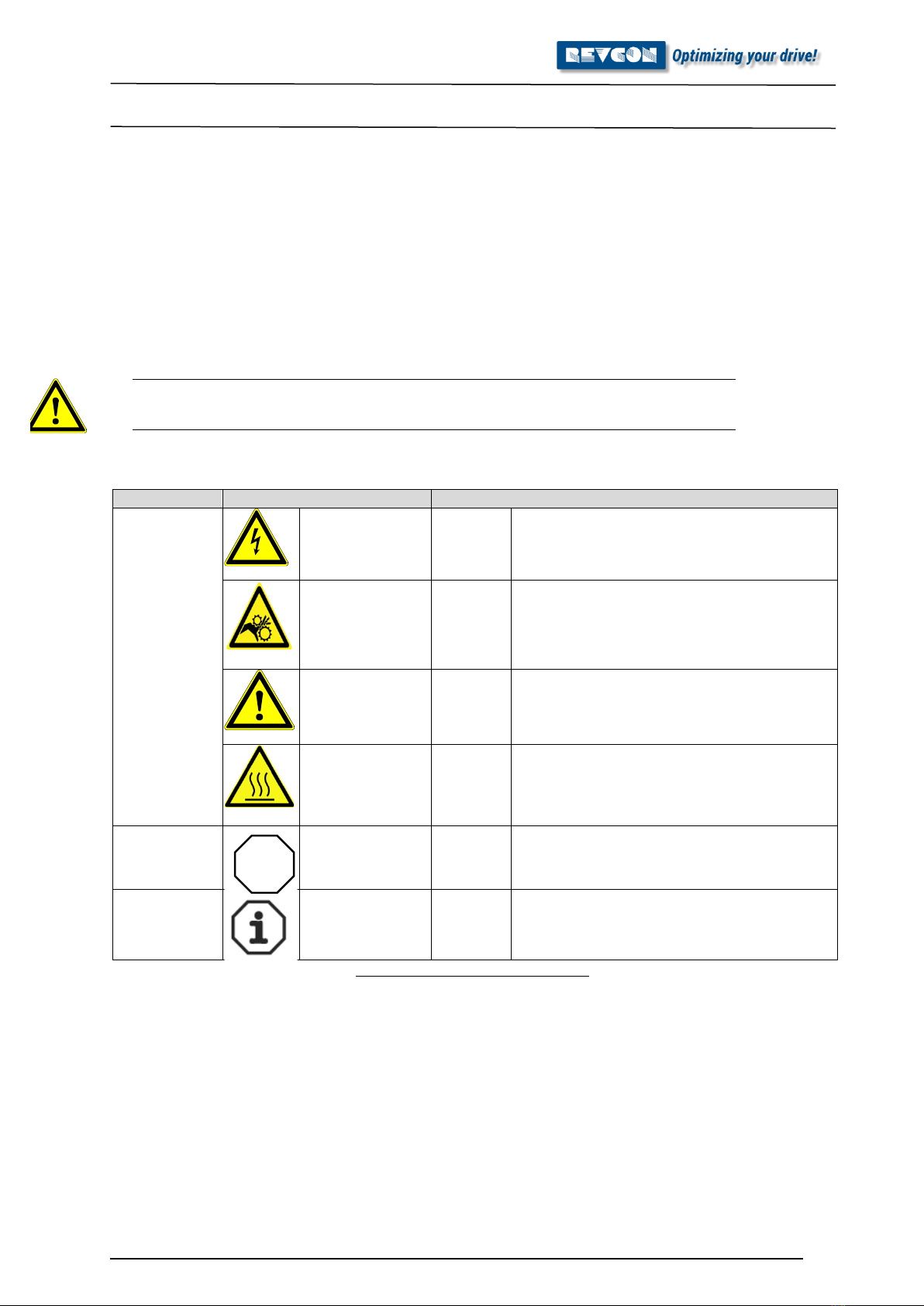

Safety instructions

8Operating instructions RHF

2 Safety instructions

Safety- and application instructions

for propulsion converters

(in conformity with low- voltage directive 2006/95/EG)

During the operation filter modules can own according to their protection

class live, blank and if necessary even movable parts, as well as hot sur-

faces.

The hazard of severe person or property damage exists at not permissible

removal of the required coverage, at inadmissible application, at false In-

stallation or operation.

Further information can be learned from the documentation.

All works for transport for installation and commissioning as well as

maintenance has to be done by specialized staff (IEC 60364 or CENELEC

HD 384 or DIN VDE 0100 und IEC-Report 664 or DIN VDE 0110 and ob-

serve national accident prevention regulations).

Specialized staffs in terms of these fundamental safety instructions are

persons who are acquainted with installation,

assembly, commissioning and operation of the product and who dispose

through their work of the corresponding Qualifications.

2. Conventional application

Filter modules are components that are conventional for the installation in

electrical systems or machines.

At the installation in machines is the start-up of the filter modules (the

start of the conventional operation) prohibited until it is determined that

the machine complies with the regulations of the EG directive 2006/42/EG

(Machine directive); EN 60204 is to observe.

The start-up (the start of the conventional operation) is only allowed under

compliance of the EMC-directive. The filter modules comply with the re-

quirement of the low- voltage directive 2006/95/EG. The technical Data

and also the data of the connecting conditions have to be taken from the

nameplate and the documentation and they have to be necessarily ob-

served.

3. Transport, storage

Notes on transport, storage and appropriate handling must be observed

At non-observance any warranty expires.

The power feedback unit has to be protected from inadmissible stress.

The transport is only valid in original packaging and in the thereon by picto-

grams marked transport position.

In particular during transport and handling no components are allowed to

be bent and / or isolating distances may not be altered. The units are

equipped with electrostatic sensitive devices, which may be damaged by

improper handling. Therefore it has to be avoided to get in contact with

electronic components. If electronic components are damaged mechani-

cally the unit must not be put into operation, as it cannot be ensured, that

all relevant standards are observed. Climatic conditions must be observed

according to prEN 50178.

These safety instructions have to be kept!

The Assembly and cooling of the devices must occur accordingly the in-

structions of the respective documentation.

The filter modules have to be protected of not permissible stress. Par-

ticularly at transport und handling no components must have to be bent

and / or insulation distances being changed. The touch of electric com-

ponents and contacts is therefore to avoid. Electric components must

not be mechanical damaged or destroyed. (Under conditions health

hazards!).

At mechanical defects at electric and other components it is not al-

lowed to start up the device, because a compliance of applied stand-

ards is not longer guaranteed.

5. Electrical connection

At live-line working on filter modules apply national accident prevention

regulations (VBG 4) must be observed. Before any installation- and con-

nection works the system must be operated on dead voltage and ac-

cordingly must be secured.

The electric installation must be performed according to the respective

instructions (e.g. cable cross- section, fuses, connection to the protec-

tive conductor). At usage of the filter module with drive system control

without a safe disconnect from the supplying circuit (according to VDE

0100) all control cables must be included in additional protective

measures (e.g. double insulated or shielded, grounded and insulated).

Notes for the EMV-conform installation – like shielding, grounding, ar-

rangements of filter modules and the installing of conductors – are lo-

cated in the chapter “Installation of these operating instructions”.

These notes must even be observed at CE-marked propulsion convert-

ers. The compliance of the required limit values by the EMV- legislation

is up to the responsibility of the manufacturer of the system or the ma-

chine.

6. Operation

After disconnect of the filter modules of the supply voltage, it is not al-

lowed to touch live-line device parts and line connections because pos-

sibly charged capacitors must not be touched immediately.

During the operation all covers and doors must be closed.

7. Service and Maintenance

The operation of the manufacturer must be observed.

Observe also the product specific safety- and application notes of these operating instructions!