7

®

Step: 1.

Close the manual main

Step: 2.

Recheck all limit circuit wiring for proper operation and correct connection.

Step: 3.

Confirm that the automatic main fuel valves are wired to terminal 7.

Step: 4.

Power the control and electrically check the proper sequence of operation according to the

Operation

section in this bulletin.

Step: 5.

After assuring yourself that all interlocks and valves are properly wired and that the

sequence of operation is correct, open the manual main shut-off valve and proceed cau-

tiously through the boiler light off process. Check all safety interlocks for proper shut down

of the boiler.

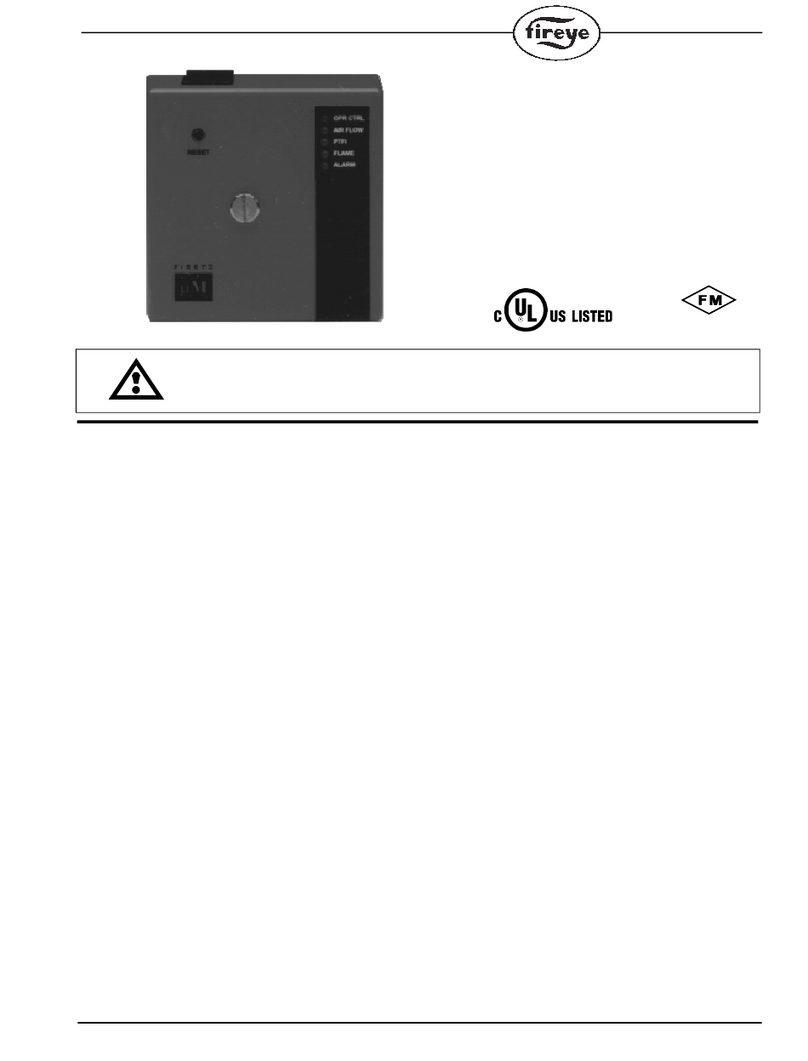

INSTALLATION—UV SCANNERS

Where possible, obtain the Burner Manufacturer's Instructions for mounting the scanner. This infor-

mation is available for most standard burners manufactured. The scanner mounting should comply

with the following General Instructions:

1.

Position the UVI, UV2 scanner within 18 inches of the flame to be monitored, the 45UV5

within 30 inches, closer if possible.

2.

Select a scanner location that will remain within the ambient temperature limits of the UV Scan-

ner. If cooling is required, use an insulating coupling (Fireye #35-69 for UVI, UV2 Scanners,

#35-127-1 for 45UV5) to reduce conducted heat.

3.

The UVI, UV2, 45UV5 Scanners are designed to seal off the sight pipe up to I PSI pressure.

Higher furnace pressures should be sealed off. To seal off positive furnace pressure up to 100

PSI for UVI, UV2 Scanners, install a quartz window coupling (#60-1257). For 45UV5 Scan-

ners, use #60-1199 coupling. Add cooling air to reduce the scanner sight pipe temperature.

4.

Install the scanner on a standard IPS pipe (UVI-

1

/

2

'', UV2-

3

/

8

", 45UV5-1") whose position is

rigidly fixed. If the scanner mounting pipe sights through the refractory, do not extend it more

than halfway through. Swivel flanges are available if desired (#60-302 for UVI, UV2 Scanners,

#60-1664-3 for 45UV5). The sight pipe must permit an unobstructed view of the pilot and/or

main flame, and both pilot and main flames must completely cover the scanner field of view.

5.

Caution: The scanner must not sight the ignition spark- directly, or any part of the burner

that can reflect the spark back to the scanner. The scanner must not see a pilot flame that

is too small to reliably ignite the main flame.

6.

Smoke or unburned combustion gases absorb ultraviolet energy. On installations having nega-

tive pressure combustion chambers, a small hole drilled in the UVI, UV2 sight pipe will assist in

keeping the pipe clean and free from smoke. The 45UV5 has a

3

/

8

" plug in the mounting flange

that can be removed. For positive pressure furnaces, provide clean air to pressurize the sight

pipe, if necessary.

7.

Two UVI or UV2 Scanners may be installed on one burner if it is necessary to view two areas to

obtain reliable detection of the flame. They should be wired in parallel. Only one repetitive self-

checking 45UV5-1009 Scanner may be installed on a burner.

8.

To increase scanner sensitivity with UVI, UV2 Scanners, a quartz lens permits location of the

scanner at twice the normal distance. Use

1

/

2

" x 1

1

/

2

" pipe nipple between UVI Scanner and the

coupling Use

3

/

8

" X close pipe nipple and a

1

/

2

'' x

3

/

8

" bushing on UV2 installations.

9.

Request the assistance of any Fireye Field Office for recommendations of a proper scanner

installation on a non-standard application.

Since oil and gas flames radiate more ultraviolet energy from the base of the flame than from further

out in the flame, this fact should be taken into consideration when installing the scanner sight pipe.

BUT THISNOT THIS NOT THIS

FLAME MUST COMPLETELY COVER

SIGHT OPENING

SCANNER MUST HAVE UNOBSTRUCTED

VIEW OF FLAME

NOT THIS NOT THIS BUT THIS