Contents

1 Introduction..............................................................................................3

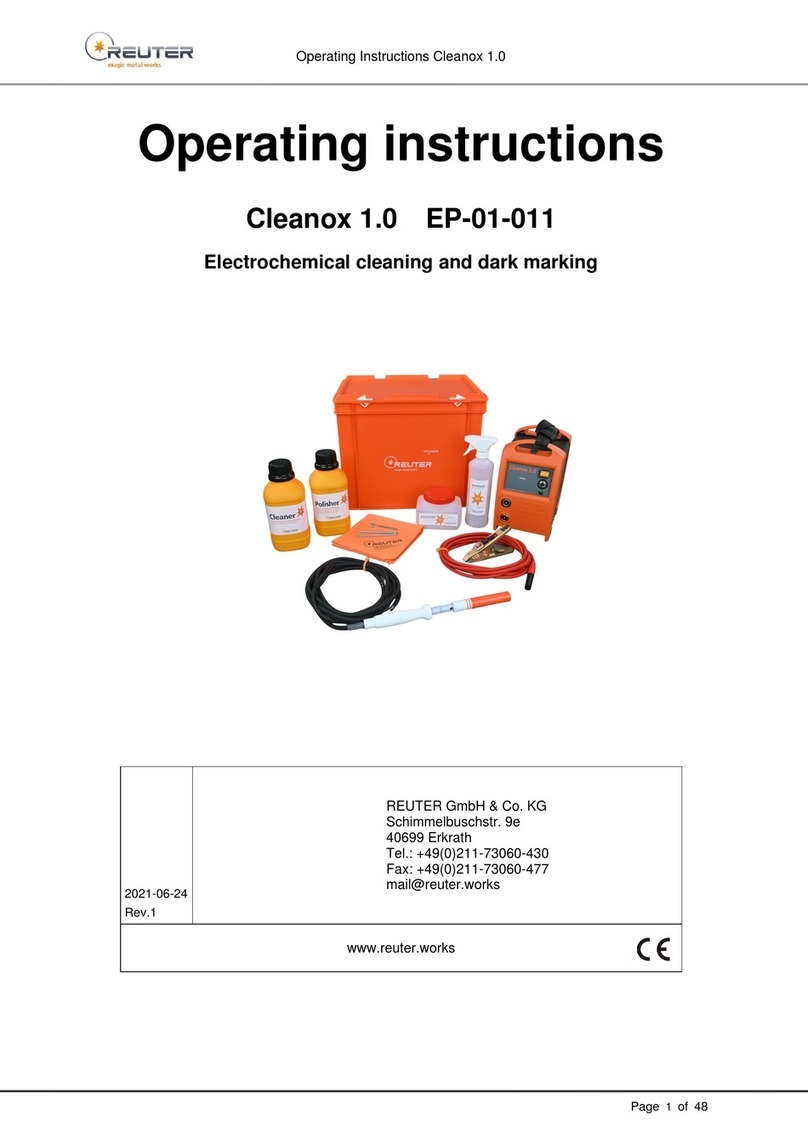

2 Delivery....................................................................................................4

2.1 Opening the Euro plastic box..................................................................4

3 Getting ready to start...............................................................................4

3.1 Opening MagicBox..................................................................................4

4 Description of the control, operating and connection elements ..............5

4.1 Connection for hose package .................................................................5

4.1.1 Removing blind plug / electrolyte supply hose........................................5

4.1.2 Fasten the blind plug / electrolyte supply hose .......................................6

4.2 Monitoring electrolyte level......................................................................6

4.3 Manuel supply of electrolyte....................................................................6

4.4 Electrolyte pump......................................................................................7

5 Connect machine / accessories ..............................................................7

5.1 Cleaning machine....................................................................................7

5.2 AutoFeed.................................................................................................7

5.3 Electrolyte canister..................................................................................8

5.4 Autofeed hose package...........................................................................9

5.4.1 Change brush........................................................................................10

5.4.2 Adjusting the Teflon sleeve...................................................................11

5.4.3 Connection of earth clamp - workpiece.................................................11

5.4.4 Tip for setting up....................................................................................11

6 Working with the AutoFeed Brush.........................................................12

7 Service Work.........................................................................................13

7.1 Replace the electrolyte canister............................................................13

7.2 Fill the electrolyte canistern...................................................................14

7.3 Measures when the device is not used for a long period......................15

7.4 Change the connection hose with sieve and weight.............................16

8 Spar Parts .............................................................................................17

8.1 AutoFeed-Hose ...................................................................................17

8.1.1 Change/Renew the O-Rings .................................................................18

8.2 Pump housing .......................................................................................19

8.3 Pump housing lower part.......................................................................20

9 EC –Declaration of Conformity.............................................................21