II Contents SYNAX200

DOK-SYNAX*-SY*-07VRS**-PR01-EN-P

Power supply............................................................................................................................4-9

Digital inputs and outputs.........................................................................................................4-9

EMC.......................................................................................................................................4-10

Interfaces ...............................................................................................................................4-10

4.7 Connecting the Power Supply......................................................................................................4-11

4.8 Connecting Inputs and Outputs ...................................................................................................4-11

4.9 Connector Pin Assignments.........................................................................................................4-12

X1 (11-way Phoenix female connector).................................................................................4-12

PROG / COM interface (X10, X16)........................................................................................4-12

BT bus (X15)..........................................................................................................................4-13

4.10 Motion Control Configuration when Using the PPC-R.................................................................4-14

5 Determining Basic Drive Configuration 5-1

5.1 Procedure.......................................................................................................................................5-1

a) Definition of Precision Requirements ..................................................................................5-1

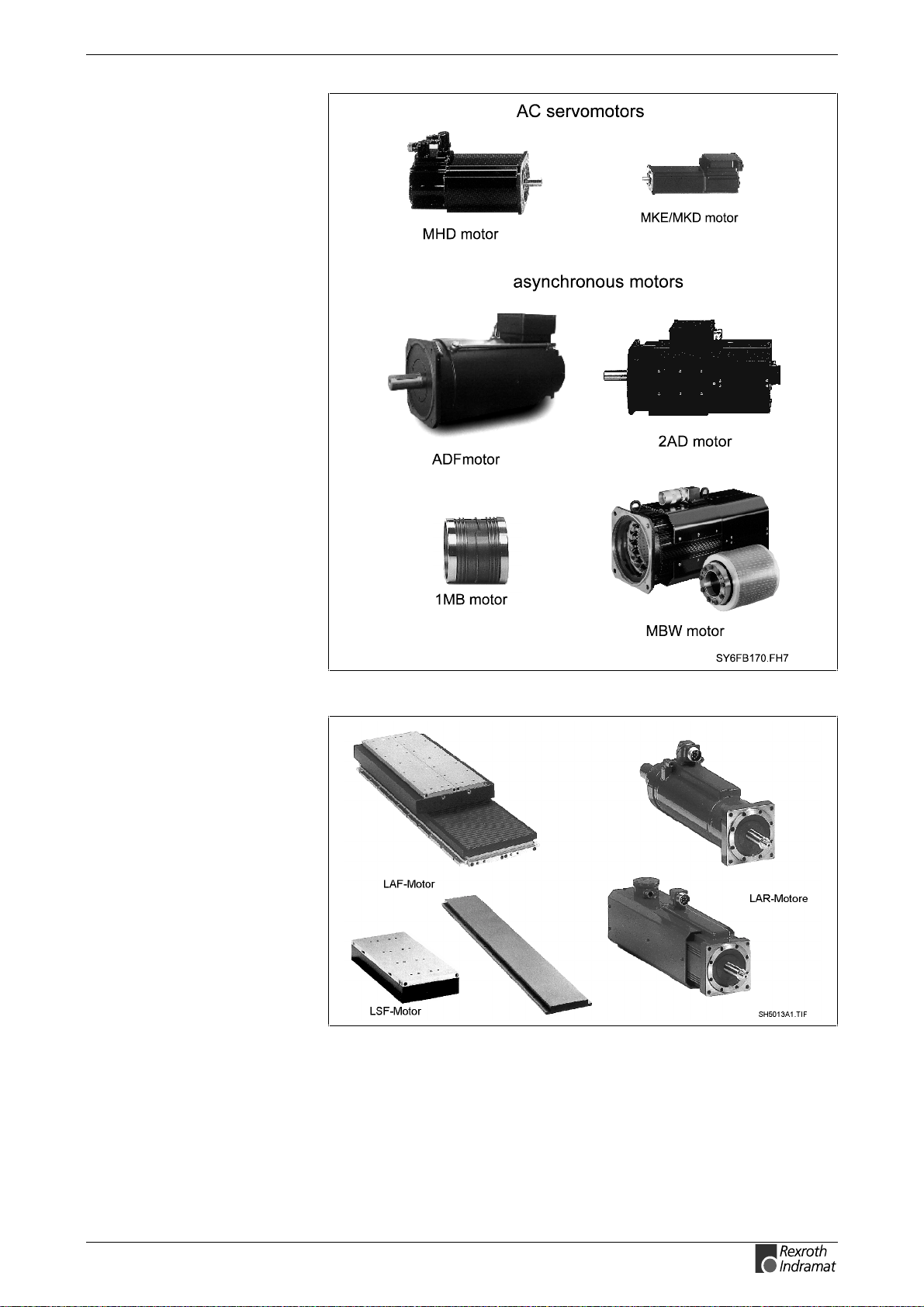

b) Selecting the Suitable Motor/Controller Combinations........................................................5-2

c) Determining the Drive Configuration Labelling....................................................................5-2

5.2 Rotary Axes....................................................................................................................................5-4

Drive with Step-Down Gear and Indirect Position Detection...................................................5-4

Drive with Step-Down Gears and Direct Incremental Position Detection................................5-6

Drive with Step-Down Gear and Direct Absolute Position Detection.......................................5-8

Drive with Indirect Position Detection ....................................................................................5-10

Drive with Direct Incremental Position Detection...................................................................5-12

Drive with Direct Absolute Position Detection........................................................................5-14

5.3 Linear Axes ..................................................................................................................................5-17

Drive with Indirect Position Detection ....................................................................................5-17

Drive with Direct Incremental Position Detection...................................................................5-19

Drive with Direct Absolute Position Detection........................................................................5-21

Drive with Linear Motor and Incremental Position Detection.................................................5-23

Drive with Linear Motor and Absolute Position Detection......................................................5-25

6 Determining the Control-Related Plug-In Cards 6-1

6.1 Determining Parallel I/Os...............................................................................................................6-1

6.2 Combination Options of the External I/O (Drive Internal) ..............................................................6-2

6.3 Determining the Master Axis..........................................................................................................6-3

6.4 Determining Analog Inputs.............................................................................................................6-6

6.5 Master Axis Position Output...........................................................................................................6-6

SSI Emulation ..........................................................................................................................6-6

Incremental Encoder Emulation...............................................................................................6-7

6.6 Encoder Branching DGA 01.2 for Encoders with Sinusoidal Voltage Signals 1Vss......................6-8

General ....................................................................................................................................6-8

Terminal Diagram ....................................................................................................................6-9

Technical Data.......................................................................................................................6-10

7 Drive Configurations 7-1

7.1 General Informations......................................................................................................................7-1