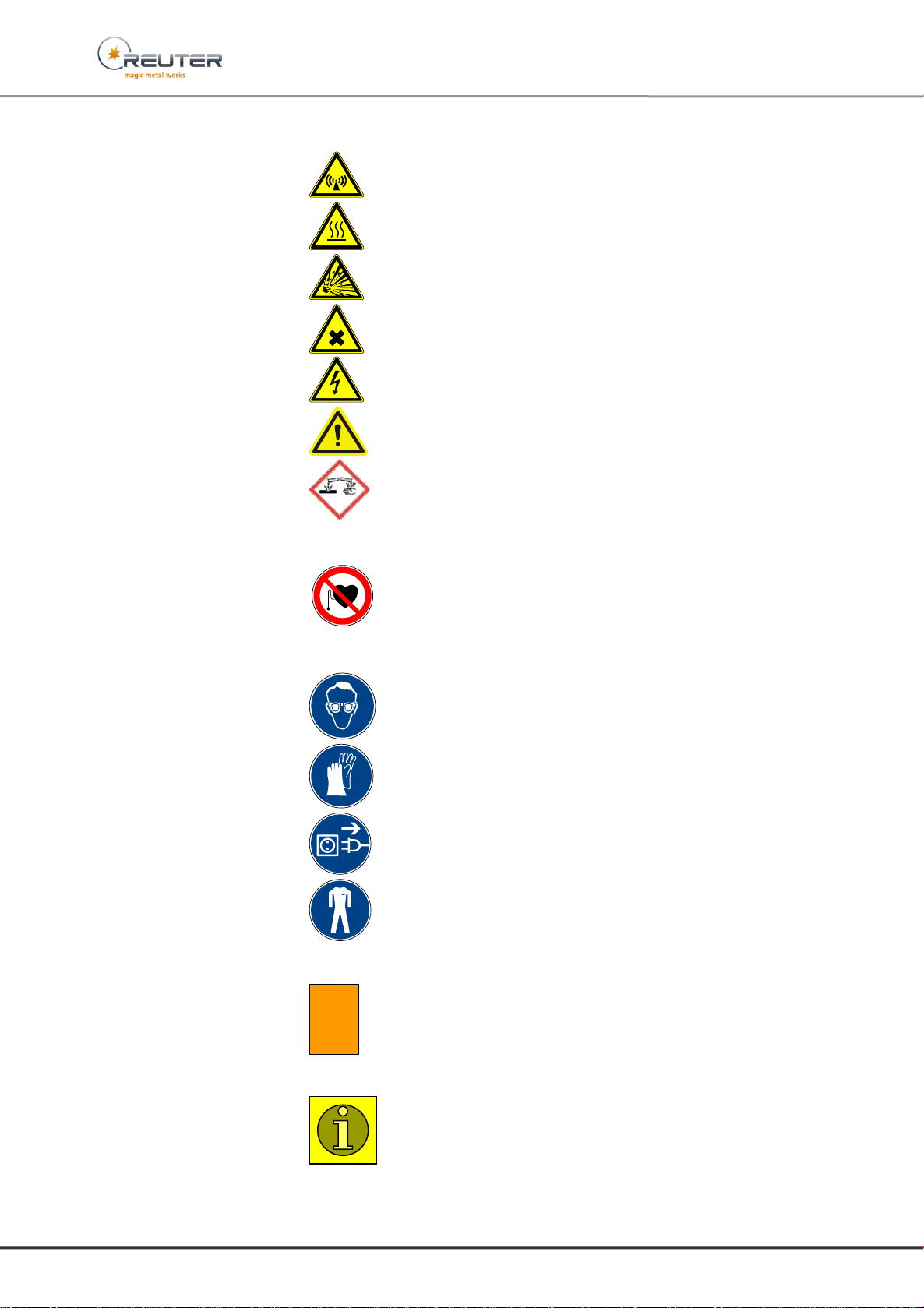

2.1.1 Pictograms....................................................................................................7

2.1.2 Presentation .................................................................................................7

2.1.3 Warning signs...............................................................................................8

2.1.4 Prohibition signs...........................................................................................8

2.1.5 Mandatory signs...........................................................................................8

2.1.6 Information signs..........................................................................................8

2.2 Safety measures in the event of failure........................................................9

2.2.1 Safety-relevant environmental conditions ....................................................9

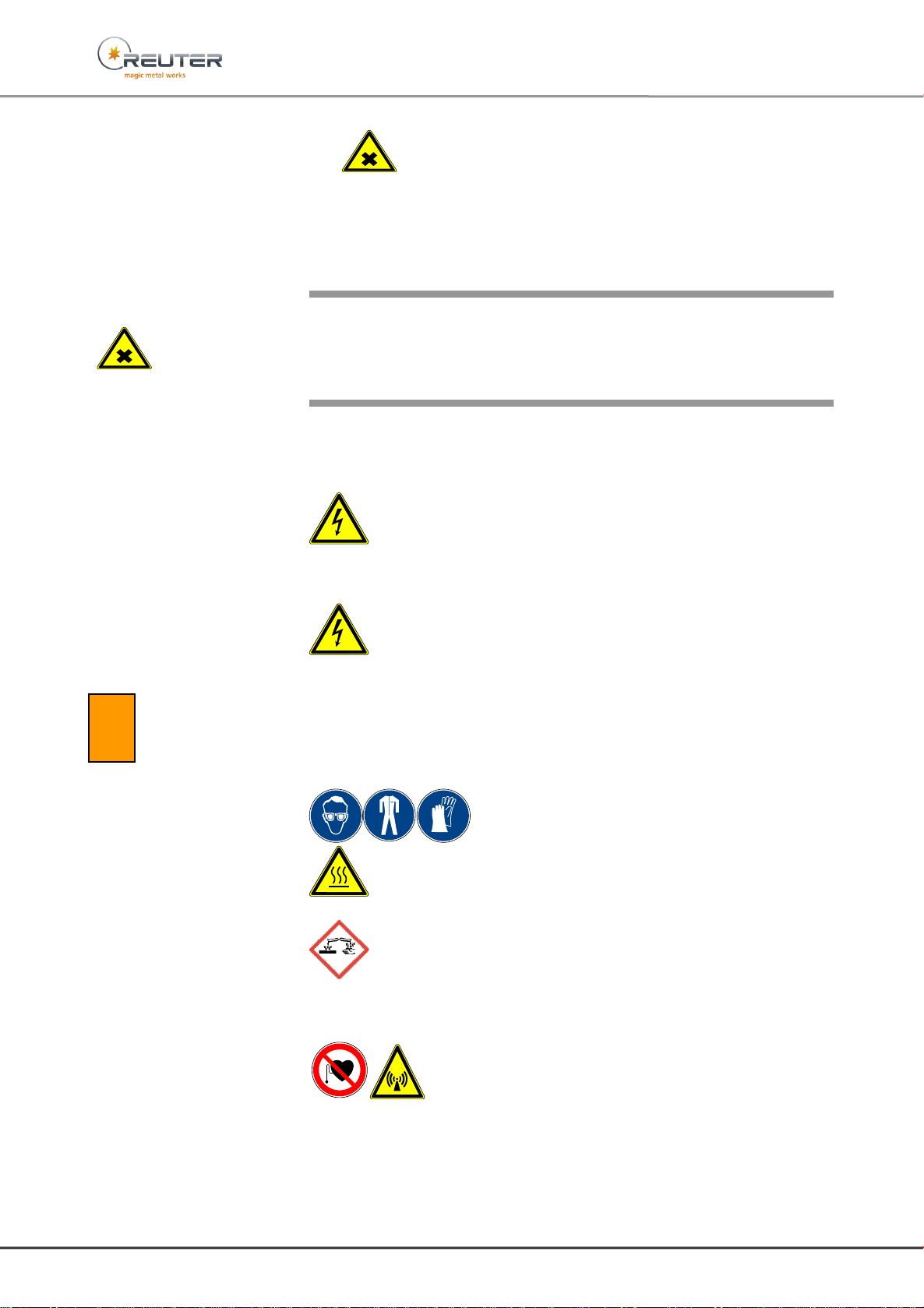

2.3 Potential sources of danger and protective measures...............................10

2.3.1 Potential sources of danger........................................................................10

2.3.2 Protection measures ..................................................................................11

2.3.3 Before starting work, check........................................................................12

2.4 Potential misuses .......................................................................................12

2.5 Residual risks.............................................................................................12

3 Demands on personnel and operators.......................................................13

3.1 Users..........................................................................................................13

3.2 Operator .....................................................................................................13

4 Warranty and liability..................................................................................13

4.1 Material defects..........................................................................................14

5 Technical terms..........................................................................................14

6 Delivery, in-house transport, unpacking.....................................................15

6.1 Delivery.......................................................................................................15

6.2 Unloading ...................................................................................................16

6.3 In-house transport ......................................................................................16

6.4 Unpacking...................................................................................................16

6.4.1 Opening the Euro plastic box.....................................................................16

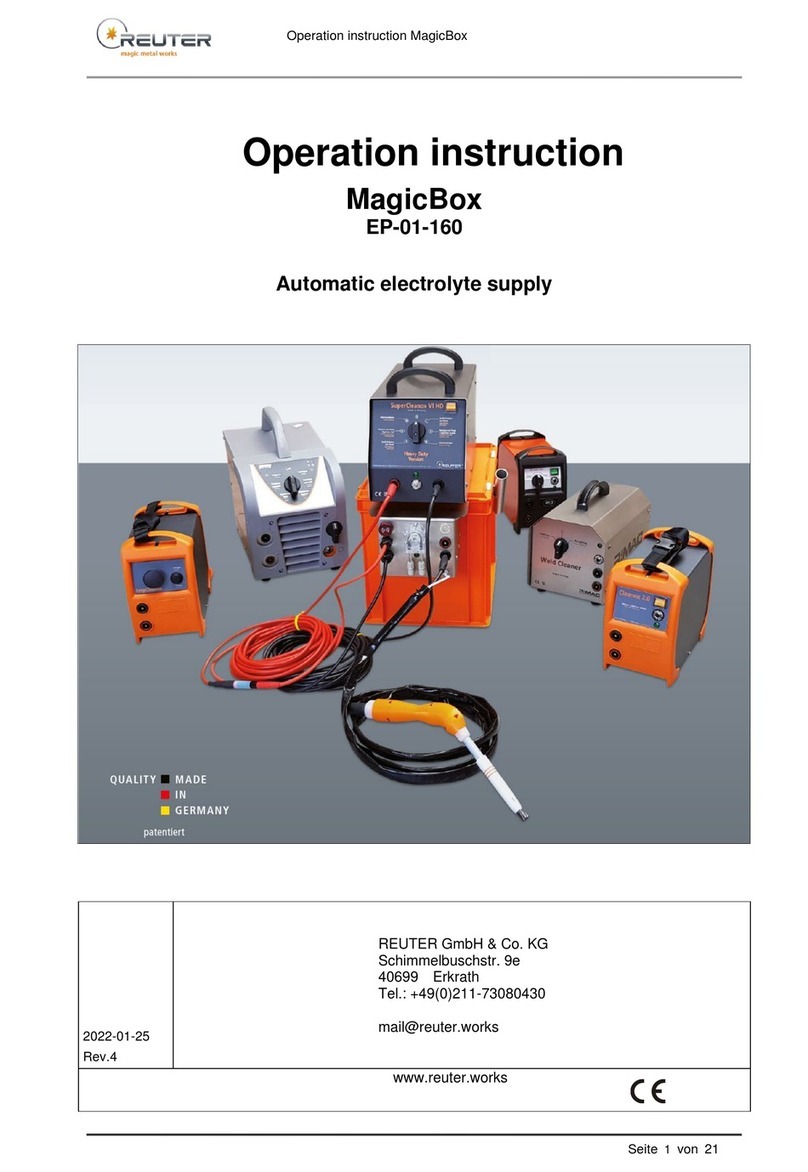

7 Scope of delivery of the "Cleanox1" appliance set.....................................17

7.1 Delivery list, “Cleanox”cleaning set ............................................................17

8 Storage requirements.................................................................................20

9 Installation conditions.................................................................................20

9.1 Safety .........................................................................................................20

10 Decommissioning / storage........................................................................20

11 Storage.......................................................................................................20

12 Appliance technology .................................................................................21

12.1 Applications................................................................................................21

13 Controls and operating elements on the front panel..................................22

13.1 Automatic circuit breaker (overload FUSE)................................................22

13.2 Elements on the back panel.......................................................................23

14 Accessories................................................................................................24

14.1 Teflon handle with cable and plug..............................................................24

14.2 Earth clip with cable and plug.....................................................................24

14.3 Carbon fibre brush L...................................................................................25

14.4 Assembly carbon fibre brush XL / Teflon handle .......................................25

14.4.1 Adjusting the Teflon sliding sheath ............................................................26

14.5 Electrolyte...................................................................................................27

14.5.1 Transferring into the wide-mouth container................................................27

14.5.2 Information concerning non-toxicity ...........................................................28

14.5.3 Information concerning the scope of delivery.............................................29

15 Commissioning...........................................................................................29

16 Connection .................................................................................................29

16.1 Mains connection .......................................................................................29

16.2 Earth clip connection..................................................................................30