1 SAFETY

1.1 INTRODUCTION

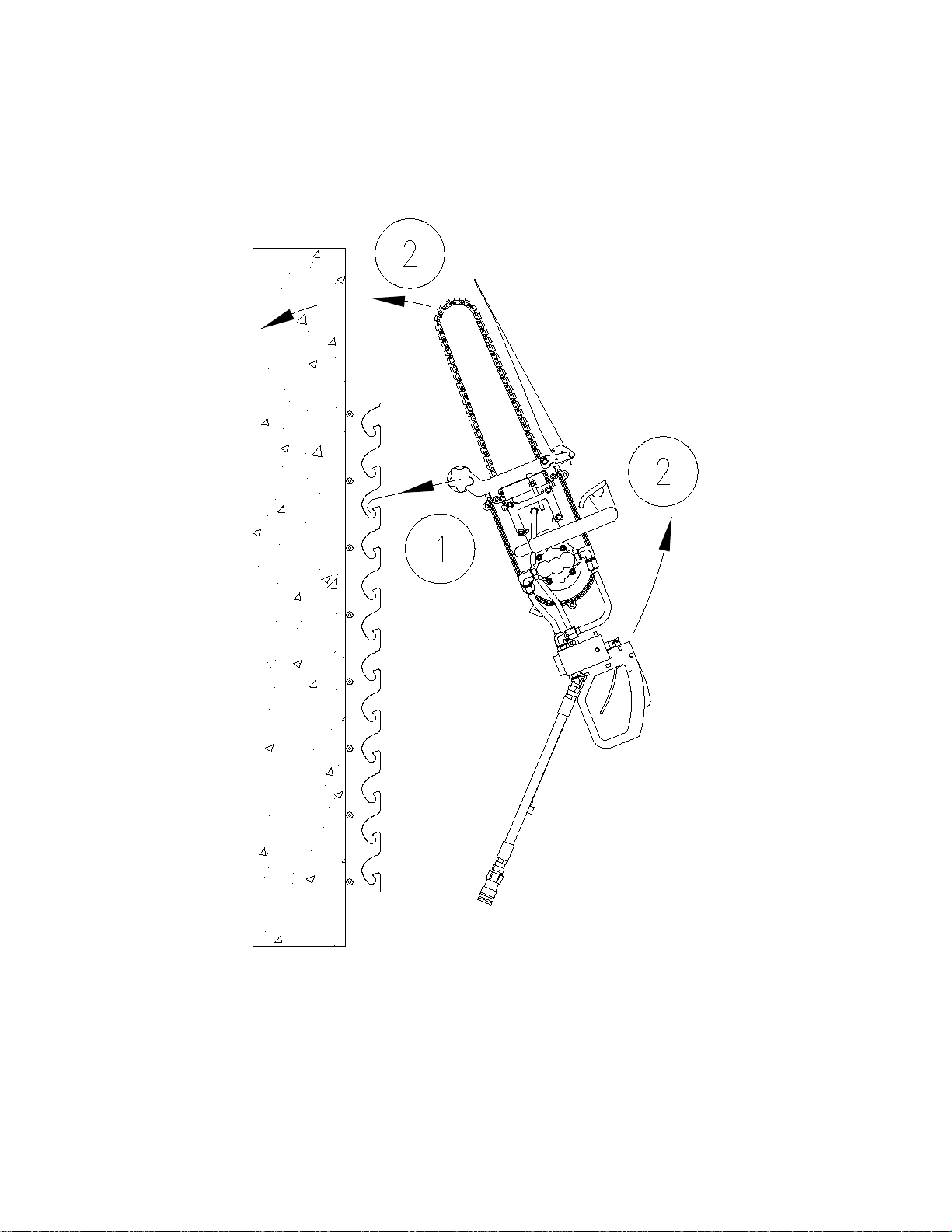

Your Reimann & Georger Corporation C150 Speedhook enables straight line cutting with reduced chain wear and operator

fatigue. The C150 Hydracutter mounted on the Speedhook is a safe, well-designed and well-built system. However, the

system can still malfunction or become hazardous in the hands of an inexperienced and/or untrained user. Therefore, read

this manual and related equipment manuals thoroughly before using your Speedhook to provide maximum safety for all

operating personnel, and to get the maximum benefit from your equipment.

1.2 SAFETY DEFINITIONS

A safety message alerts you to potential hazards that could injure you or others or cause property damage. The safety

messages or signal words for product safety signs are DANGER, WARNING, and CAUTION. Each safety message is

preceded by a safety alert symbol and is defined as follows:

DANGER: Indicates an imminently hazardous situation which, if not avoided, will cause death or serious injury. This

safety message is limited to the most extreme situations.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury. It

may also be used to alert against unsafe practices that may result in property-damage-only accidents.

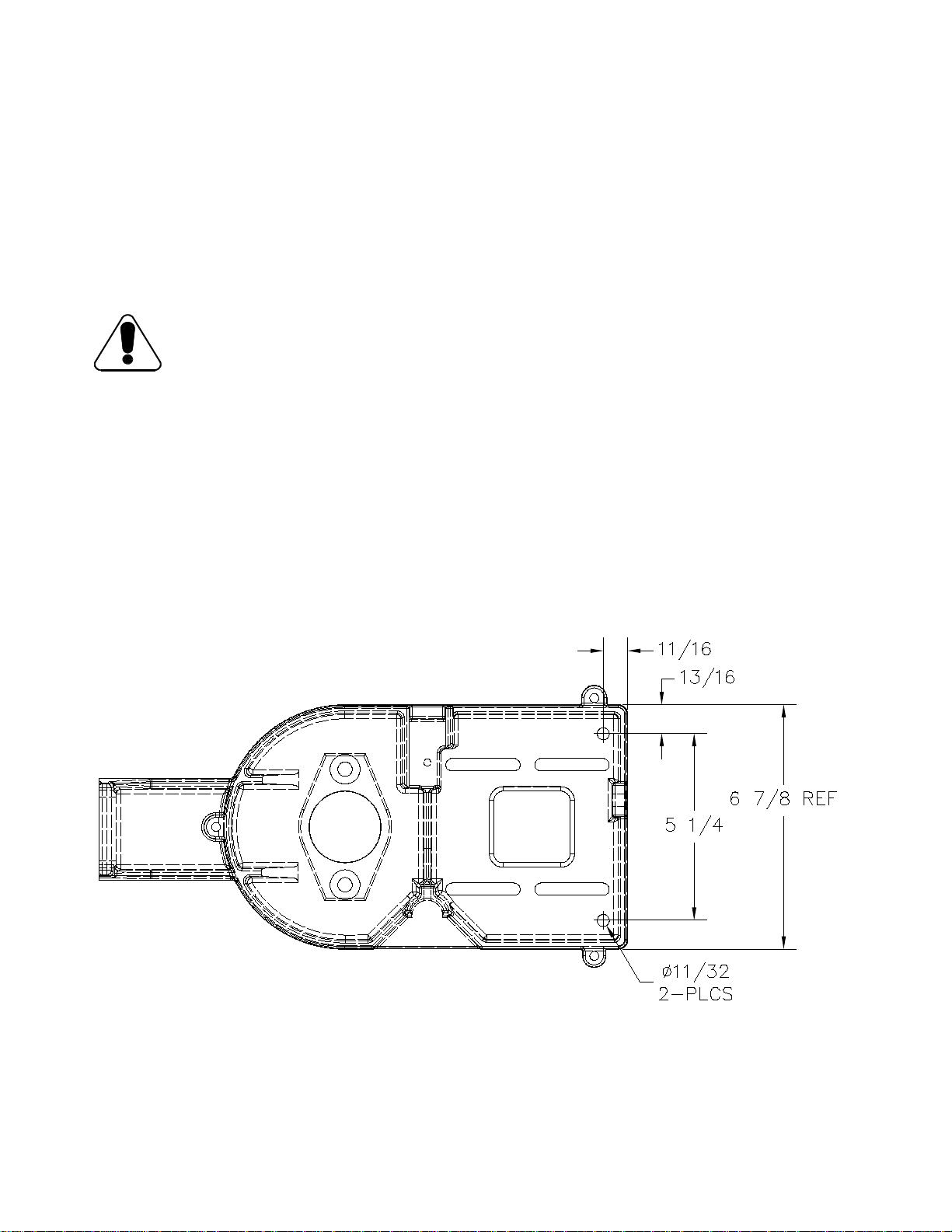

1.3 SAFETY LABELS

These labels warn you of potential hazards that could cause injury. Read them carefully. If a label comes off or becomes

illegible, contact Reimann & Georger Corporation for a free replacement.

1.4 SAFETY RULES

WARNING:

OBSERVE ALL THE SAFETY RULES IN THE C150 HYDRACUTTER MANUAL IN

ADDITION TO THOSE LISTED BELOW. FAILURE TO DO THIS CAN CAUSE SERIOUS

PERSONAL INJURY AND/OR EQUIPMENT DAMAGE.

1. Operators must be thoroughly trained before using the Speedhook and associated C150 Hydracutter. A trained person

is one who has read and thoroughly understands this instruction manual and related equipment manuals and, through

training and experience, has shown knowledge regarding the safe operational procedures.

2. Do not use the Speedhook or the saw if either shows any signs of damage.

3. Never set up the Speedhook in an explosive atmosphere and/or near combustible material that could be ignited by a

spark.

4. Sawing area must be kept clear of unauthorized personnel at all times. On both sides of a wall, place barricades or

secure the area with signs and a roped boundary to prevent personnel injury.

5. Use all personal protective equipment as defined by the employer. As a minimum, safety glasses, safety shoes, hard

hat, and gloves must be worn.

6. Do not set up the Speedhook or start cutting without first de-energizing electrical wiring near the cutting site or

imbedded in the concrete.

7. Before cutting through a wall, check both sides for possible obstructions.

8. Always operate the saw in a well-ventilated area.

1