REV Robotics SPARK User manual

REV-11-1200-UM-00 Copyright © 2016 REV Robotics, LLC

fg

SPARK MOTOR CONTROLLER

USER'S MANUAL

REV-11-1200-UM-00 Copyright © 2016 REV Robotics, LLC 2

TABLE OF CONTENTS

1SPARK OVERVIEW ................................................................................................................................................................. 4

1.1 FEATURE SUMMARY .................................................................................................................................................... 5

1.2 KIT CONTENTS .............................................................................................................................................................. 5

1.3 SPECIFICATIONS........................................................................................................................................................... 6

2FEATURE DESCRIPTION ........................................................................................................................................................ 7

2.1 POWER AND MOTOR CONNECTIONS ......................................................................................................................... 7

2.1.1 SCREW TERMINALS ................................................................................................................................................. 7

2.1.2 MOTOR OUTPUT ....................................................................................................................................................... 8

2.1.3 POWER INPUT ........................................................................................................................................................... 8

2.1.4 CONNECTING MOTOR AND POWER WIRES ........................................................................................................... 8

2.2 SPEED AND DIRECTION CONTROL.............................................................................................................................. 9

2.2.1 SERVO-PWM CONNECTION ..................................................................................................................................... 9

2.2.2 CONTROLLING MOTOR SPEED AND DIRECTION ................................................................................................... 9

2.3 HEAT MANAGEMENT ................................................................................................................................................. 10

2.4 LIMIT SWITCH INPUTS ............................................................................................................................................... 11

2.4.1 LIMIT SWITCH OPERATION.................................................................................................................................... 11

2.4.2 LIMIT SWITCH WIRING ........................................................................................................................................... 11

2.5 OPERATING MODES.................................................................................................................................................... 12

2.5.1 BRAKE/COAST MODE............................................................................................................................................. 12

2.5.2 CALIBRATION .......................................................................................................................................................... 13

2.5.3 FACTORY RESET ..................................................................................................................................................... 13

2.6 STATUS LED ................................................................................................................................................................ 14

APPENDIX A DIMENSIONS................................................................................................................................................... 15

APPENDIX B THERMAL DATA.............................................................................................................................................. 16

APPENDIX C LINEARITY DATA............................................................................................................................................. 17

APPENDIX D SCHEMATIC..................................................................................................................................................... 18

REV-11-1200-UM-00 Copyright © 2016 REV Robotics, LLC 3

LIST OF FIGURES

Figure 1-1 SPARK Motor Controller.............................................................................................................................................. 4

Figure 2-1 Power and Motor Connections ................................................................................................................................... 7

Figure 2-2 Servo-PWM Connection............................................................................................................................................... 9

Figure 2-3 Heat Sink .................................................................................................................................................................... 10

Figure 2-4 Limit Switch Inputs .................................................................................................................................................... 11

Figure 2-5 Mode Button............................................................................................................................................................... 12

Figure 2-6 LED Status Codes ...................................................................................................................................................... 14

LIST OF TABLES

Table 1-1 Electrical Specifications ............................................................................................................................................... 6

Table 1-2 Servo-PWM Input Specifications ................................................................................................................................. 6

Table 1-3 Limit Switch Input Specifications ................................................................................................................................ 6

Table 1-4 Mechanical Specifications ........................................................................................................................................... 6

Table 2-1 Compatible Crimp-terminal Sizes................................................................................................................................. 7

Table 2-2 Input Pulse Mapping ..................................................................................................................................................... 9

REV-11-1200-UM-00 Copyright © 2016 REV Robotics, LLC 4

1SPARK OVERVIEW

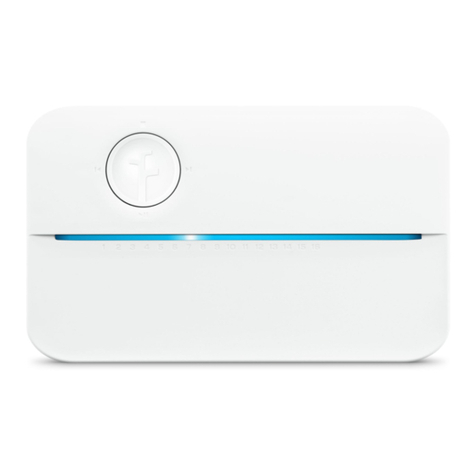

The REV Robotics SPARK Motor Controller is 12V 60A PWM-controlled brushed DC motor controller designed for

FIRST® Robotics Competition robots.

The Spark features 60A continuous current with passive cooling, bi-directional limit switch inputs for smart mechanism

control, an RGB LED status indicator, and a button-activated brake/coast mode.

Figure 1-1 SPARK Motor Controller

REV-11-1200-UM-00 Copyright © 2016 REV Robotics, LLC 5

1.1 FEATURE SUMMARY

The SPARK Motor Controller provides the following features:

RC servo style PWM control interface

Passive Cooling

oNo fans required

Synchronous rectification

oReduces heat generation

Limit switch inputs

oStops forward and/or reverse motion automatically

oNo programming required

Brake/Coast modes

Calibration

oFactory calibrated to 1ms - 2ms input signal

oUser calibratable

Integrated cable retention for PWM port

Clamping screw terminals

oBetter contact area and retention

oCompatible with #6 and #8 "yellow" ring terminals

RGB Status LED

oDetailed mode and operation feedback

1.2 KIT CONTENTS

The following items are included with each SPARK Motor Controller:

1 - SPARK Motor Controller

1 - PWM Cable - 36" - 22 AWG

2 - Extra terminal screws - M3

REV-11-1200-UM-00 Copyright © 2016 REV Robotics, LLC 6

1.3 SPECIFICATIONS

The following tables provide the operating and mechanical specifications for the SPARK motor controller.

CAUTION

DO NOT exceed the maximum supply voltage or maximum current rating. Doing so will cause permanent damage to the

SPARK and will void the warranty.

Table 1-1 Electrical Specifications

Parameter

Min

Typ

Max

Units

Supply voltage range (VIN)

5.5

12

24

V

Supply voltage absolute maximum

-

-

30

V

Continuous output current

-

-

60a

A

Maximum output current - for 2 seconds

-

-

100

A

Output voltage range

- VIN

+VIN

V

Output frequency

-

15.625

-

kHz

a. Continuous operation at 60A may produce high temperatures on the heat sink. Caution should be taken when handling a

SPARK if it has been running at higher current levels for an extended period of time.

Table 1-2 Servo-PWM Input Specifications

Parameter

Min

Typ

Max

Units

Default full-reverse input pulsea

-

1000

-

µs

Default neutral input pulseb

-

1500

-

µs

Default full-forward input pulsec

-

2000

-

µs

Input pulse width range

500

-

2500

µs

Input frequency

16

50

200

Hz

Input timeoutd

-

65.5

-

ms

Input deadbande

-

40

-

µs

Digital high-level input current

7

-

25

mA

a. Full-reverse corresponds to negative output voltage (-VIN).

b. Neutral corresponds to zero output voltage (0V) and is either braking or coasting depending on the current mode.

c. Full-forward corresponds to positive output voltage (+VIN).

d. If a valid pulse isn't received within the timeout period, the SPARK will disable its output.

e. Input deadband is added to each side of the neutral pulse width. Within the deadband, output state is neutral.

Table 1-3 Limit Switch Input Specifications

Parameter

Min

Typ

Max

Units

Digital low-level input voltagea

-0.3

-

0.8

V

Digital high-level input voltageb

2.0

5.0

5.3

V

Pull-up resistor

16

35

200

kΩ

Response time

-

-

62.5

ms

a. Disables motion in corresponding direction.

b. Enables motion in corresponding direction.

Table 1-4 Mechanical Specifications

Parameter

Value

Dimensions

2.860" x 1.875" x 0.868"

Weight

74g / 2.61oz

Mounting hole size

#10 clearance / 0.200"

Terminal screw size

M3

REV-11-1200-UM-00 Copyright © 2016 REV Robotics, LLC 7

2FEATURE DESCRIPTION

The REV Robotics SPARK Motor Controller includes a range of features designed specifically for use on FIRST®

Robotics Competition robots. Each feature is described in detail throughout the following sections.

2.1 POWER AND MOTOR CONNECTIONS

The SPARK is designed to drive 12V brushed DC motors at currents up to 60A continuously. Power and motor

connections are made through the two sets of screw terminals built into the SPARK. Figure 2-1 shows these

connections in detail.

Figure 2-1 Power and Motor Connections

2.1.1 SCRE W TERM IN ALS

The SPARK has four M3 sized screw terminals; two each for power and motor connections. Each screw has a clamping

washer that improves the contact area and clamping force compared to plain screw heads. Table 2-1 lists the

recommended crimp-terminal sizes and styles.

Table 2-1 Compatible Crimp-terminal Sizes

Terminal Screw/Stud Size

Standard Color

Ring

Fork

#6

Yellow

Compatible

Compatible

#8

Yellow

Compatible

Not Recommended

M3

Yellow

Compatible

Compatible

REV-11-1200-UM-00 Copyright © 2016 REV Robotics, LLC 8

2.1.2 M O TOR OU TPUT

Motor output terminals are located above the SPARK logo and are marked with raised lettering. A raised "+" and "−" sign

indicate the polarity of the motor terminals. See Figure 2-1 for more details.

It is recommended to follow a polarity convention when connecting motors to multiple SPARKs so that each motor

responds in a predictable manner to the same input signals. When the SPARK is driving the output in the "forward"

direction, the output polarity is positive from M+ to M−. When driving in "reverse" the output polarity is reversed.

2.1.3 POWER INPUT

Power input terminals are located below the SPARK logo and are marked with raised lettering. A raised "+" and "−" sign

indicate the polarity of the power terminals.

The SPARK is intended to operate in a 12V DC robot system, however, it is compatible any DC power source between

5.5V and 24V.

When using high current motors, it is recommended to use a power source that is capable of handling large surge

currents, e.g. a 12V lead-acid battery. If the supply voltage drops below 5.5V the SPARK will brown out, resulting in a

power loss to the motor. It is also recommended to incorporate a fuse or auto-resetting circuit breaker in series with the

SPARK between it and the power source to prevent exceeding the maximum current rating.

2.1.4 CON NECTING MOTOR AN D PO WER W IRES

Using an appropriate wire gauge for the expected current draw, tightly crimp either a ring or fork terminal on the wire.

Insert the crimped terminal into the screw terminal and tighten the screw. Give the wire a tug to make sure it is secure.

Figure 2-1 shows both motor and power wires connected to the SPARK.

CAUTION

DO NOT swap the motor and power connections. This can result in uncontrolled motor operation, can permanently

damage the SPARK, and will void the warranty.

CAUTION

DO NOT exceed the maximum supply voltage of 30V. Doing so will cause permanent damage to the SPARK and will void

the warranty.

CAUTION

DO NOT exceed the maximum current ratings of 60A or 100A for 2 seconds. Doing so will cause permanent damage to

the SPARK and will void the warranty.

CAUTION

As with any electrical component, make all connections with power turned off. Connecting the SPARK to a powered

system may result in unexpected behavior and may pose a safety risk.

REV-11-1200-UM-00 Copyright © 2016 REV Robotics, LLC 9

2.2 SPEED AND DIRECTION CONTROL

A brushed DC motor's unloaded rotation speed is determined by voltage that is applied to it while the direction of

rotation is determined by the polarity of that voltage. The magnitude and polarity of the SPARK output voltage is

controlled by sending it a standard servo-style PWM signal. The following sections describe this interface in detail.

2.2.1 SER VO -PWM CONNE CTION

The SPARK accepts a standard 3-wire servo/PWM cable in the port marked PWM in raised lettering. Please refer to the

connection diagram in Figure 2-2 or the SPARK housing for polarity indicators. Align the ground/negative wire with the B

marking on the case. This wire is usually black, but may be brown in some cases. The signal wire should be closest to

the SPARK logo on the heat sink. This wire is usually white but may also be yellow or orange.

Figure 2-2 Servo-PWM Connection

The plastic surrounding the PWM port was designed provide cable retention by exerting pressure on the housing of a

standard 3-wire cable housing. Retention effectiveness may vary depending on the cable being used.

2.2.2 CONTRO LL IN G MO T OR SPE ED AN D DIRE CTION

The SPARK responds to a factory default pulse range of 1000µs to 2000µs. These pulses correspond to full reverse and

full forward rotation, respectively, with 1500µs (±40 µs deadband) as the neutral position, i.e., no rotation. The spark can

be calibrated to respond to a different pulse range, see section 2.5.2 CALIBRATION. Table 2-2 describes how the pulse

range maps to the output voltage, motor speed, and motor direction.

Table 2-2 Input Pulse Mapping

For input pulse p

Motor Speed and Direction

Full Reverse

Prop. Reverse

Neutral

Prop. Forward

Full Forward

Output voltage VOUT (V)

VOUT = −VIN

−VIN < VOUT < 0

VOUT = 0

0 < VOUT < +VIN

VOUT = +VIN

Default pulse width (µs)

p ≤ 1000

1000 < p < 1460

1460 ≤ p ≤ 1540

1540 < p < 2000

2000 ≤ p

Maximum pulse range (µs)

500 ≤ p ≤ 2500

REV-11-1200-UM-00 Copyright © 2016 REV Robotics, LLC 10

The output voltage seen by the motor is proportionally related to the input pulses. A change in pulse results in a

proportional change in motor speed. The approximate output voltage is determined by the following equations:

PMAX = Configured maximum pulse width in µs (default 2000)

PNEUTRAL = Configured neutral pulse width in µs (default 1500)

PMIN = Configured minimum pulse width in µs (default 1000)

p= Input pulse width in µs

VOUT = Approximate output voltage seen by the motor

2.3 HEAT MANAGEMENT

The SPARK uses a method called synchronous rectification when switching the motor output in order to minimize the

heat generated by its H-bridge. Some heating is unavoidable, so an aluminum heat sink passively dissipates heat into

the surrounding atmosphere.

Figure 2-3 Heat Sink

As seen in Figure 2-3, the heat sink is located at the center of the SPARK. For most applications, a cooling fan isn't

necessary, however, airflow should be kept in mind when using the SPARK in high-load applications. The heat sink is

electrically isolated from the SPARK circuit board and components. APPENDIX B shows the temperature at various

internal and external locations on the SPARK while it was under a 40A load for 300 seconds.

CAUTION

Under heavy loading conditions and prolonged periods of high current the SPARK heat sink may become hot. Use

caution when handling a SPARK that has been used under heavy loading conditions.

REV-11-1200-UM-00 Copyright © 2016 REV Robotics, LLC 11

2.4 LIMIT SWITCH INPUTS

The SPARK has two limit switch inputs that, when triggered, can independently prevent motion in both the forward and

reverse directions.

2.4.1 LIM IT SWIT CH OPER ATION

When the signal (s) pin is shorted to the ground (-) pin, the SPARK will override an input command for the corresponding

direction and force the SPARK to its neutral state. The STATUS LED will turn white and pulse the corresponding

direction color when either of the two limits are triggered and overriding the input command. See section 2.6 STATUS

LED for more information.

For example, if the Forward Limit Switch is triggered, a forward command from the PWM input is overridden and the

output is forced into its neutral state. However, reverse commands are still accepted and sent to the output.

2.4.2 LIM IT SWIT CH WIRI NG

The SPARK has two 3-pin connectors that can accept standard 3-wire sensor cables. The center pin is not used for the

limit switch inputs. Figure 2-4 shows the locations of the Forward and Reverse ports and an example connection

diagram. It is recommended to use a limit switch that is Normally Open (NO). When it is pressed, the switch closes and

shorts the signal (s) and ground (-) pins.

Figure 2-4 Limit Switch Inputs

REV-11-1200-UM-00 Copyright © 2016 REV Robotics, LLC 12

2.5 OPERATING MODES

The SPARK has three operating modes consisting of Brake Mode, Coast Mode, and Calibration Mode. It can also be

reset to the factory defaults.

The MODE button is used to switch between the three modes and to reset the SPARK to its factory defaults. It is located

near the power input terminals and is labeled as MODE in raised lettering on the SPARK housing. See Figure 2-5.

Figure 2-5 Mode Button

Use a straightened paper clip or other small implement to press the Mode Button.

The following sections describe each operating mode in detail.

2.5.1 BR A KE/ COAS T MOD E

When not driving the motor, the SPARK will short the motor terminals to dissipate electrical energy, effectively braking

the motor. Alternatively, the SPARK can be put in a Coast Mode which allows the motor to spin down at its own rate.

Press and release the MODE button to toggle between brake and coast mode. When in Brake Mode (default), the Status

LED will display a solid or blinking blue color. When in Coast Mode, the Status LED will display a solid or blinking yellow

color. See section 2.6 STATUS LED for more information.

This mode is saved in memory and persists through a power cycle.

REV-11-1200-UM-00 Copyright © 2016 REV Robotics, LLC 13

2.5.2 CAL IBRATIO N

The default input pulse width times should be compatible with most controllers. However, if a different mapping is

desired, the SPARK can be calibrated as follows:

The SPARK must be receiving a signal to begin calibration. It is recommended that the motor be disconnected while

calibrating to prevent unexpected movement.

1. Press and hold the MODE button for 3 seconds. The STATUS LED will start to blink white.

2. Sweep the input signal through the entire desired range.

3. Return the signal to the desired neutral value.

4. Release the MODE button.

If the calibration routine was successful, the status LED will blink white and green for several seconds while the SPARK

immediately begins responding to the new signal range.

If the calibration routine was unsuccessful, the Status LED will blink white and red and the previous values are restored.

Check that the signal didn't violate the timing constraints and/or the neutral value wasn't too close to the full forward or

full reverse values. See section 2.6 STATUS LED for more information.

Calibration values are saved to memory and persist through a power cycle.

2.5.3 FA CTORY R ES ET

The SPARK can be reset to its factory default settings with the following procedure:

1. Disconnect power to the SPARK

2. Press and hold the MODE button

3. Reconnect power while still holding the button

4. The Status LED will illuminate white

5. Release the button

The Status LED will blink white and green indicating that the factory defaults have been restored. See section 2.6

STATUS LED for more information.

REV-11-1200-UM-00 Copyright © 2016 REV Robotics, LLC 14

2.6 STATUS LED

The SPARK can display information about its current mode of operation via its tri-colored STATUS LED. The STATUS

LED is located next to the motor output terminals and is labeled as STATUS with raised lettering on the SPARK housing.

Figure 2-6 shows the status codes associated with each operating state of the SPARK.

LED Status Code

Time Scale

1 second

1 second

State

Normal Operation

No Signal

Brake

Coast

Full Forward

Proportional Forward

Neutral

Brake

Coast

Proportional Reverse

Full Reverse

Forward Limit Tripped

Reverse Limit Tripped

Calibration

Calibration Mode

Successful Calibration

Failed Calibration

Factory Reset

Mode button held during power up

Mode button released

Reset to Factory Defaults

Figure 2-6 LED Status Codes

REV-11-1100-UM-00 Copyright © 2016 REV Robotics, LLC 15

APPENDIX A DIMENSIONS

All dimensions are in inches.

REV-11-1100-UM-00 Copyright © 2016 REV Robotics, LLC 16

APPENDIX B THERMAL DATA

REV-11-1100-UM-00 Copyright © 2016 REV Robotics, LLC 17

APPENDIX C LINEARITY DATA

The following data was taken with a free spinning CIM motor and a 12V power source. The flat zone in the middle represents the 40µs input deadband on either

side of the neutral pulse width.

REV-11-1200-UM-00 Copyright © 2016 REV Robotics, LLC 18

APPENDIX D SCHEMATIC

Appendix D shows the schematic for the REV Robotics SPARK Motor Controller.

B

REV-11-1200

SPARK Motor Controller

60A Continuous, 12V

Brushed DC Motor Controller

DAY

WWW.REVROBOTICS.COM

PROJECT

DESCRIPTION

FILENAME

DESIGNER

REVISION

DATE

PART NO.

SHEET

1

1

OF

RR-SPARK-BD-B.sch

1/9/2016

OPTICAL ISOLATOR

MICROCONTROLLER

PROGRAMMING PADS

5V REGULATOR

BUS CAPACITORS

H-BRIDGE

GATE DRIVER

STATUS LED

MODE BUTTON

PWM INPUT

LIMIT SWITCH INPUTS

POWER TERMINALS

MOTOR TERMINALS

16

RA0/ICSPDAT

15

RA1/ICSPSCLK

14

RA2

1

/MCLR/VPP/RA3

20

RA4

19

RA5

13

RC0

12

RC1

11

RC2

4

RC3

3

RC4

2

RC5

5

RC6

6

RC7

10

RB4

9

RB5

8

RB6

7

RB7

18

VDD

17

VSS

U1

PIC16F1828-I/GZ

21

VDD

7

VREG

20

AHI

19

ALO

18

BHI

17

BLO

24

FAULT

1

RESET

23

RDEAD

22

AGND

12

VBB

8

CA

9

GHA

10

SA

11

GLA

3

GLB

4

SB

5

GHB

6

CB

14

CP1

13

CP2

2

GND

15

GND

16

GND

25

PAD

U2

A4940

5

1

2

3

4

Q1

5

1

2

3

4

Q2

5

1

2

3

4

Q3

5

1

2

3

4

Q4

RV1

RV2

R1

27

R2

27

R3

27

R4

27

C1

1.0uF

C2

1.0uF

C4

0.1uF

C3

1.0uF

R5

82.0K

R6

10K

C6

0.1uF

C5

10uF

1

ANODE

3

CATHODE

4

GND

5

VO

6

VCC

U3

OPTO-ISO-TLP118

C7

0.1uF

R7

1K

R8

150

1

3

2

4

S1

SW-TACT-PTS645SM43SMTR92

R11

10K

1

T1

1

T2

1

T3

1

T4

D2

TVS-GSOT08C-E3-08

C8

470uF

1

VCC

2

VOUT

3

GND

U5

LDO-5V-TR9058-50GV

C9

1.0uF

C10

1.0uF

C11

8pF

C12

8pF

C13

0.1uF

R9

580

R10

470

R14

470

B

G

R

D1

Y1

16.0MHz

TP1

TP2

TP3

TP4

TP5

C14

470uF

C15

470uF

+VBAT

+VBAT

+VBAT

+5.0V

BLO

BHI

ALO

AHI

+5.0V

+5.0V

SERVO_IN

BUTTON

+5.0V

+5.0V

M+

M-

+VBAT

+5.0V

+VBAT

ICSPDAT

ICSPCLK

SERVO_IN

LED-GREEN

LED-RED

BLO

BHI

ALO

AHI

BUTTON

LIMIT_F

LIMIT_R

GD_FAULT

GD_RESET

+5.0V

LED-GREEN

LED-RED

LED-BLUE

+5.0V

LED-BLUE

Table of contents

Other REV Robotics Controllers manuals